Elastic tensioning device for growth of diamond film electrode

A diamond film and tensioning device technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of poor deposition uniformity, inaccurate adjustment, complex structure, etc., to achieve good cooling effect, electrode Simple structure and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

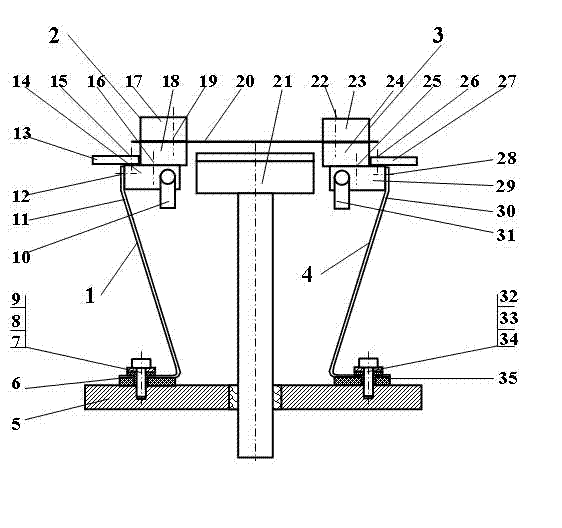

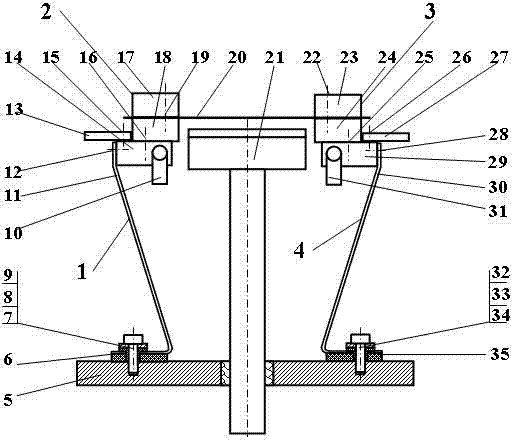

[0026] Such as figure 1 shown.

[0027] An elastic tensioning device for a diamond film growth electrode, which is mainly composed of a left elastic support 1, a left molybdenum electrode 2, a right molybdenum electrode 3, a right elastic support 4, and a heating wire 20 (also called a filament array), etc. Such as figure 1 As shown, the hot wire 20 and the left molybdenum electrode 2 and the right molybdenum electrode 3 connected to it constitute the electrode of the present invention. The left elastic support 1 is formed by stacking a plurality of left spring pieces 11. Screw 7, insulating sleeve 8, and gasket 9 are connected with base plate 5; right elastic bracket 4 has the same structure as left elastic bracket 1, and it is formed by stacking multiple right spring pieces 30, and right spring piece 30 passes through insulating pad 35 , screw 32, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com