High-density non-stop cotton bundling forming machine with adjustable cotton bundle diameter and method

A forming machine and high-density technology, applied to agricultural machinery and tools, parts of strapping machinery, picking machines, etc., can solve problems such as high cost, low harvesting efficiency, and non-continuous operation of square cotton pickers, and achieve storage The effect of convenient transportation, uniform quality, and improved automation and intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

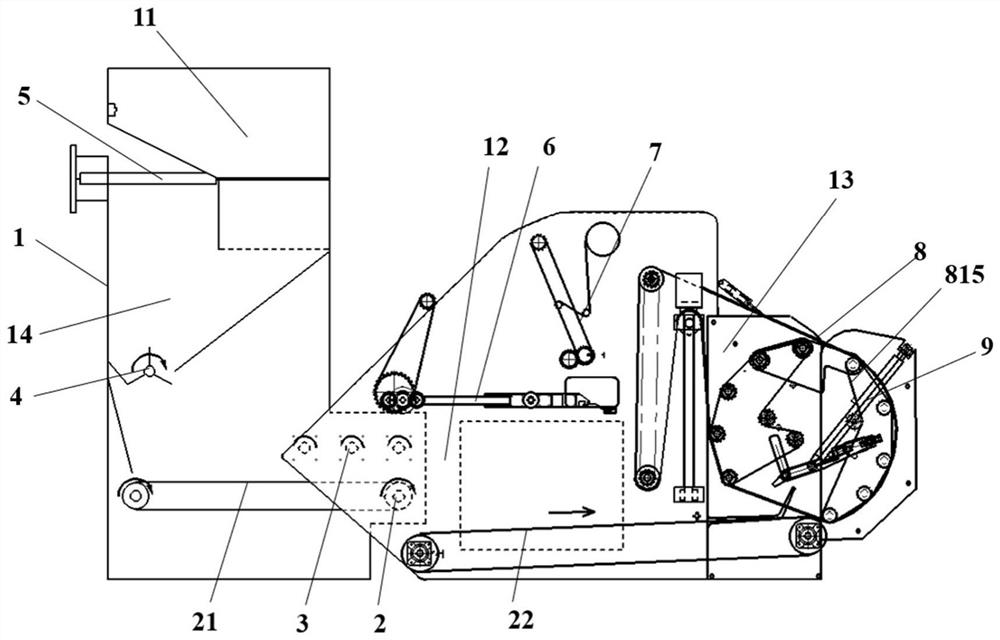

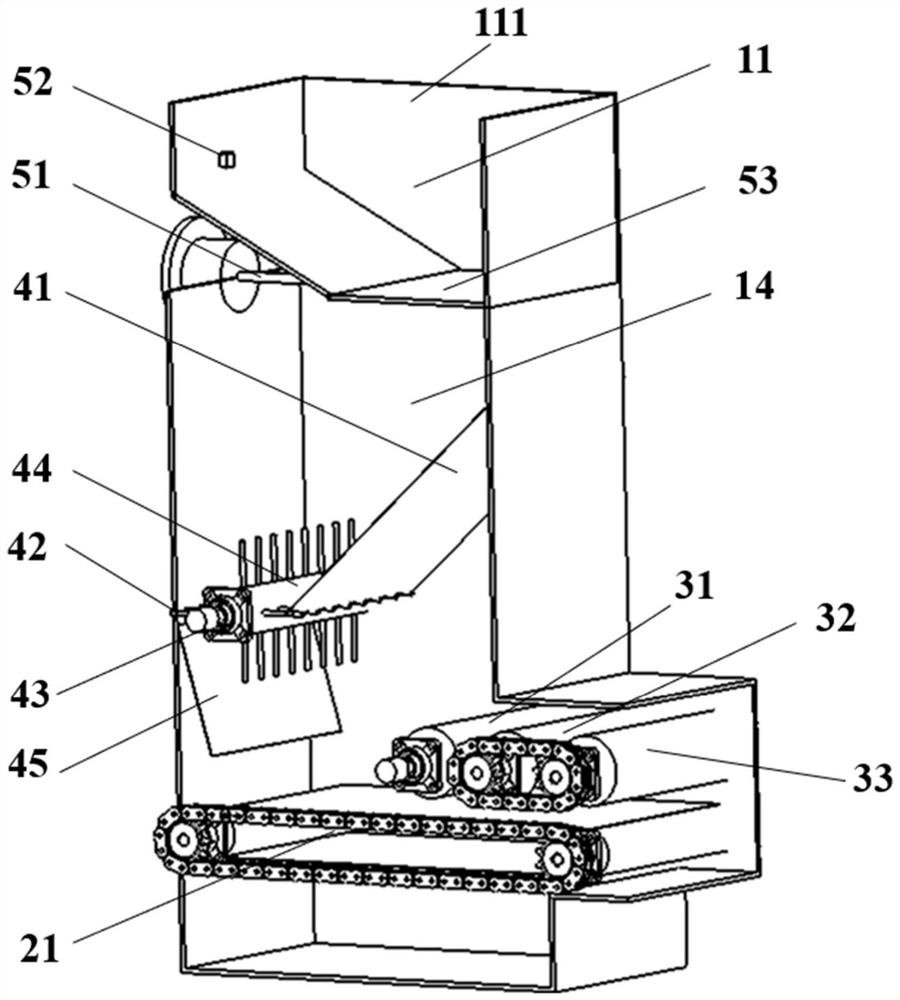

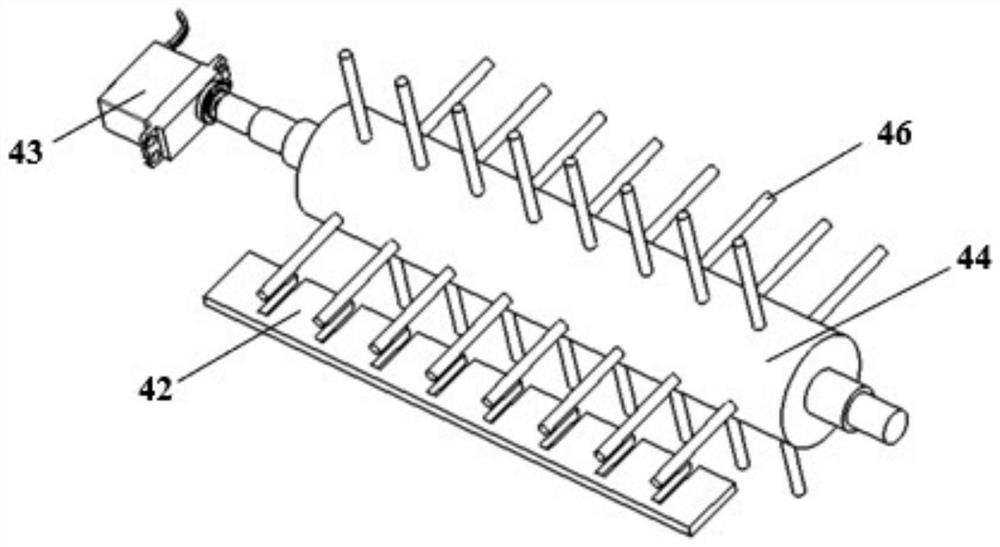

[0102] Such as figure 1 As shown, a high-density non-stop cotton baling forming machine with adjustable cotton bale diameter includes a housing 1, a conveying device 2, a cotton pressing device 3, a cotton roller opening device 4, a cotton collecting and releasing device 5, a cutting Net device 6, net winding and feeding device 7, forming device 8, hydraulic device 9 and PLC control system.

[0103] The housing 1 is sequentially divided into a cotton collecting bin, a pressing cotton conveying bin 12 and a bundling and forming bin 13 according to the operating procedures;

[0104] The top of the cotton collection bin is provided with a cotton inlet 111; as Figure 8 As shown, the bundling and forming bin 13 is an opening and closing structure controlled by a hydraulic device 9 , and is divided into a front fixed bin 131 and a rear opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com