Electronic expansion valve

A technology for electronic expansion valves and rotors, applied in valve details, valve devices, valve operation/release devices, etc., can solve problems such as stuck, increase the difficulty of parts assembly, increase product costs, etc., to achieve the reduction of longitudinal length, manufacturing Effects of low cost and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

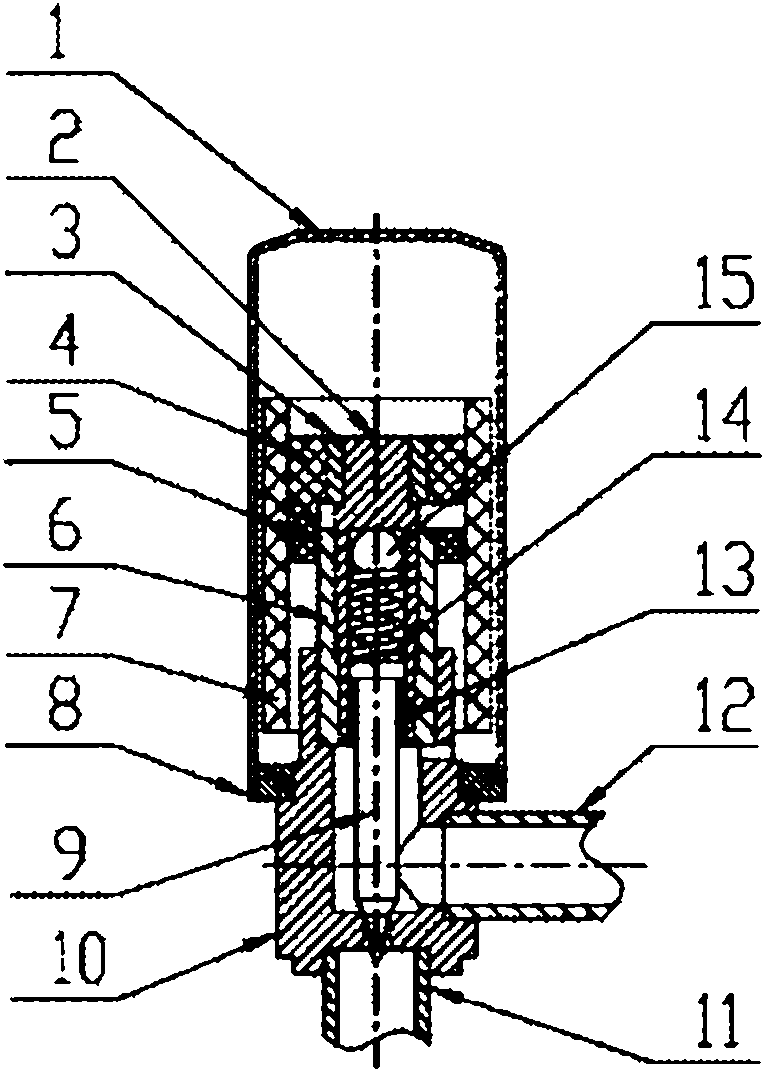

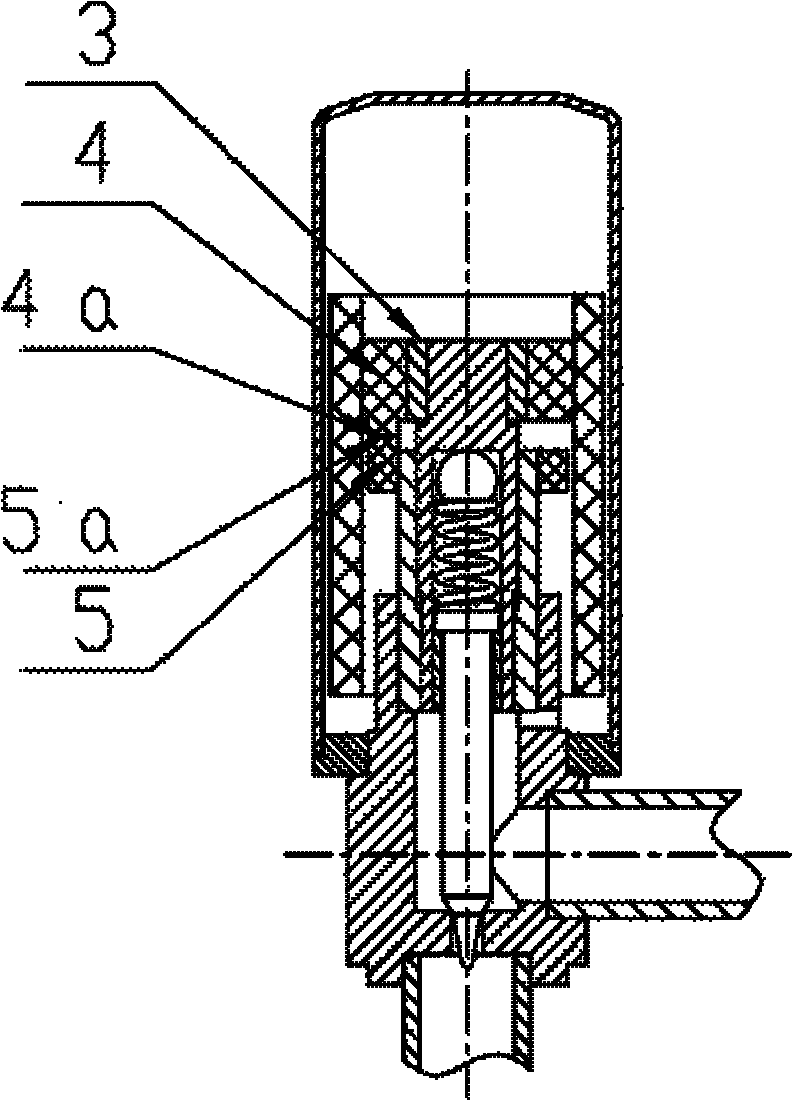

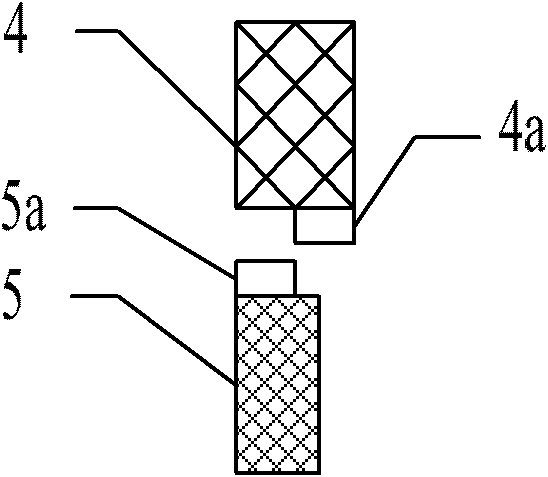

[0018] Such as figure 1 As shown, an electronic expansion valve mainly includes a sleeve 1, a screw sleeve 6, connecting pipes 11 and 12, a valve body 10, and a rotor composed of a multi-pole magnetic ring 7 inside the sleeve 1, bolts 2, and a valve needle 9. Such as figure 2 As shown, the bolt collar 3 and the upper positioning block 4 made of resin material are formed by integral injection molding and fixed connection, and at the same time, a block-shaped protrusion 4a with a position-limiting effect is formed under the upper positioning block 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com