Clothes drying machine

A technology for drying machines and drying racks, which is applied in household dryers, other drying devices, washing devices, etc., can solve the problems of difficult body strength and body stability, overheating of support columns, and difficult design breakthroughs, etc. Improved strength and safety performance, easy switch operation, and the effect of visual observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

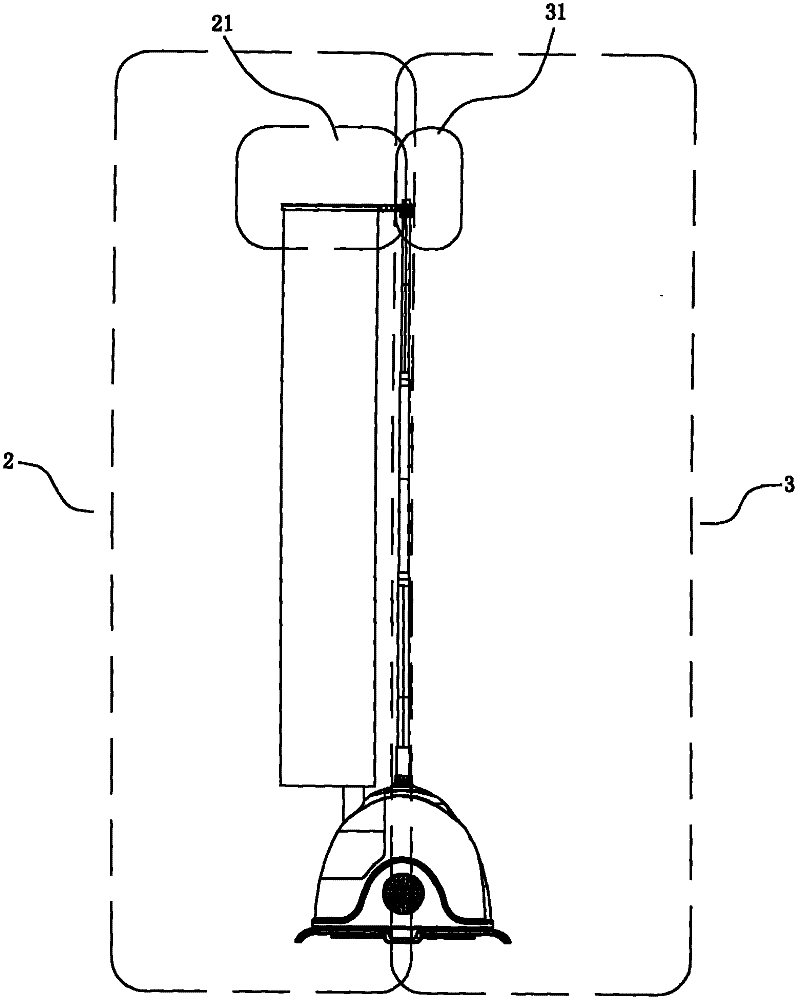

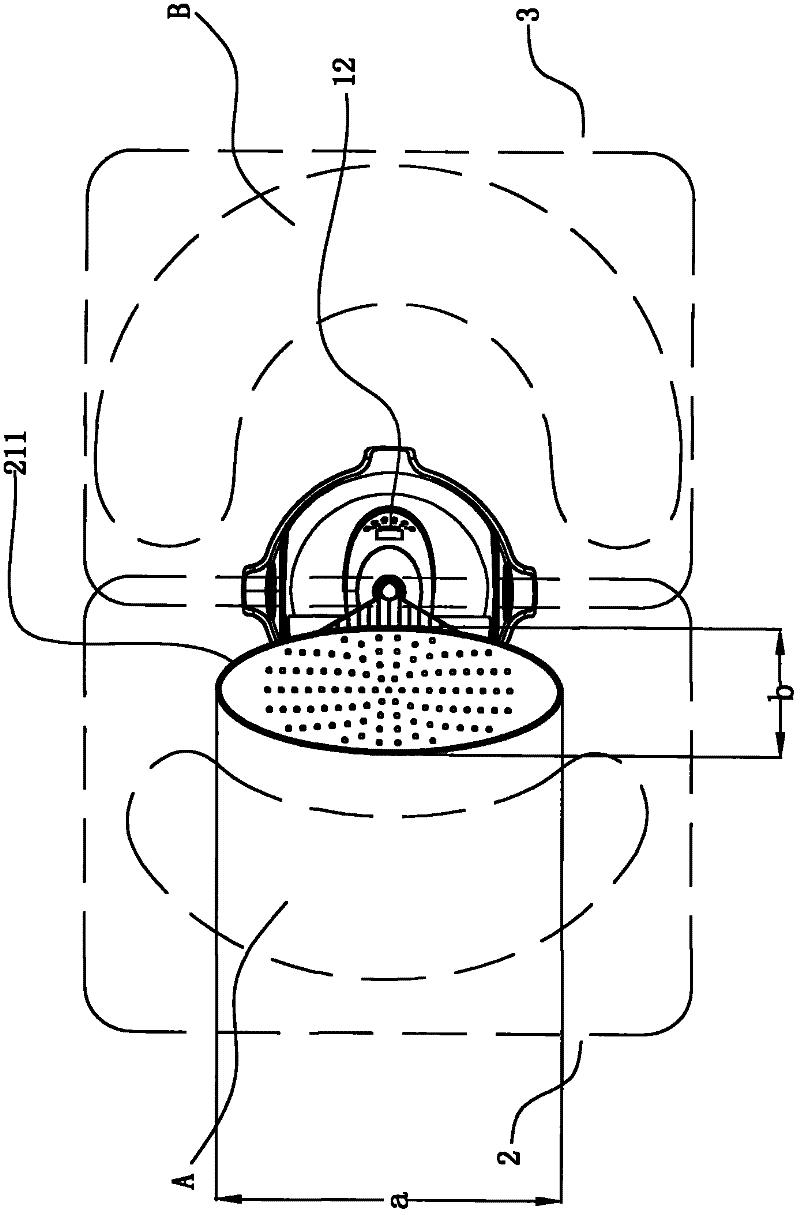

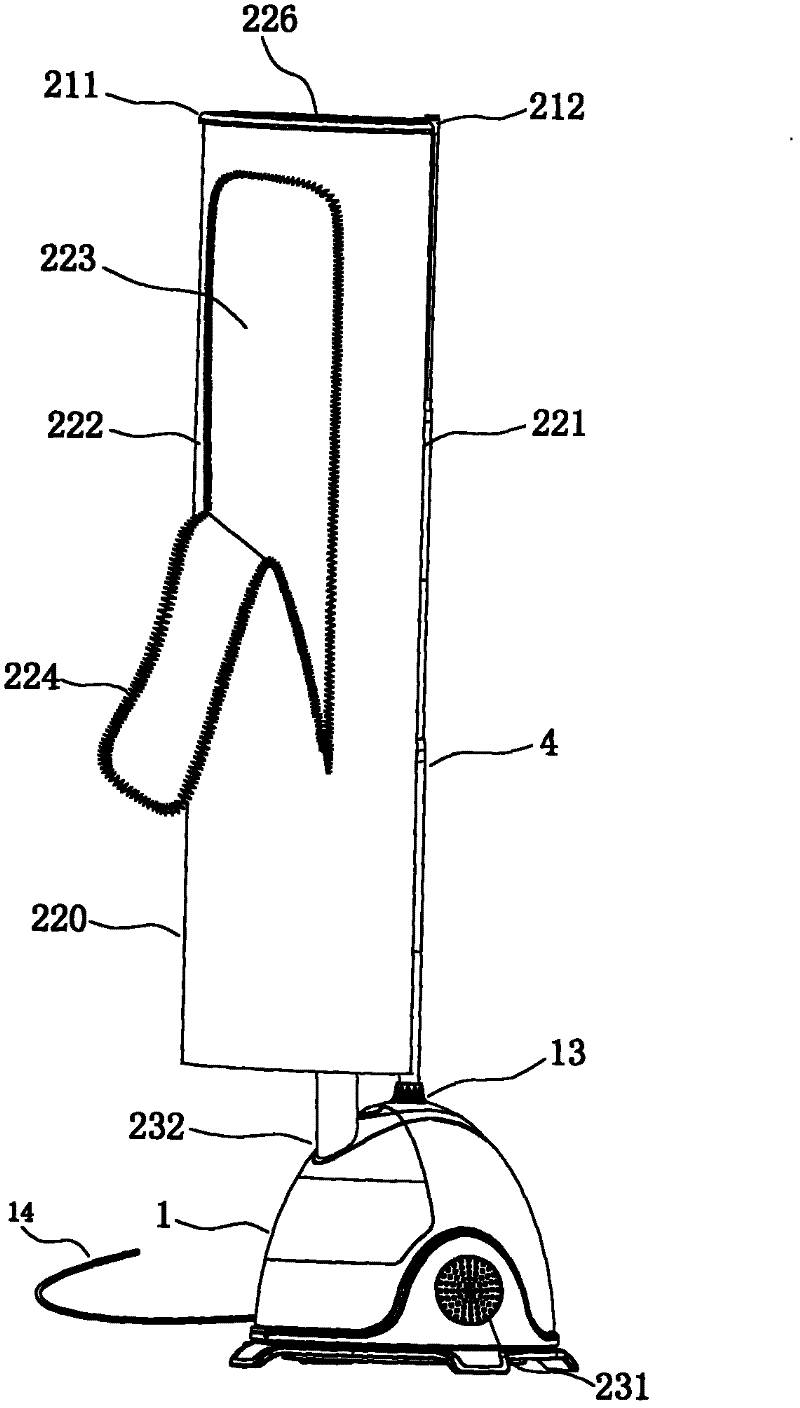

[0054] as attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown is an illustration of a preferred embodiment of the present invention. This high-efficiency dryer includes a support body 1 , a column 4 whose lower end is fixed on the support body 1 , and a cover 22 of a drying unit 2 located on one side of the column 4 , and a space unit 3 is formed on the other side of the column 4 . Wherein the drying unit 2 comprises a drying rack part 21 located on the left side of the column 4 and fixed on the upper end 41 of the column, a cover body 22 whose upper end hangs on the drying rack part 21 and naturally hangs down along the left side of the column 4, and is arranged inside the support body 1 The heating element 23. The shell of the support body 1 corresponding to the side of the space unit 3 is provided with a control panel 12 for controlling and operating the dryer, a power cord 14 for connecting the dryer to an external power source, an air inlet 231, an...

Embodiment 2

[0059] as attached Figure 6 , Figure 7 as well as Figure 8As shown, the difference from Embodiment 1 is that the heating component 23 in this embodiment is not inside the support body 1 , but is fixed on the upper end 41 of the column and on the side of the drying unit 2 . The upper end of the cover 22 is sleeved on the outer periphery of the supporting top frame 211, and the supporting top frame 211 is fixed in the groove 230 on the lower outside of the heating component 23. The cover 22 extends downward along the supporting top frame 211, and the bottom 220 of the cover is set There is a base plate 25 that expands the cover body bottom 20, and the base plate 25 is fixed on the lower end of the column 4 by side buckles 6, and the base plate 25 is provided with an outflow hole 251 for airflow to flow out. The inside of the housing of the heating component 23 is provided with a partition plate 234, the partition plate 234 divides the housing of the heating component 23 int...

Embodiment 3

[0061] The heating part 23 can also be fixed on any position of the column 4 between the drying frame part 21 and the support body 1, and also realizes the lower heating drying structure or the upper heating drying structure, and the inner space 223 of the cover body 22 Heating and blowing air can be implemented at any position. as attached Figure 9 and Figure 10 As shown, it is a lower heating drying structure. The heating component 23 is fixed on the lower end of the column body of the column 4 between the drying rack component 21 and the support body 1, and the partition plate 234 inside the housing of the heating component 23 separates the internal space of the heating component 23 into upper parts that communicate with each other. The slow air chamber 235 and the lower electrical appliance chamber 236, the electrical appliance chamber 236 has a groove toward the upper gentle air chamber 235, and a fan 238 and a heating element 237 are coaxially fixed on the partition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com