Drum feeder for ball mill and feeding method thereof

A ball mill and feeder technology, which is applied in the field of ball mill drum feeder and its feeding, can solve the problems of easy material blockage, impact on production efficiency, high uniformity requirements, etc., so as to eliminate shutdown maintenance and improve production efficiency , to meet the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

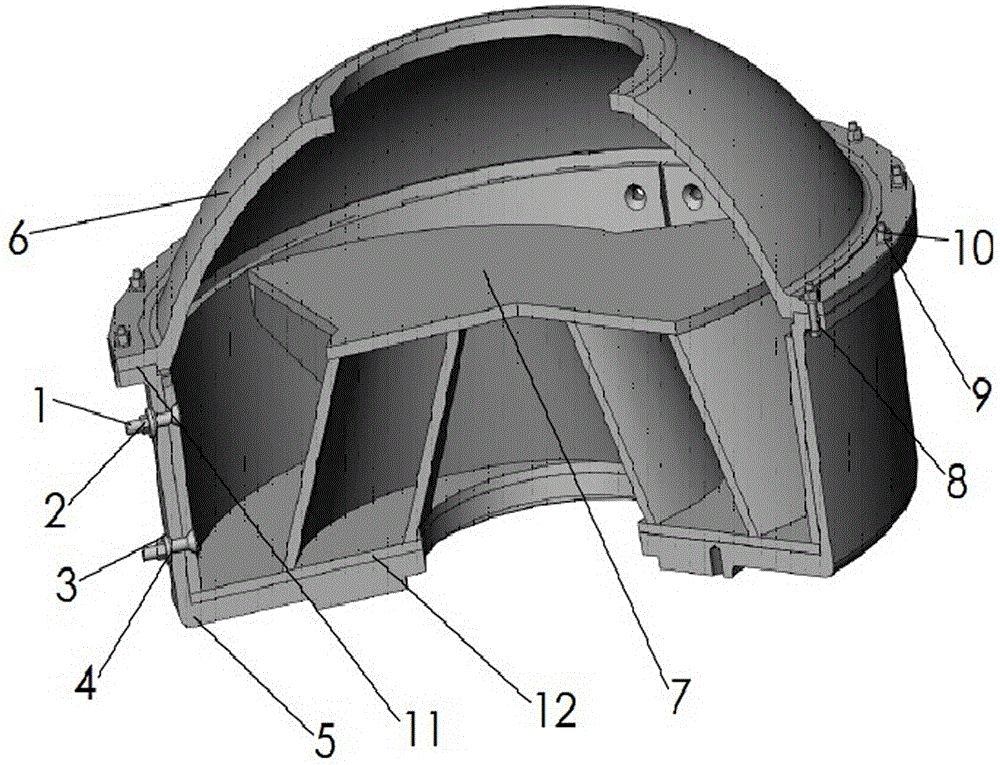

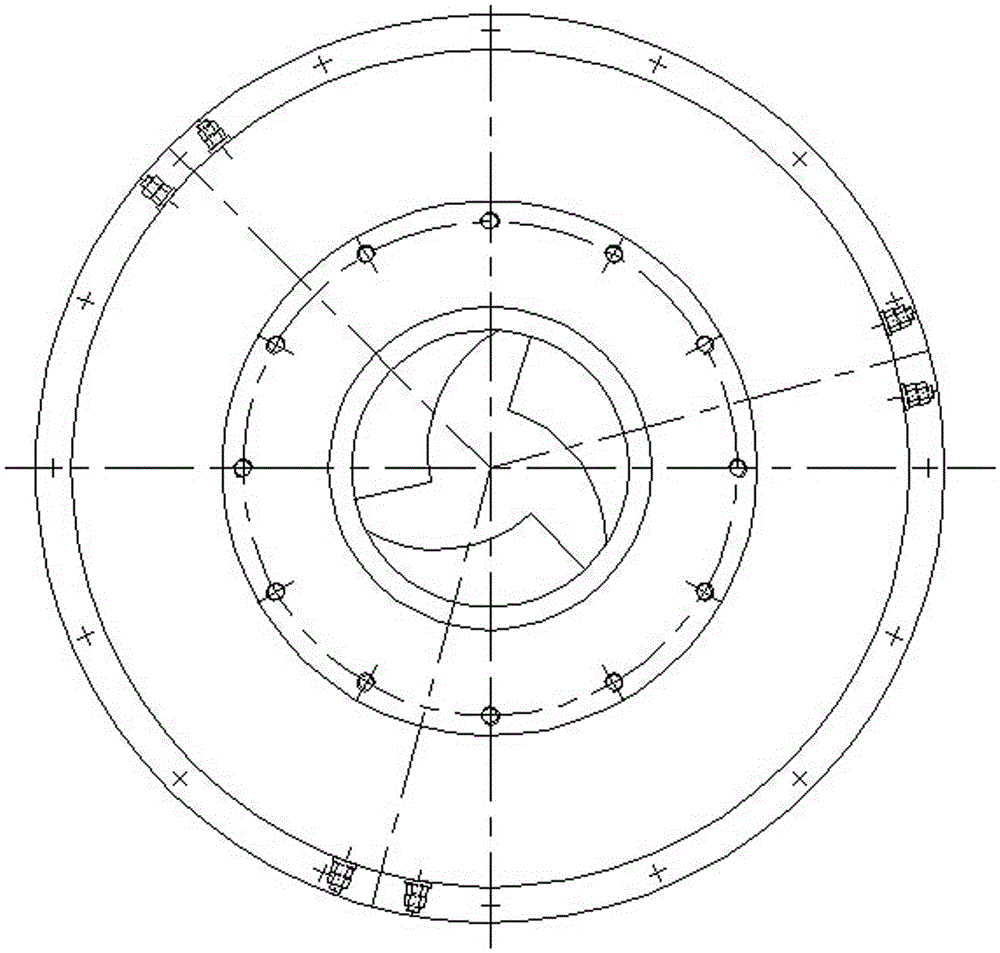

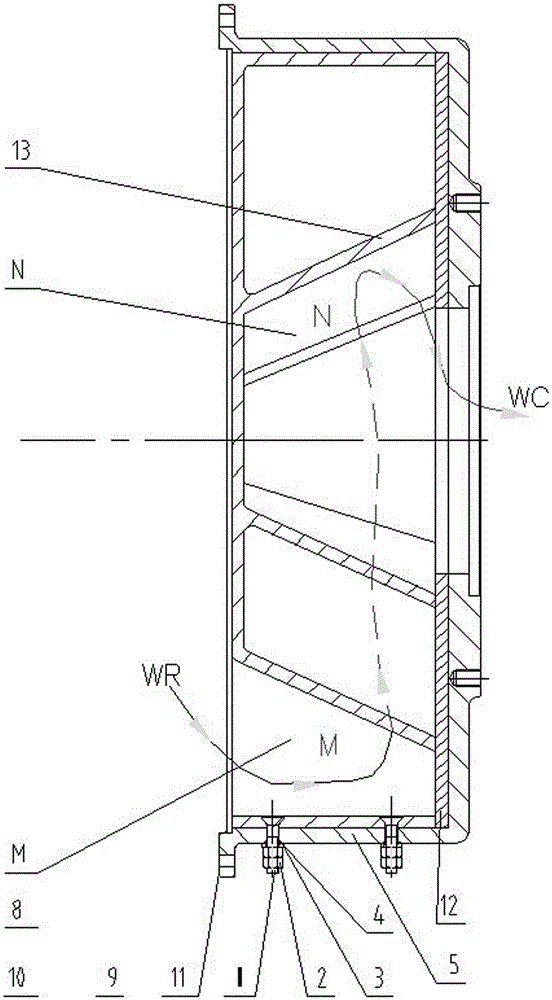

[0019] Example 1 as Figure 1-5 Shown: a ball mill drum feeder, which is composed of a cylindrical feeding shell 5, a feeding end cover 6 matched with it, a bottom liner 12 and a three-port spiral body 7; 5. The bottom lining plate 12 and the three-port spiral body 7 matched with the inner cavity are loaded into the open end of the cylindrical feeding shell 5, and the feeding end cover 6 is connected to the cylinder through the 2# bolt 8, the spring washer 9 and the 2# nut 10. Tightly connect the bottom liner 12 and the three-port spiral 7 with the inner bottom of the cylindrical feed shell 5; the center of the bottom of the cylindrical feed shell 5 is provided with a circular material outlet WC and the boss and mounting screw hole that are connected with the inlet end cover of the ball mill; the three-port spiral body 7 is an integral wear-resistant casting composed of three helical blades 13 in an annular array, and enters from the material inlet WR of the feed end cover 6 ...

Embodiment 2

[0022] Example 2 as Figure 1-5 Shown: adopt the feeding method of a kind of ball mill drum feeder described in embodiment 1, comprise:

[0023] ① After the ball mill starts, start the belt conveyor to feed the drum feeder;

[0024] ②When the cylinder of the ball mill rotates one turn, the three-port screw (7) of the drum-shaped feeder fixedly connected to the end cover of the ball mill feeds the material to the ball mill three times. Improve the production efficiency of the ball mill;

[0025] ③Before the ball mill is shut down, first shut down the belt conveyor for conveying materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com