Multi-gradient superfine compound filter element and manufacturing method thereof

A composite filter element and filter element technology, applied in the field of filtration, can solve the problems of long supply time, short service life, high price, etc., and achieve the effect of good filtration accuracy and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

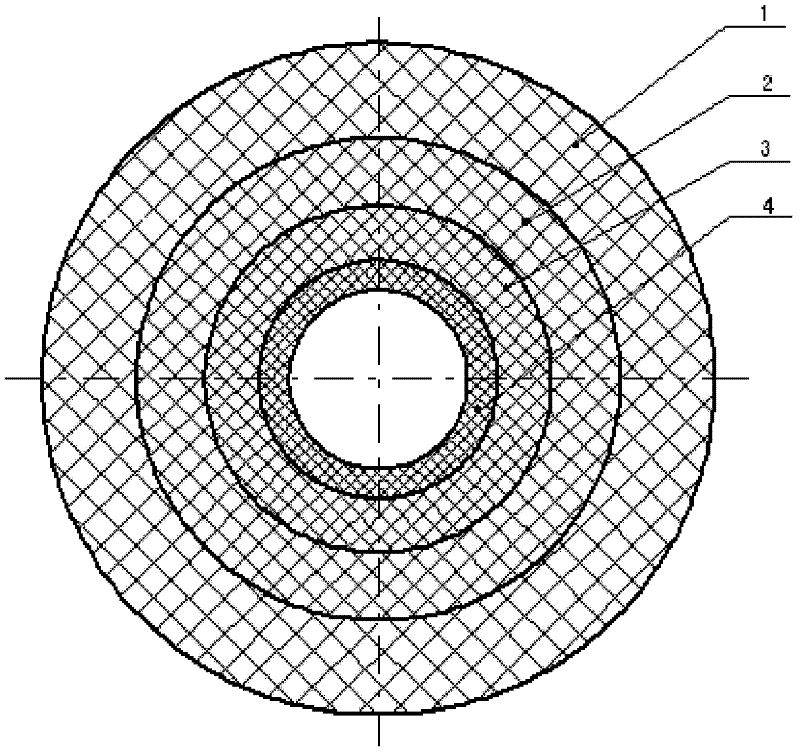

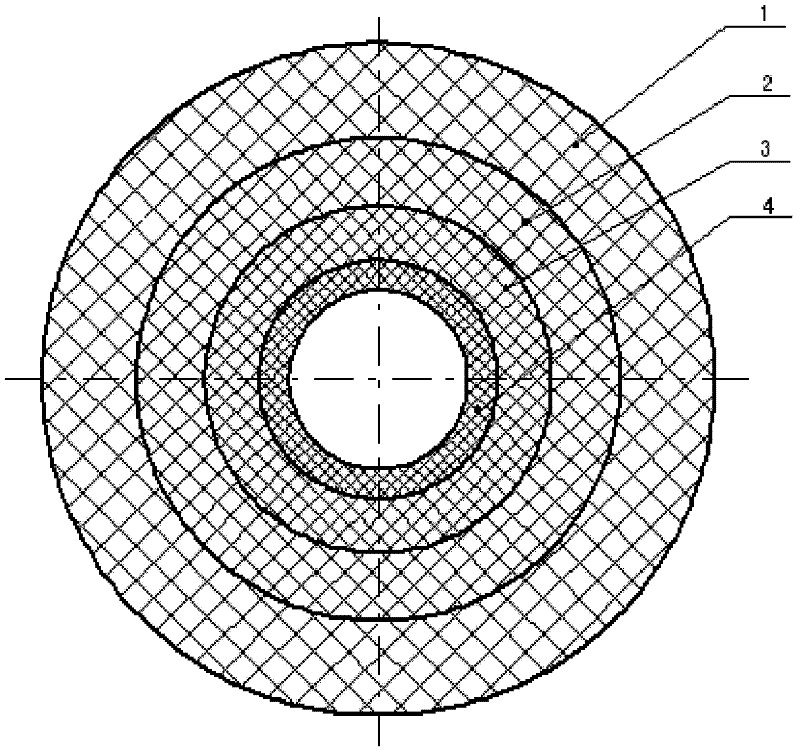

[0020] A multi-gradient ultra-fine composite filter element is composed of two layers of inner cores 3 and 4 and two layers of outer cores 1 and 2 coaxially.

[0021] The outer core has at least one layer, the inner core has at least one layer, and after the inner core and the outer core are combined, there are at least three layers. In this embodiment, both the outer core and the inner core have two layers.

[0022] The filtering pore diameters from the outermost outer core to the innermost inner core present a decreasing gradient.

[0023] In this embodiment, the filter aperture of the outer core is 1-30 microns; the filter aperture of the inner core is 0.3-10 microns.

[0024] A multi-gradient ultra-fine co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com