Method for improving using value of tobacco leaf raw material through cigarette processing

A use value and cigarette technology, applied in the field of shredded tobacco processing and cigarette formula, can solve problems such as inaccurate positioning of tobacco leaf functions, insufficient consideration of the influence of tobacco leaf shredded style and quality changes on cigarette products, and unreasonable conditions, etc., to achieve reduction Cigarette formula cost, effect of improving product sensory quality and broadening the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] There are 13 grades of tobacco leaves in the formula tobacco leaves of a domestic three-category cigarette, which are divided into main material tobacco leaf modules (6 grades of tobacco leaves) and auxiliary tobacco leaf modules (7 grades of tobacco leaves). The processing method is that the main material and auxiliary material tobacco leaf modules are loosely rehydrated and fed, and then stored in different leaf storage cabinets. After the main material and auxiliary material modules are cut separately, the main material module tobacco shreds are drum-dried (drum wall temperature 140°C, drying time 6.5 minutes), the auxiliary material module shredded tobacco is air-dried (hot air temperature is 250°C, drying time 10s), the dried main material and auxiliary material module shredded tobacco are mixed and flavored, rolled and packaged into cigarette products.

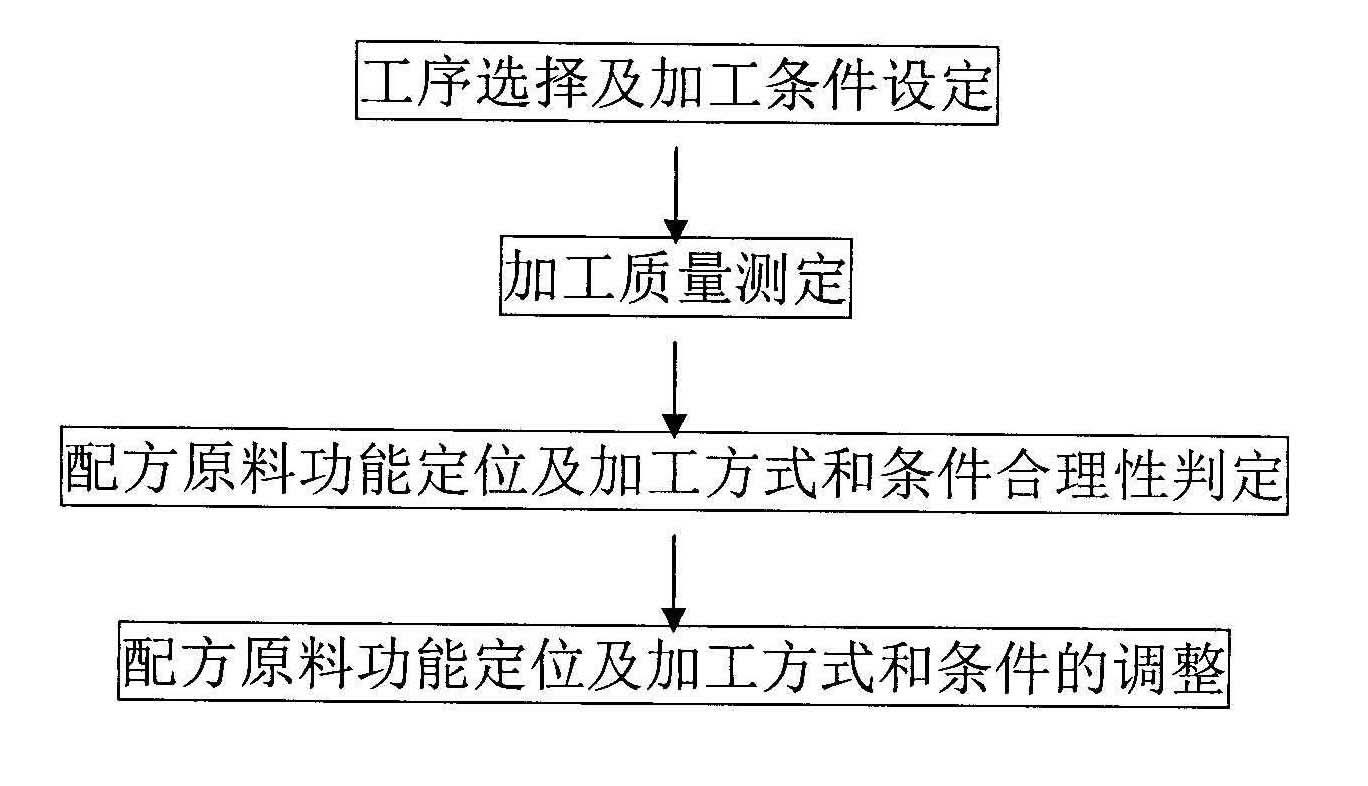

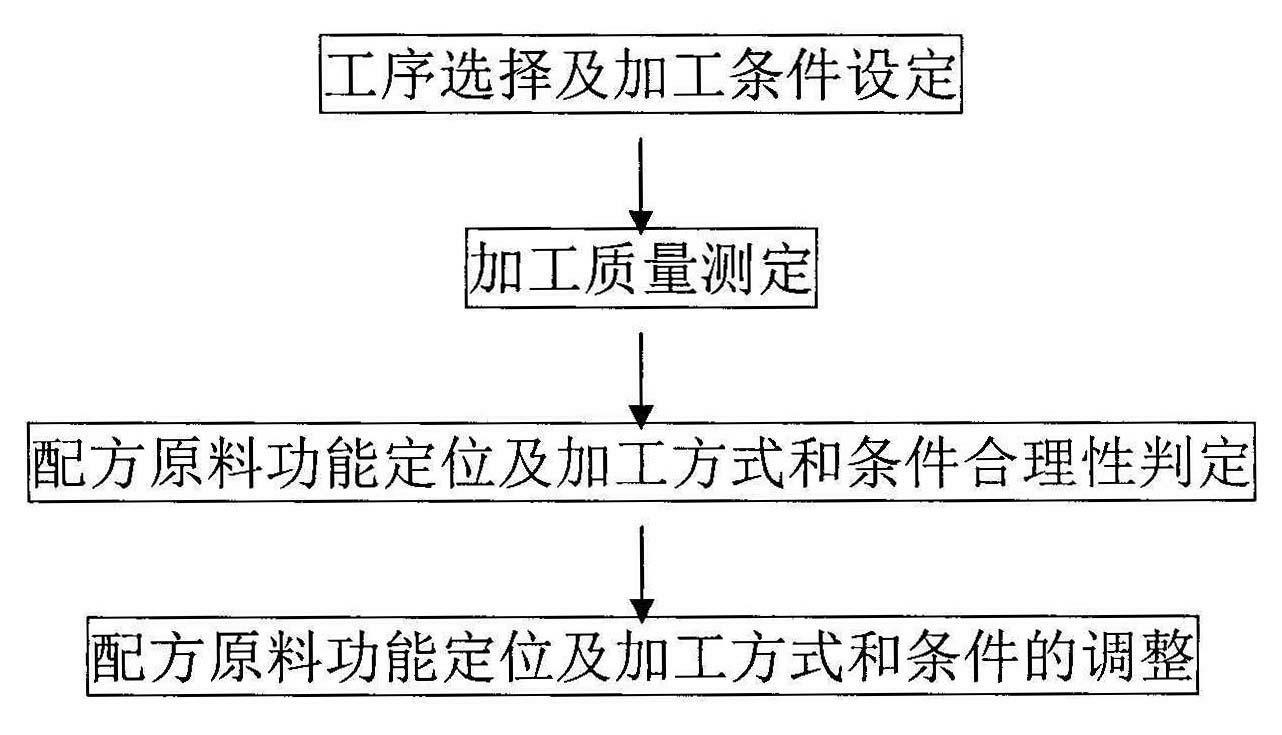

[0035] 1. Drying selection and processing condition setting: select the drum drying and airflow drying processes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com