Inner wall shot peening strengthening treatment process and device

A shot peening and processing device technology, applied in the direction of improving process efficiency, can solve problems such as pipeline failure, and achieve the effects of improved performance, easy implementation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

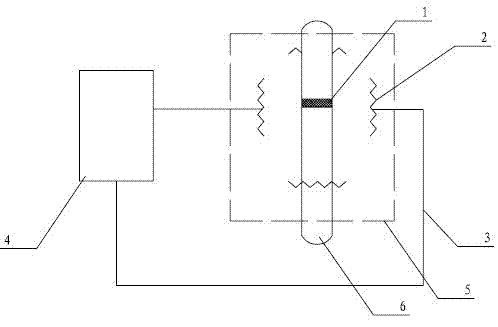

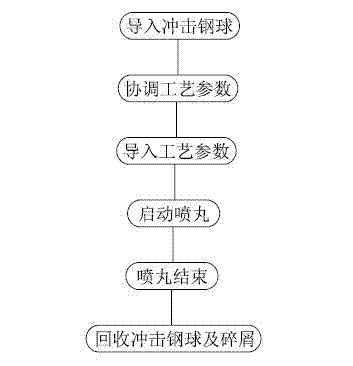

[0022] Embodiment one: see figure 1 , 2 Shown, a kind of inner wall shot peening treatment process, its steps are:

[0023] ⑴ Control the electromagnet through the control system, use the electromagnet to guide the impact steel ball into the impact treatment tube and guide the impact ball to the predetermined shot peening area;

[0024] ⑵According to the pipe diameter, pipe wall thickness, material to be impacted and the diameter of the impact steel ball, coordinate the magnetic magnitude and alternating frequency of the electromagnet, and then guide the impact steel ball to accelerate, and the impact steel ball collides with the inner wall of the pipe to achieve shot peening impact strengthening ;

[0025] (3) After the shot peening impact strengthening is completed, the impact steel balls and debris are recovered by the electromagnet.

[0026] An inner wall shot-peening strengthening treatment device, comprising impact steel ball 1, and electromagnets 2 are respectively s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com