Multi-way reversing valve

A technology for switching valves and valve cores, which is applied to multi-port valves, valve devices, valve details, etc., can solve the problems of low configuration freedom, large switching valves, and redundant space, so as to reduce assembly and processing costs, simplify the structure, and realize Effects of configuring degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Hereinafter, embodiments of the multi-directional switching valve of the present invention will be described with reference to the drawings.

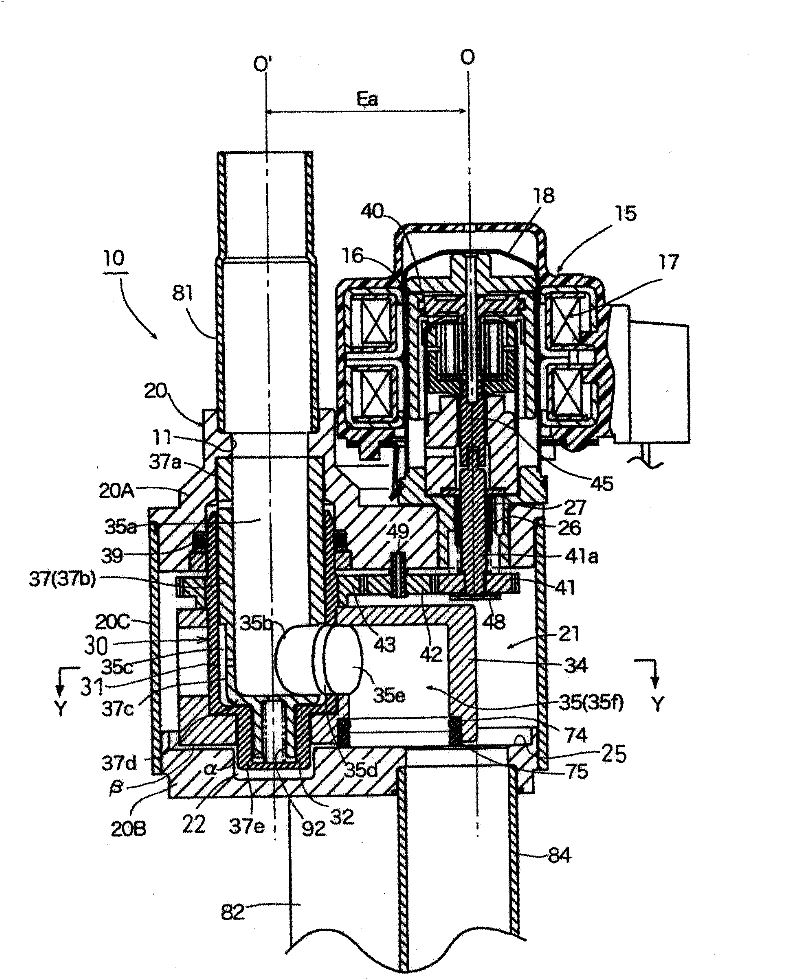

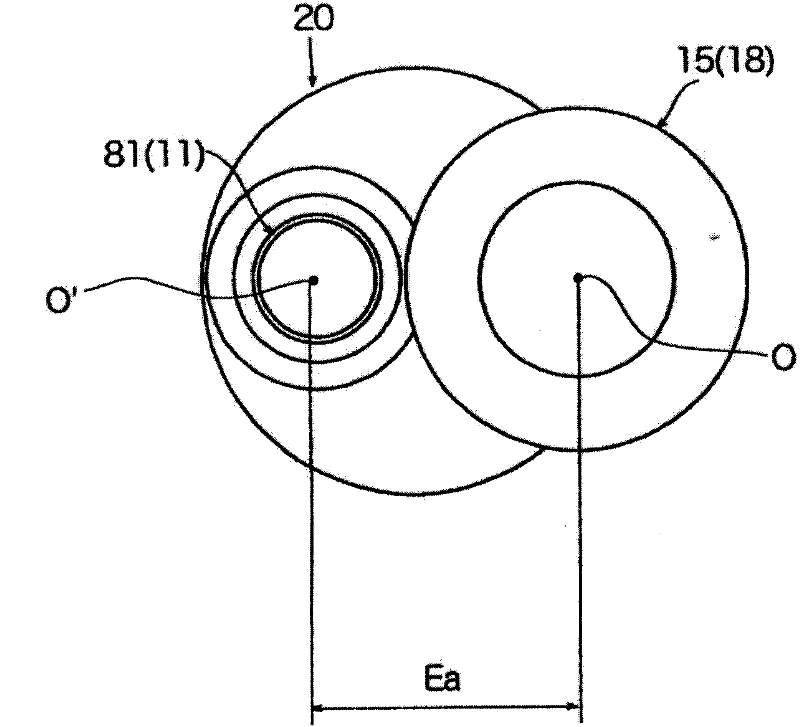

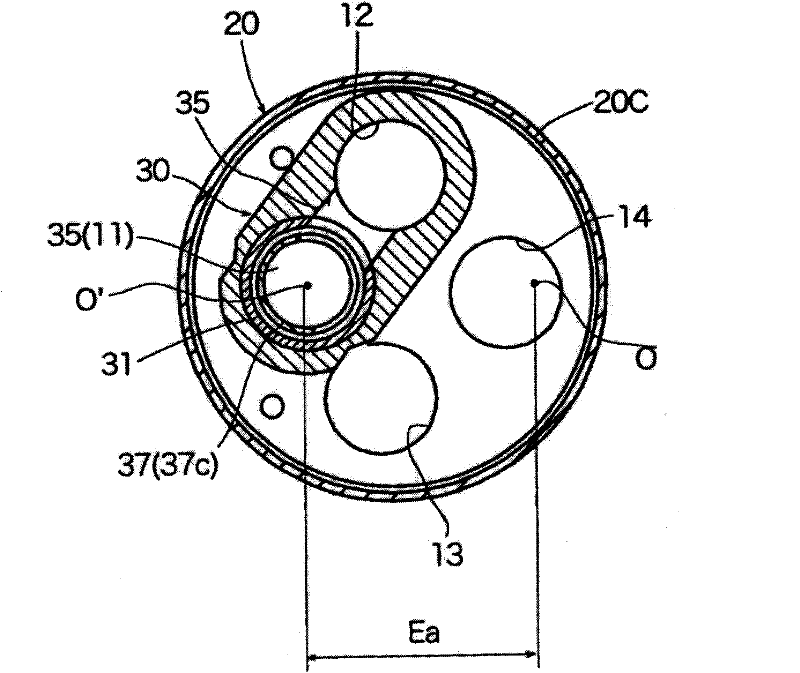

[0066] figure 1 It is a longitudinal sectional view showing one embodiment of the multi-way switching valve according to the present invention, figure 2 yes figure 1 The top view of the multi-way switching valve shown, image 3 From figure 1 The cross-sectional view viewed in the direction of the Y-Y arrow. In each figure, with the aforementioned Figure 4 , Figure 5 The parts corresponding to the parts of the multi-way switching valve 10' shown in the figure are marked with the same symbols, and the description thereof will be omitted.

[0067] The multi-way switching valve 10 of figure example, and Figure 4 , Figure 5 The multi-way switching valve shown in is the same, it has a high-pressure fluid inlet port 11, a first fluid inlet and outlet port 12, a second fluid inlet and outlet port 13, and a low-pressure flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com