Layered secondary battery

A storage battery and negative electrode technology, applied in secondary batteries, small-size batteries/battery packs, large-size batteries/battery packs, etc., can solve the problem of separators electrically contacting the shell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0060] A slurry consisting of 63 parts by mass of lithium-manganese composite oxide, 4.2 parts by mass of acetylene black (number average particle size of 7 μm), 2.8 parts by mass of polyvinylidene fluoride, and 50 parts by mass of N-methyl-2-pyrrolidone.

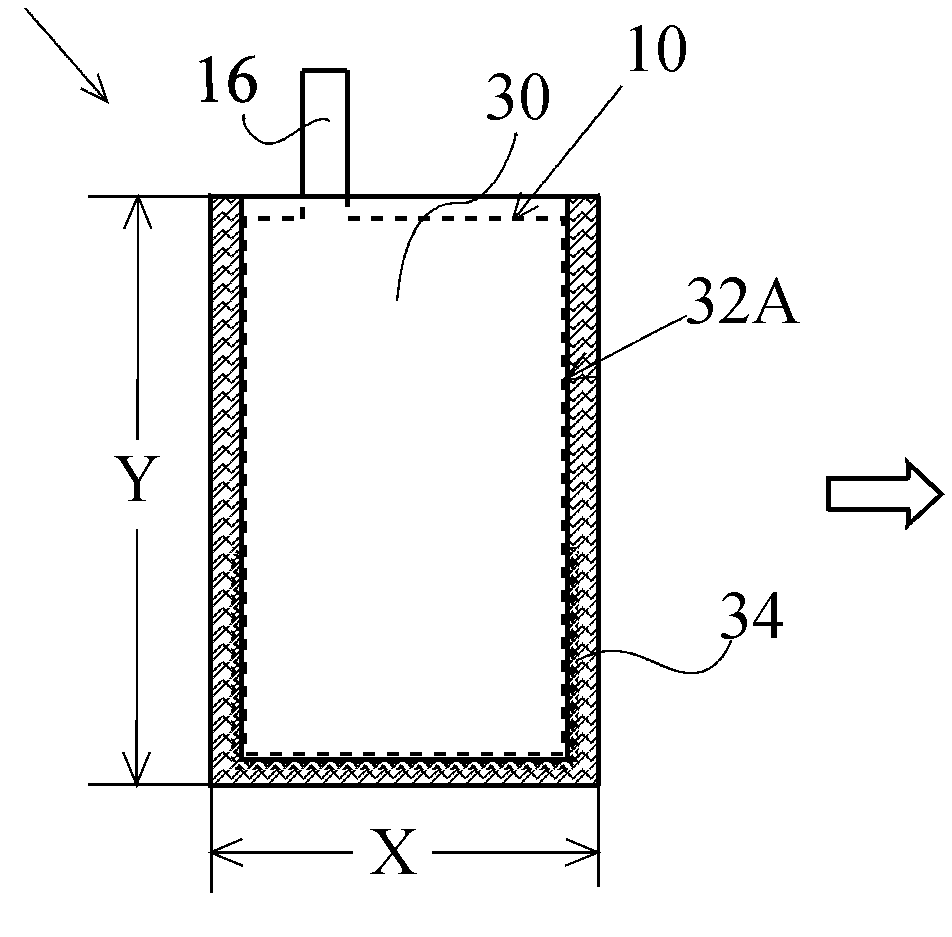

[0061] The slurry was applied across the width of the 20 micron thick, 150 mm wide aluminum foil as a current collector and intermittently along the length of the foil over a length of 130 mm, with the uncoated length being 20mm. The coated collector was dried and pressed to form a 180 micron thick positive electrode active material layer.

[0062] An electrode lead terminal of 13 mm wide by 17 mm long was formed in each uncoated area so that the positive electrode was coated in its 65 mm wide by 125 mm long area.

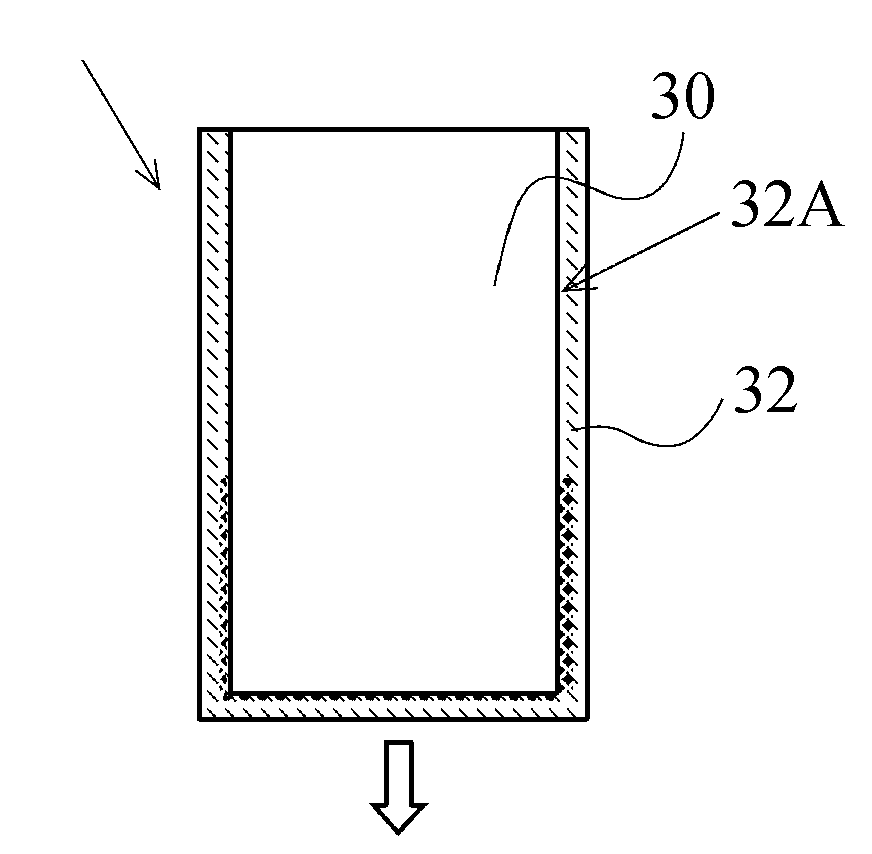

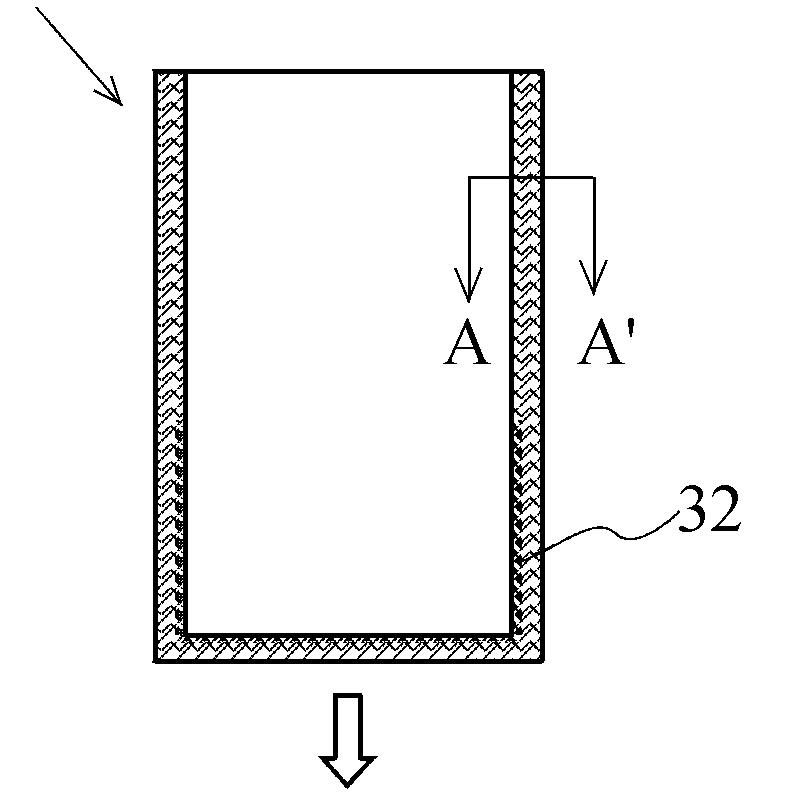

[0063] Each positive electrode was covered with a 25 micron thick polypropylene separator and bonded to the separator by heat fusion on the 1.5 mm end of the positive electrode.

[0064] Next, a 30-micron-thi...

example 1

[0068] Ten lithium ion batteries were produced in the same manner as in Example 1, except that the synthetic resin tape with an adhesive layer was not applied across the junction area of the separator. In the same overcharge test, 4 of the Li-ion cells produced produced smoke when charged to 25V at 1C current.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com