Three-layer encrusting machine with interchangeable horizontal and vertical feeding modes

A feeding method and filling machine technology, which is applied in the direction of food forming, food coating, food science, etc., can solve the problems of unstable product weight, uneven feeding, and damage to the characteristics of ingredients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

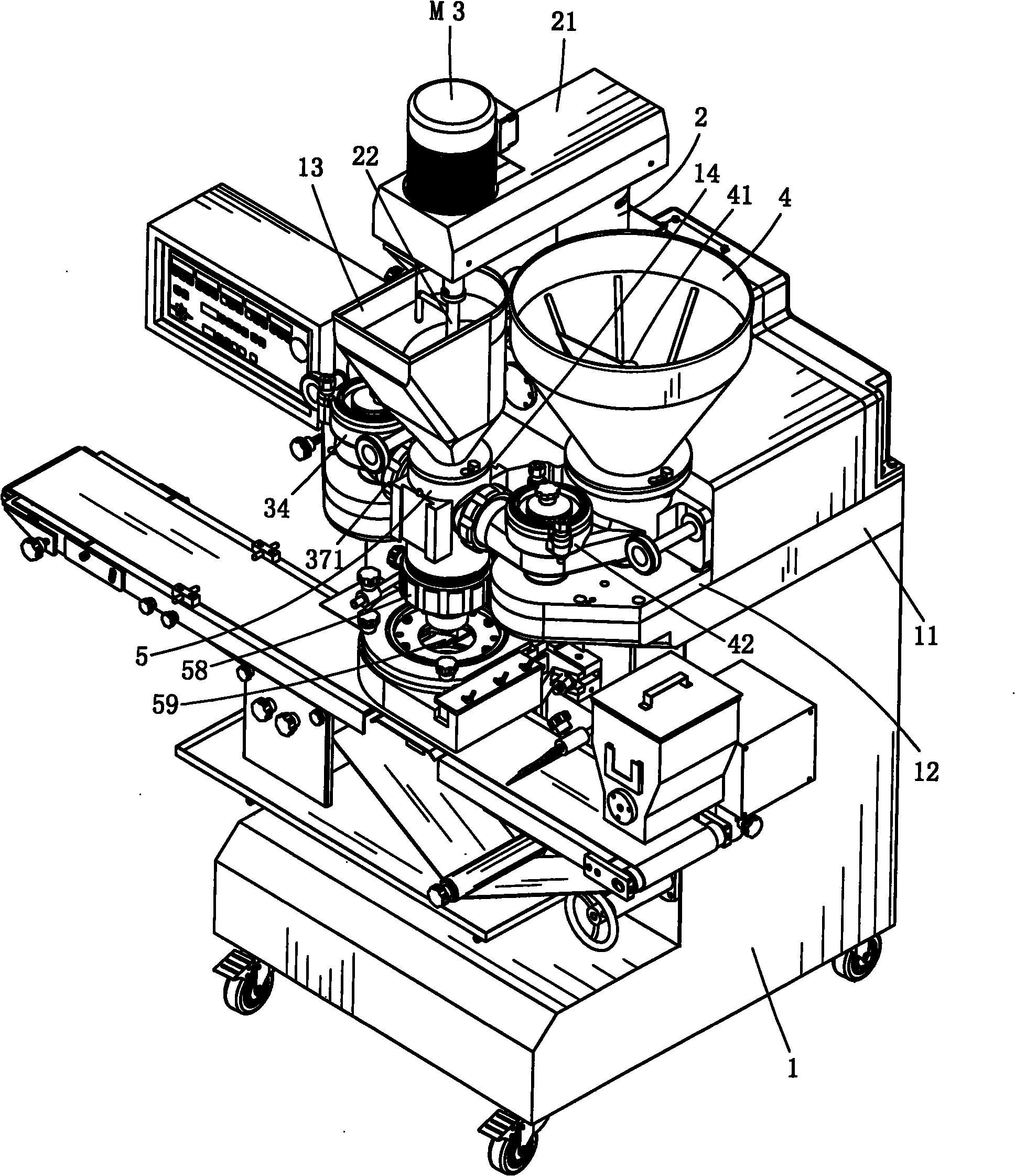

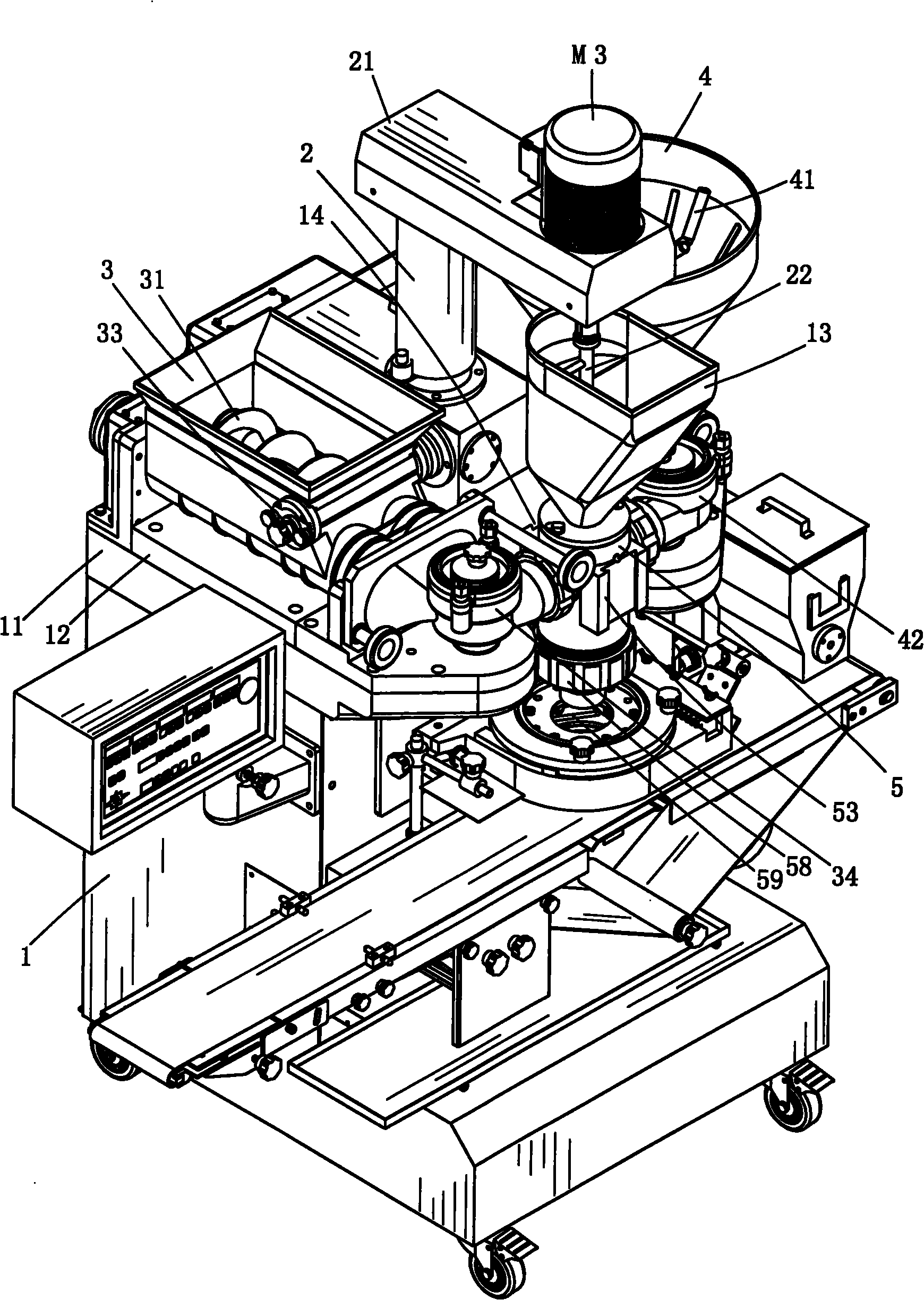

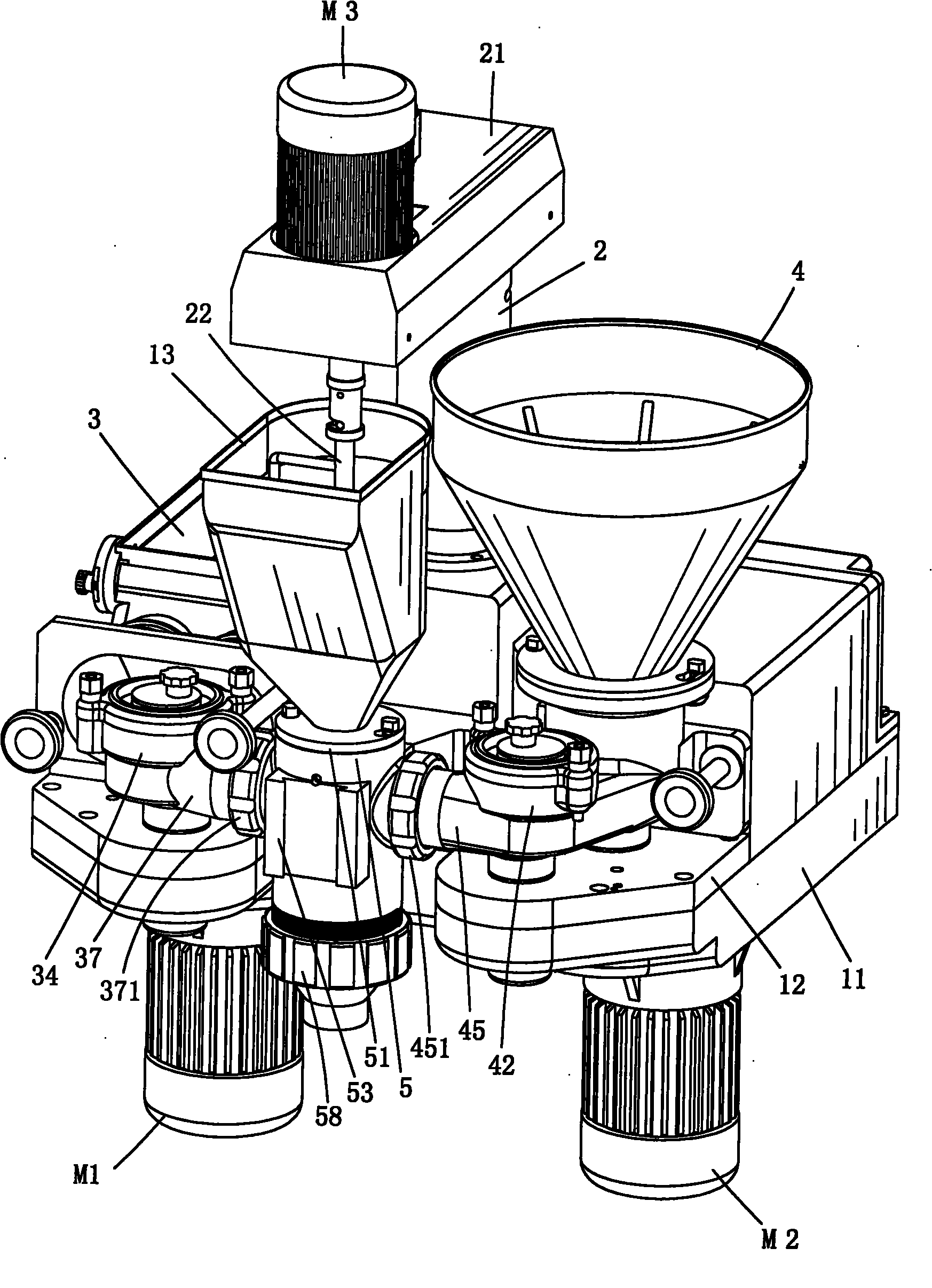

[0036] Please refer to figure 1 as well as figure 2 As shown, the present invention has a three-layer stuffing machine with interchangeable horizontal and vertical feeding methods, which is provided with a transmission case 11 above the machine table 1, and a drive motor M1 and M2 are respectively provided on both sides below the transmission case 11 ( see image 3 ), the upper part of the transmission case 11 is a transmission case upper cover 12, and the transmission case 11 is equipped with a plurality of transmission gears connected with the driving horses M1 and M2 and other transmission mechanisms, and the top of the transmission case upper cover 12 is near the center and on both sides. Column 2, horizontal material guide groove 3 and vertical material guide cylinder 4, a beam 21 is extended above the column 2, a drive motor M3 is provided at one end, and the main shaft of the drive motor M3 extends downward by a The screw 22 extends into the middle seat guide cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com