Construction method of deep foundation pit bracing system

A deep foundation pit support and construction method technology, which is applied in the direction of foundation structure engineering, excavation, sheet pile walls, etc., can solve the problems of low tensile strength, uneven force, and difficult to detect, and achieve short construction period and low impact. The effect of good strength and increased safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The following description is only exemplary and does not limit the protection scope of the present invention.

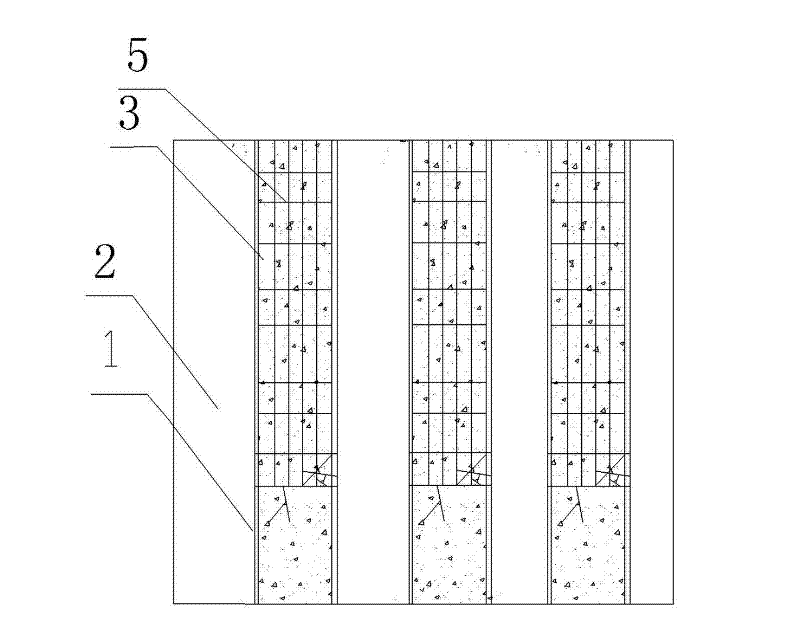

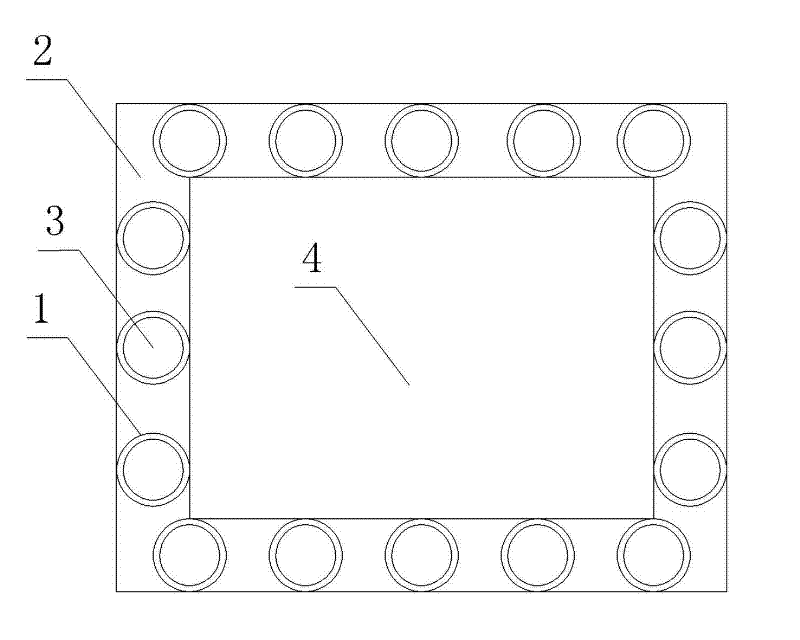

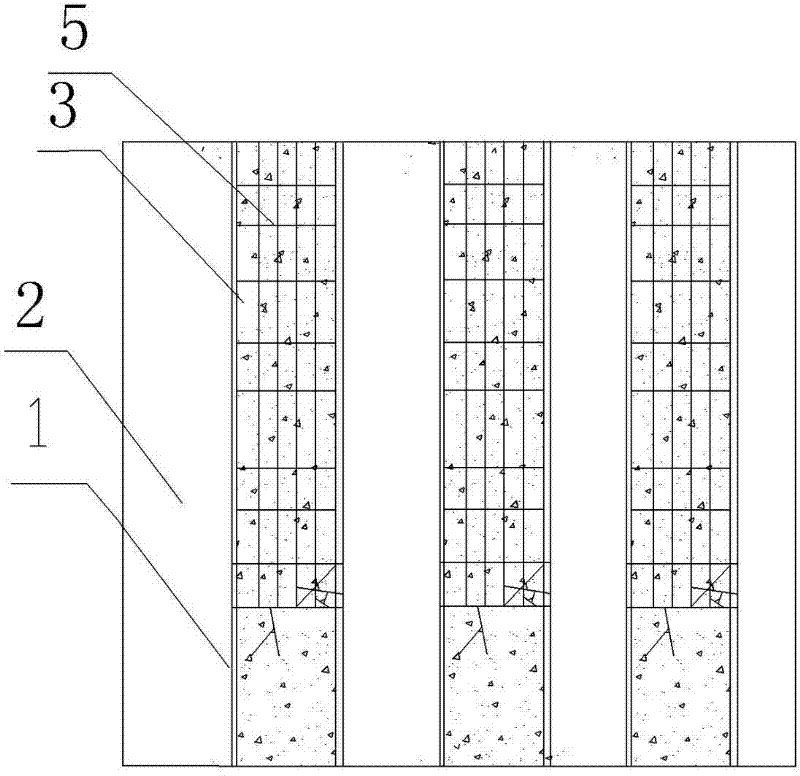

[0029] Reference attached figure 1 , 2 , a deep foundation pit support system, including a curtain 2 on the periphery of the deep foundation pit 4, and a concrete filled steel pipe pile 3 is constructed in the curtain 2, and a steel cage 5 can be provided inside the concrete filled steel pipe pile 3.

[0030] Considering the stress, the steel pipe pile 3 is a round pipe or a square pipe. Of course, those skilled in the art can imagine that the shape of the round pipe of the steel pipe pile 3 can be other shapes.

[0031] A construction method for a deep foundation pit support system, comprising the following steps:

[0032] 1) Drilling with a three-axis drilling rig, drilling into three connected unit grooves at a time, dril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com