Abnormal shaping drum

A technology for forming drums and special shapes, applied in the field of rubber machinery, can solve the problems of unrealized tire pressing rollers, affecting product quality, and large gaps between tiles and tiles, and achieves the effects of improving quality, reducing labor intensity and narrowing gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

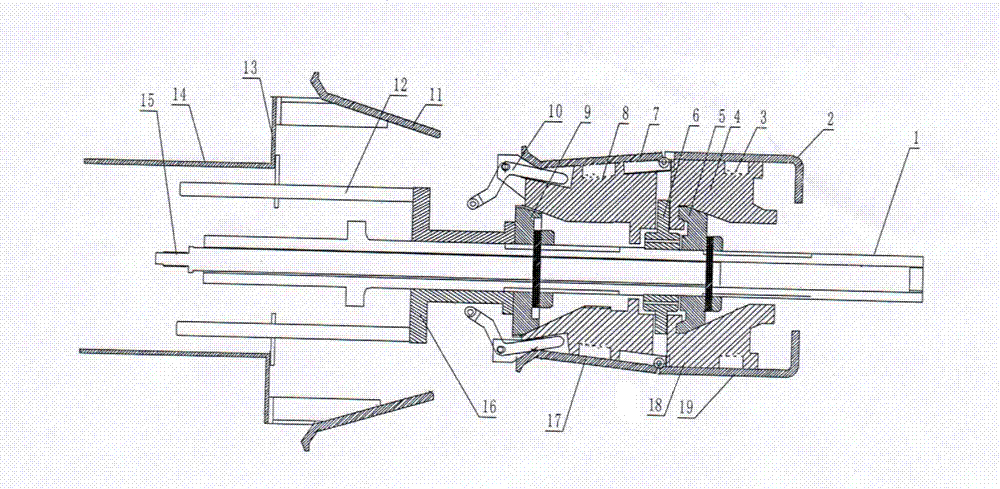

[0015] The special-shaped forming drum device of the present invention is realized in this way: the pull rod (15) pushes the outer sliding seat (5) and the inner sliding seat (9) on the main shaft (1) to the right under the drive of the cylinder. The position of the starting point of the slope of the drum tile seat is different, and the inclination is different, so that the narrow drum tile seat (4) first moves radially outward along the pin shaft on the positioning seat (6), and the wide drum tile seat (18) then also moves outward , at the same time, the push plate (13) moves to the right and presses the movable connecting rod (12) to lift the side of the narrow special-shaped tile (7) and the wide special-shaped tile (19) outward, and insert the filling tile (14) on the tile gap component into the wide special-shaped tile (22) and the narrow special-shaped tile (5), so that there is basically no gap between the tiles when the special-shaped drum is inflated. Under the action...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com