Optical laminated body, polarizer, display device and manufacturing method of optical laminated body

A technology of optical laminates and optical functional layers, applied in chemical instruments and methods, optics, optical components, etc., can solve the problems of reduced contrast, whitening of images displayed in black, etc., and achieves the effect of excellent manufacturing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

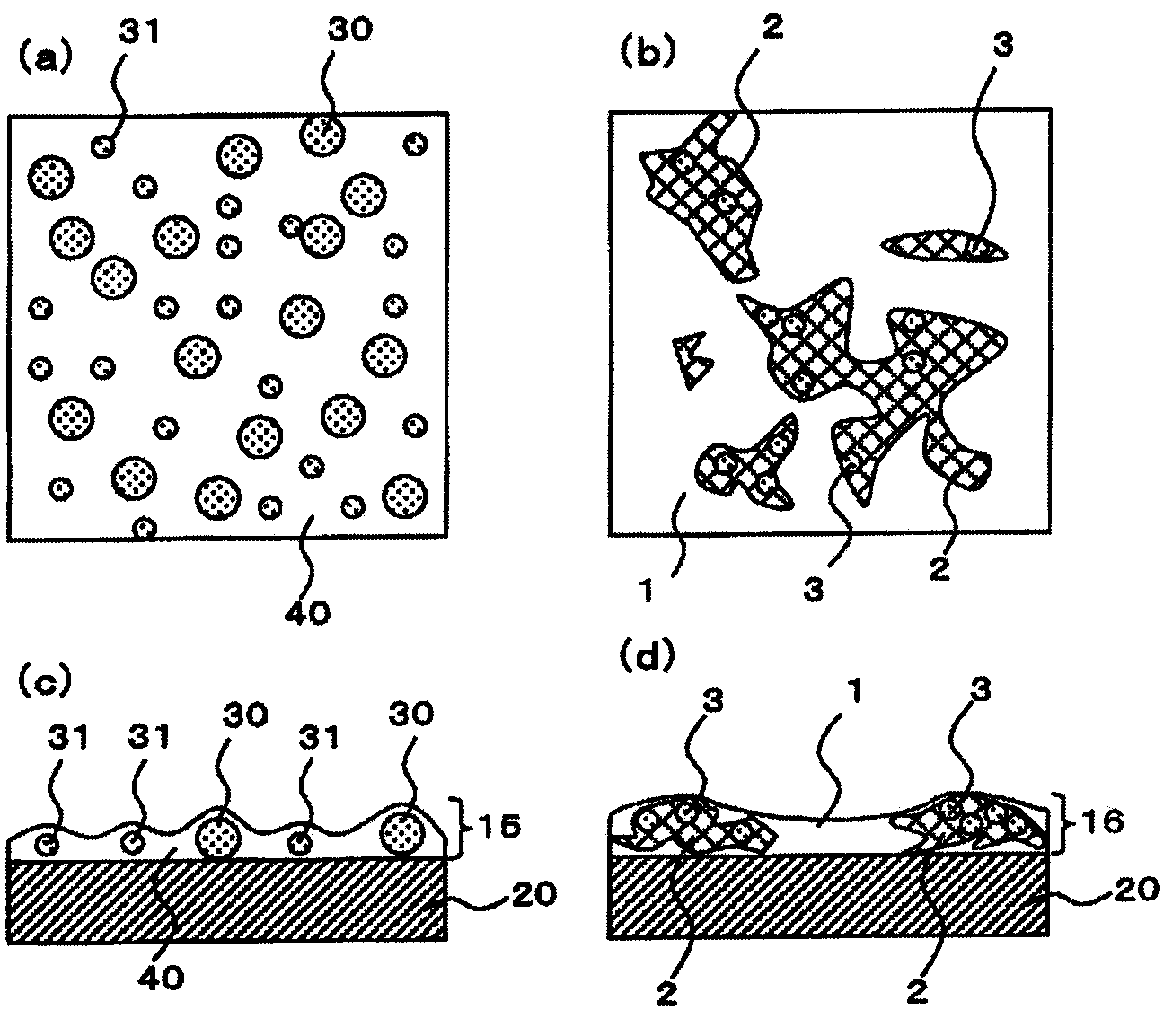

Method used

Image

Examples

manufacture example 1

[0163] (manufacture of production example 1 synthetic montmorillonite)

[0164] Add 4L of water to a 10L beaker, and dissolve No. 3 water glass (SiO 2 28%, Na 2 (09%, molar ratio 3.22) 860g, add 95% sulfuric acid 162g in one go and stir, obtain silicate solution. Next, dissolve MgCl in 1 L of water 2 ·6H 2 O primary reagent (purity 98%) 560g, it is added in the aforementioned silicic acid solution to prepare homogeneous mixed solution. This was dropped into 3.6 L of 2N-NaOH solution over 5 minutes and stirred. Immediately filter the obtained reaction precipitate with a cross-flow (Cross flow) filtration system [Cross flow filter (ceramic membrane filter: pore size 2 μm, tubular type, filtration area 400 cm 2 ), pressurization: 2kg / cm 2 , Filter cloth: Tetoron 1310] After filtering and fully washing, add 200ml of water and Li(OH)·H 2 O 14.5 g of the resulting solution was made into a slurry. Move it into the autoclave, at 41kg / cm 2 , 250°C to make it hydrothermally rea...

manufacture example 2

[0165] (Production Example 2 Production of Synthetic Smectite-Based Layered Organoclay A)

[0166]20 g of the synthetic montmorillonite synthesized in Production Example 1 was dispersed in 1000 ml of tap water to form a suspension. Add 500 ml of an aqueous solution of a quaternary ammonium salt (98% containing product) of the following formula (II) that is equivalent to 1.00 times the cation exchange capacity of the synthetic montmorillonite to the aforementioned synthetic montmorillonite suspension, and stir This was allowed to react at room temperature for 2 hours. The resultant is separated into solid and liquid, washed, and dried after removing by-product salts to obtain the synthetic montmorillonite-based layered organoclay A.

[0167]

Embodiment 1

[0169] The prescribed mixture as described in Table 1 containing the aforementioned layered organoclay A was stirred with a disperser for 30 minutes, and the coating material for forming an optical functional layer thus obtained was applied by roll coating (line speed: 20 m / min). On one side of a TAC (manufactured by Fuji Film Co., Ltd.; TD60UL) transparent substrate with a film thickness of 60 μm and a total light transmittance of 92%, pre-dry at 30 to 50°C for 20 seconds, and then dry at 100°C for 1 The coating film was cured by ultraviolet irradiation (lamp: concentrated type high-pressure mercury lamp, lamp output power: 120W / cm, number of lamps: 4, irradiation distance: 20cm) in a nitrogen atmosphere (nitrogen replacement) for 1 minute. Thus, the optical laminated body of Example 1 which has an optical function layer with a thickness of 5.9 micrometers was obtained. Here, the SEM results observed from the optical function layer of the obtained optical laminated body are a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com