Electrically-charged oil-change device in transformer switch room and application method thereof

A switch room and transformer technology, applied in the direction of transformer/inductor cooling, transformer, variable transformer, etc., can solve the problems of incomplete oil treatment, failure to meet requirements, high cost, etc., to reduce the number of times and maintenance work time , Improve the safety and reliability of power supply, and reduce maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

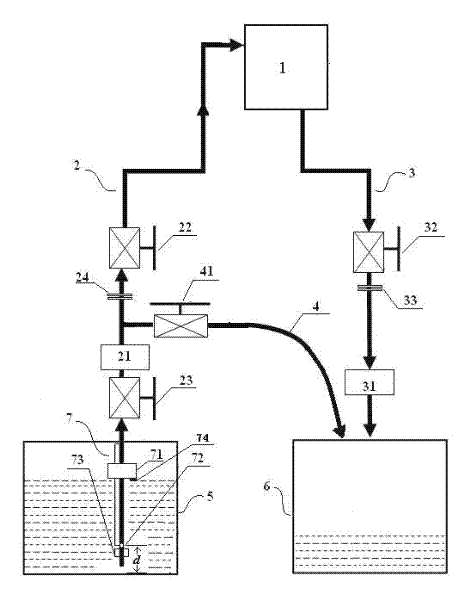

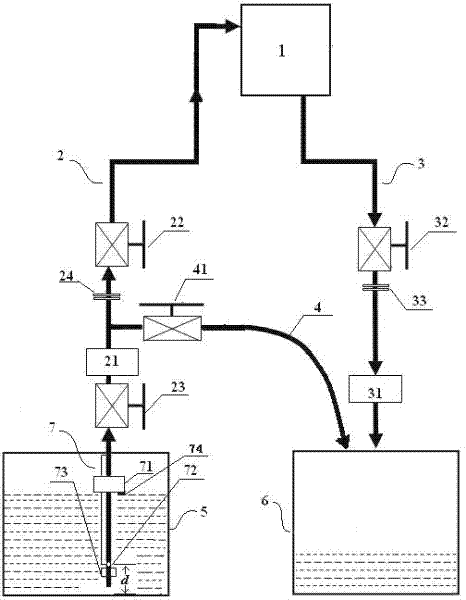

[0022] In order to make the content of the present invention more comprehensible, further description will be made below in conjunction with the accompanying drawings and specific embodiments.

[0023] combine figure 1 It is a specific embodiment of the oil change vehicle of the present invention. The oil change vehicle includes a new oil storage chamber 5, an old oil storage chamber 6, an oil delivery pipeline 2, an oil extraction pipeline 3 and an exhaust pipeline 4, wherein the oil extraction pipeline The outlet of 3 is connected to the old oil storage chamber 6, and the inlet is used to connect to the oil tank 1 of the switch room. The pipeline between the outlet and the inlet is provided with a first oil filter 31 and a first valve 32 in sequence; the inlet of the oil pipeline 2 is connected to the new oil The storage chamber 5, the outlet is used to connect the oil tank 1 in the switch room, the pipelines between the inlet and the outlet are provided with a fourth valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com