Tool special for turning excircle of fork piece

A technology for turning outer circles and forks, which is applied in the field of parts processing tooling and mechanical processing, and can solve problems that affect the processing quality of forks, such as the initial unbalance of the drive shaft assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

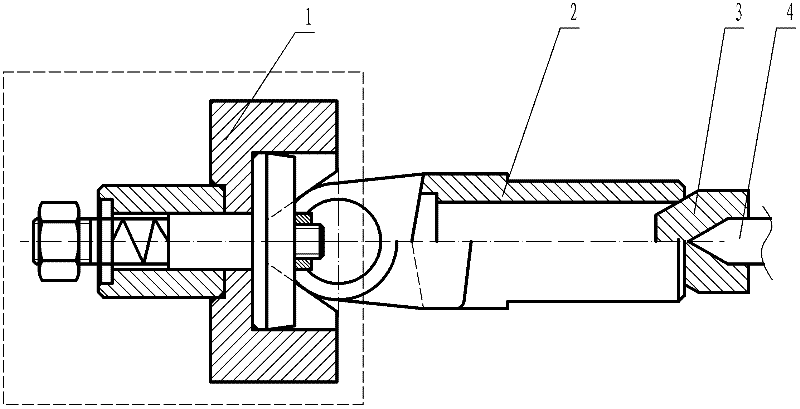

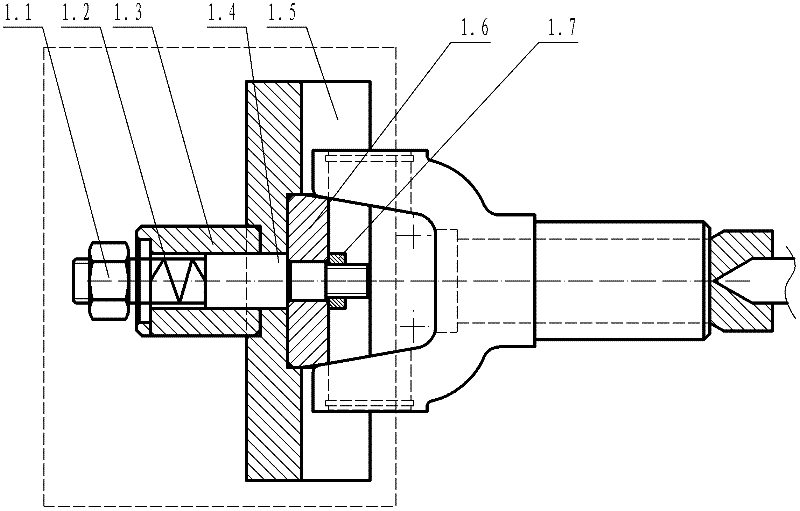

[0009] Such as figure 1 , 2 As shown, the first nut 1-1 of the present invention is threadedly connected with the mandrel 1-4, the spring 1-2 is sleeved on the mandrel 1-4, the outer circle of the mandrel 1-4 is connected with the inner hole of the positioning sleeve 1-3 Clearance fit, the outer circle of the positioning sleeve 1-3 is matched with the inner hole of the V-shaped block 1-5 and then welded together; the outer circle of the positioning block 1-6 is clearance-fitted with the inner hole of the V-shaped block 1-5, and the inner hole and the mandrel The outer circle of 1-4 is matched and locked with the second nut 1-7, and the V-shaped block 1-5 is locked on the connecting plate of the lathe spindle through bolts; the two ears of the sliding fork 2 are on the V-shaped block 1-5, and the inner The empty crotch is positioned with the positioning blocks 1-6; the top sleeve 3 and the top 4 are matched with a taper, and the top sleeve 3 tightens the inner hole of the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com