Coating support and coating machine

The technology of a frame body and a flip frame is applied in the field of coating machines, which can solve the problems of low efficiency, pollution of optical components, time consumption, etc., and achieve the effect of improving coating efficiency and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The coating bracket and the coating machine provided by the technical solution will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

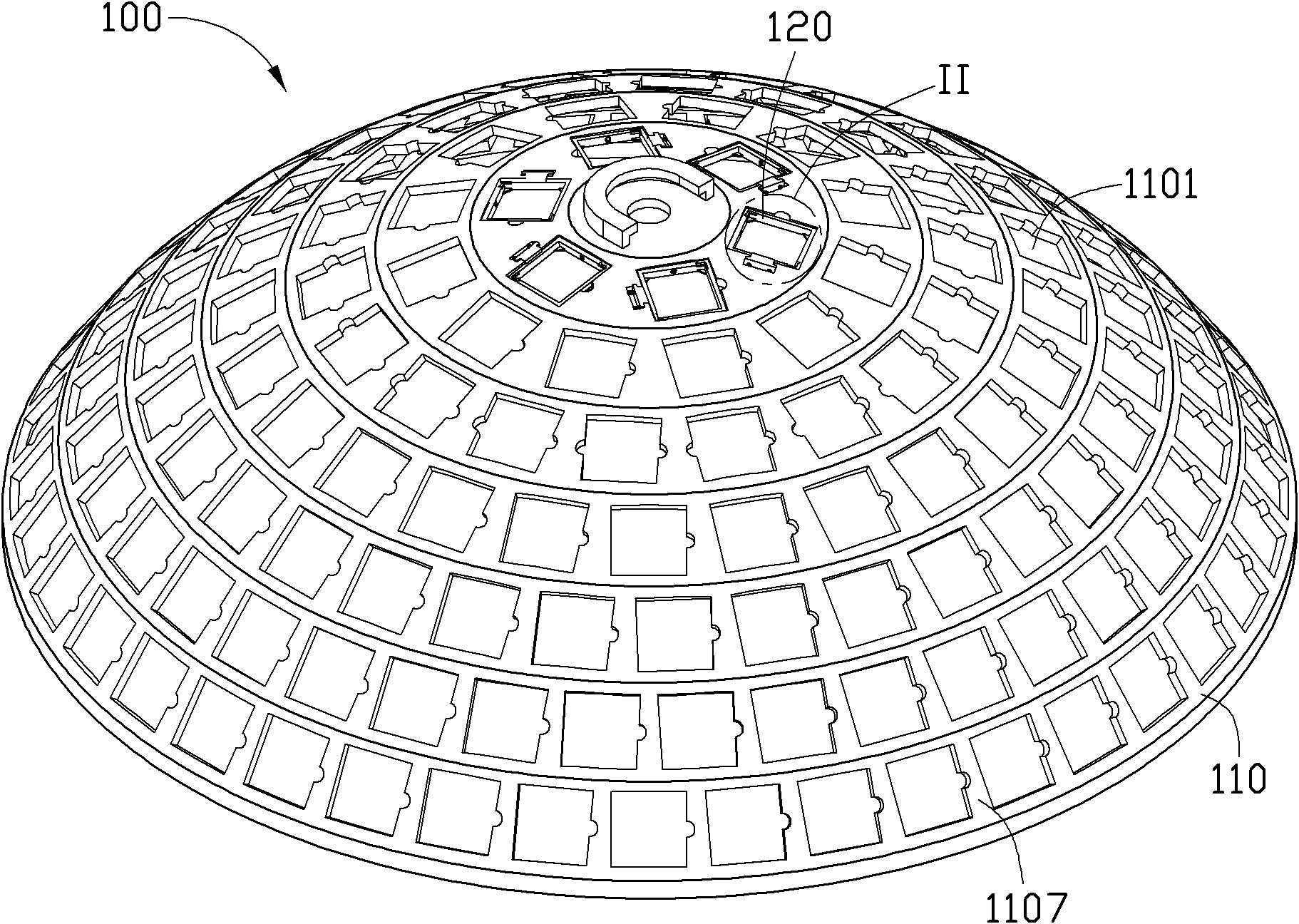

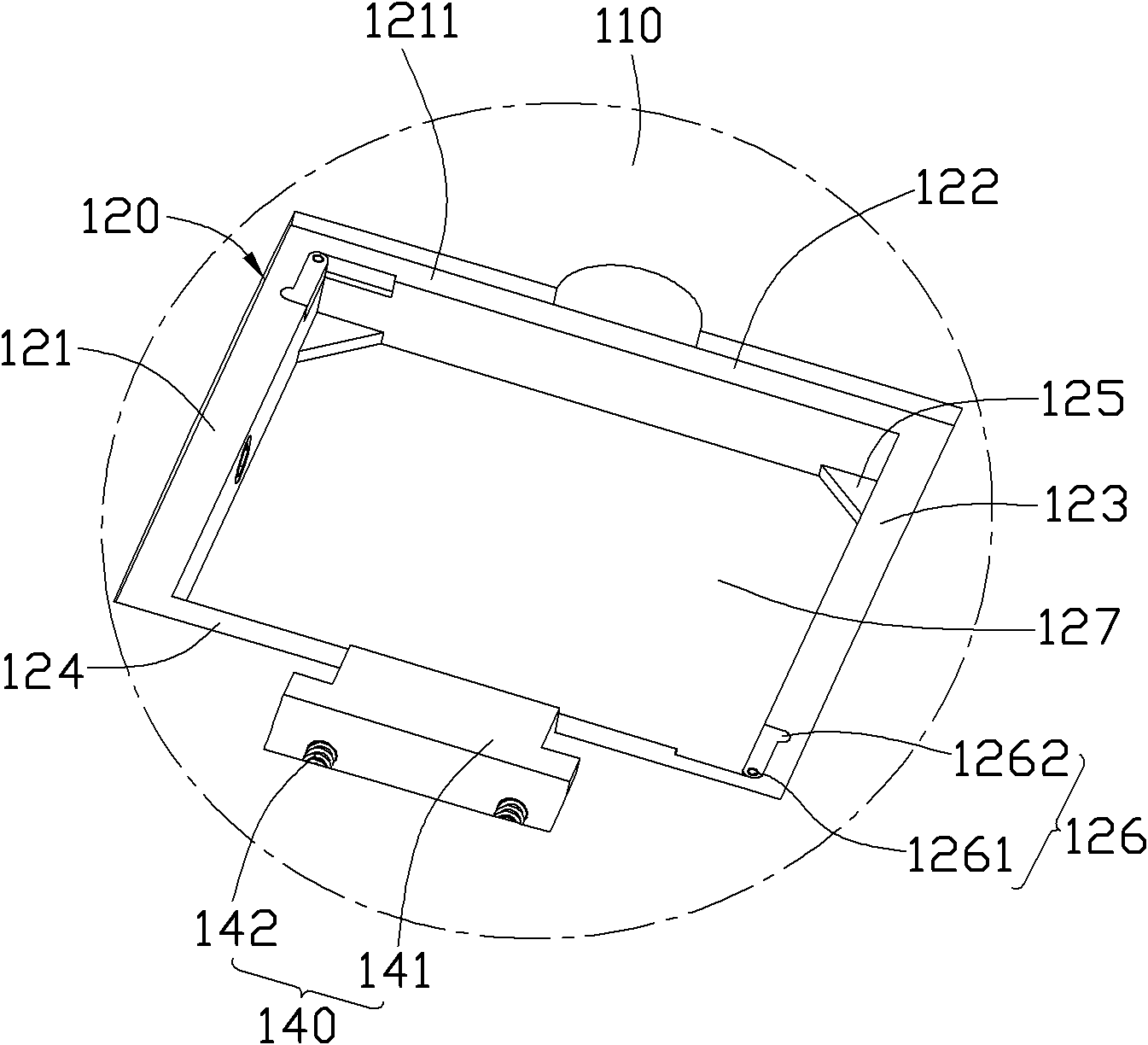

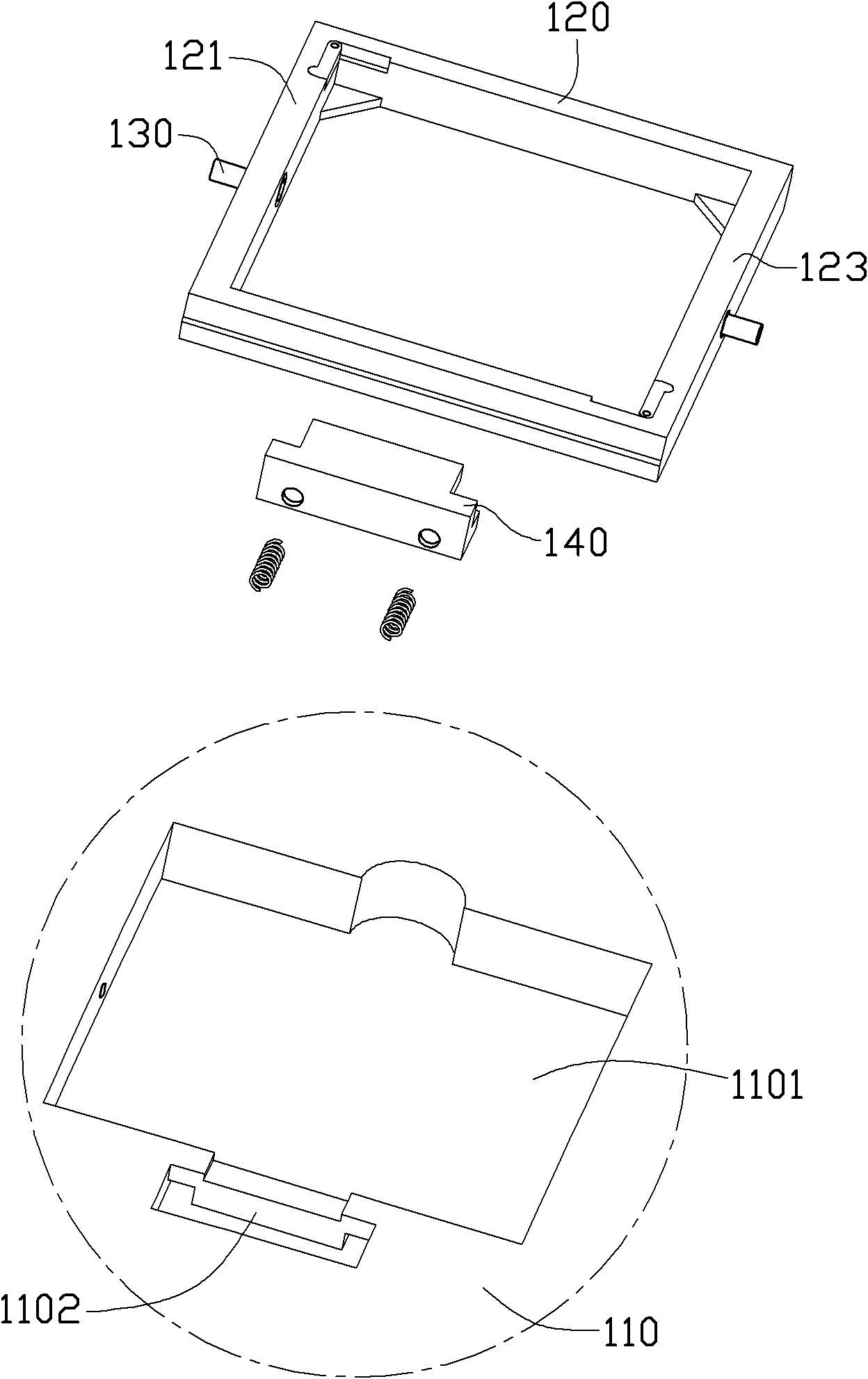

[0046] see figure 1 and Figure 4 , The coating frame 100 provided by an embodiment of the technical solution includes a frame body 110 , a plurality of flip frames 120 , a plurality of fixed shafts 130 and a plurality of locking devices 140 .

[0047] see figure 1 , the frame body 110 is in the shape of a hemispherical surface, driven by a driving device (not shown in the figure), the frame body 110 can rotate around its central axis. The frame body 110 can be made of metal with good thermal conductivity, such as copper, aluminum or stainless steel. The frame body 110 has an outer surface 1107 and has a plurality of square through holes 1101 . The plurality of through holes 1101 pass through the outer surface 1107 and are arranged in a concentric array on the frame body 110 . Each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com