Feedback magnetic chip suction device

A feedback and magnetic technology, applied in the field of mechanical processing, can solve the problems of inability to bend, no desquamation, no automatic desquamation function, etc., to avoid mutual interference and the effect of magnetic force is not affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A specific embodiment of a feedback type magnetic chip suction device of the present invention is given below with reference to the accompanying drawings.

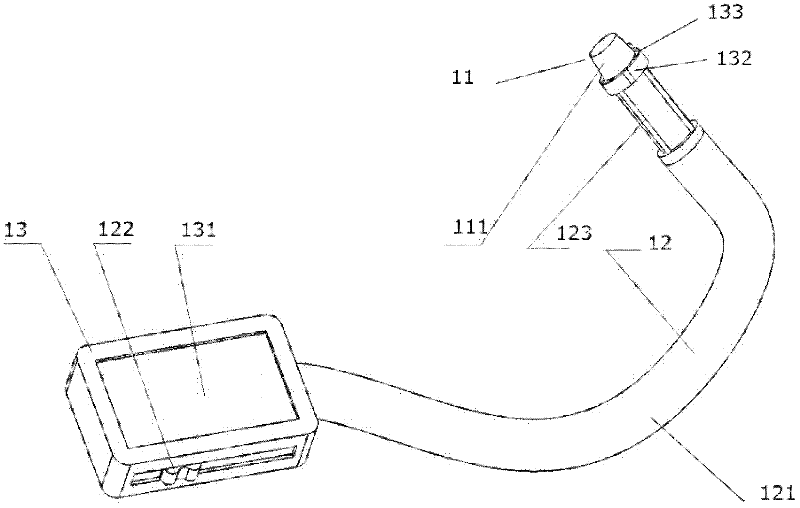

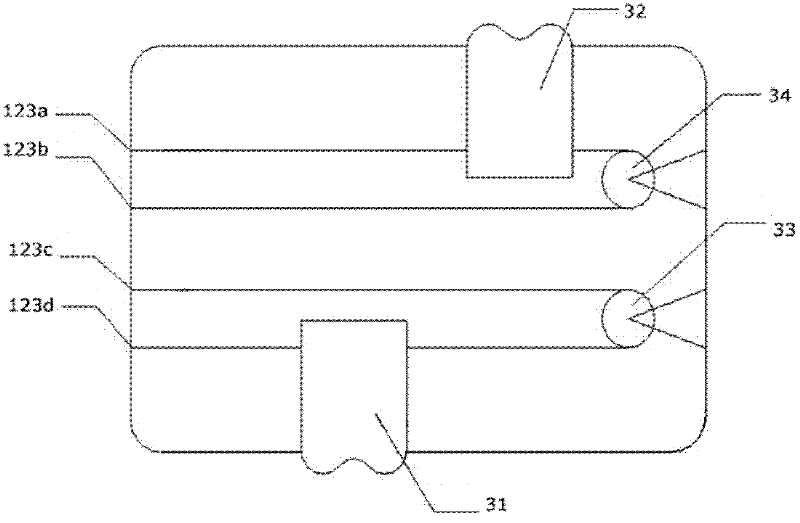

[0025] Please refer to figure 1 , which is a structural schematic diagram of the feedback magnetic chip suction device of the present invention. Such as figure 1 As shown, the present invention includes an adsorption body 11, which is connected to a linkage system 12 and a feedback system 13 in sequence.

[0026] The feedback system 13 includes: a screen 131, a power supply (not shown), an LED light 132 and a camera 133, the LED light 132 and the camera 133 are arranged on the adsorption body 11, the screen 131 and the linkage system 12 The first terminal is connected, the power supply is connected to the screen 131, and the power supply is used to supply power for the feedback system 13;

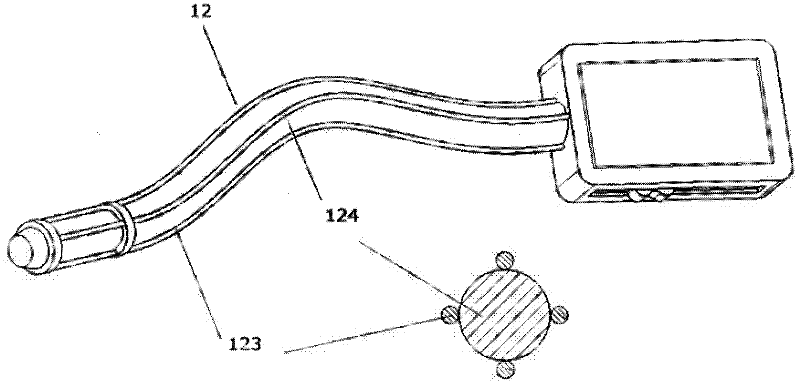

[0027] The outside of the linkage system 12 is a metal hose 121, and also includes a slider 122, the slider 122 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com