Controllable scouring system for cleaning heating surfaces of boiler and method

A heating surface and boiler technology, which is applied in the system field of cleaning the heating surface of the boiler, can solve the problems of mechanical parts wear energy, dead angle of soot cleaning, overfrequency of soot blowing, etc., and achieves small mechanical wear and impact, simple pipeline transformation, and high flow rate. require small effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the components shown in the figures are schematic and not drawn according to specific dimensions, and the specific embodiments are used to illustrate the present invention and not limit the scope of the present invention.

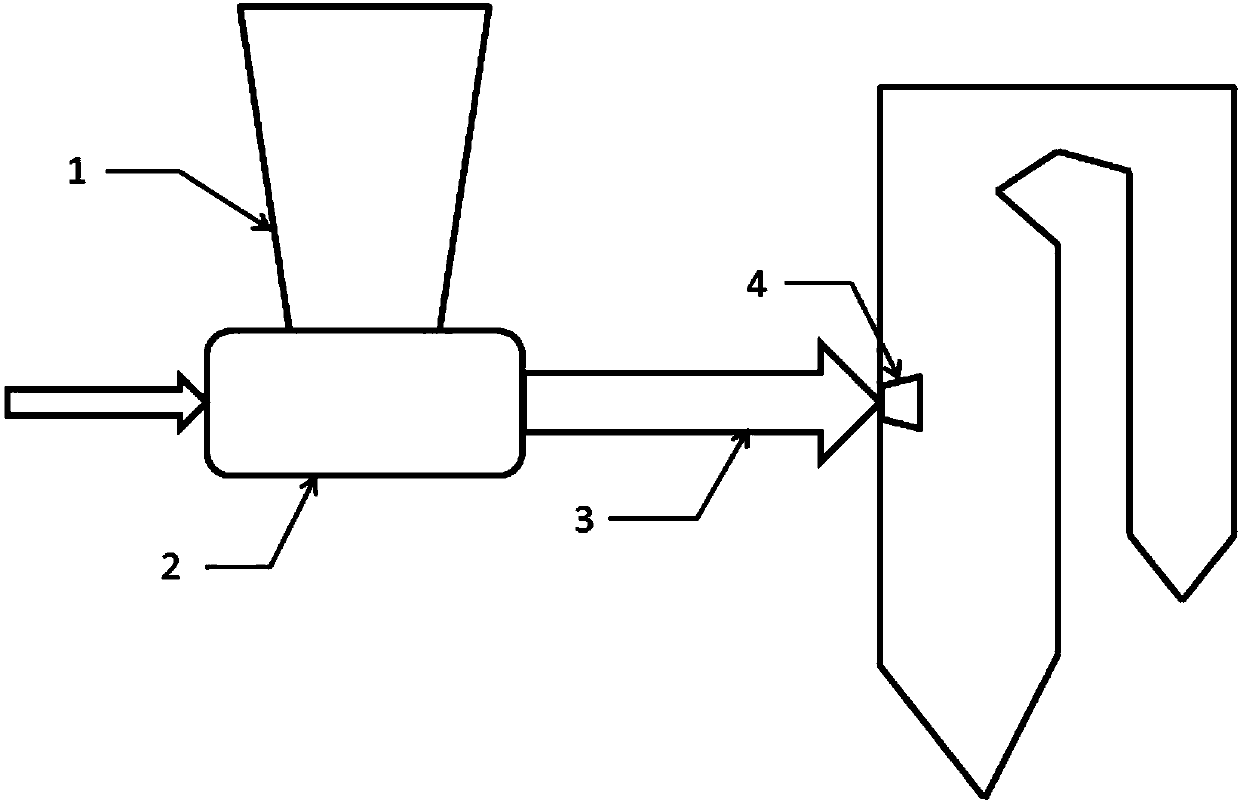

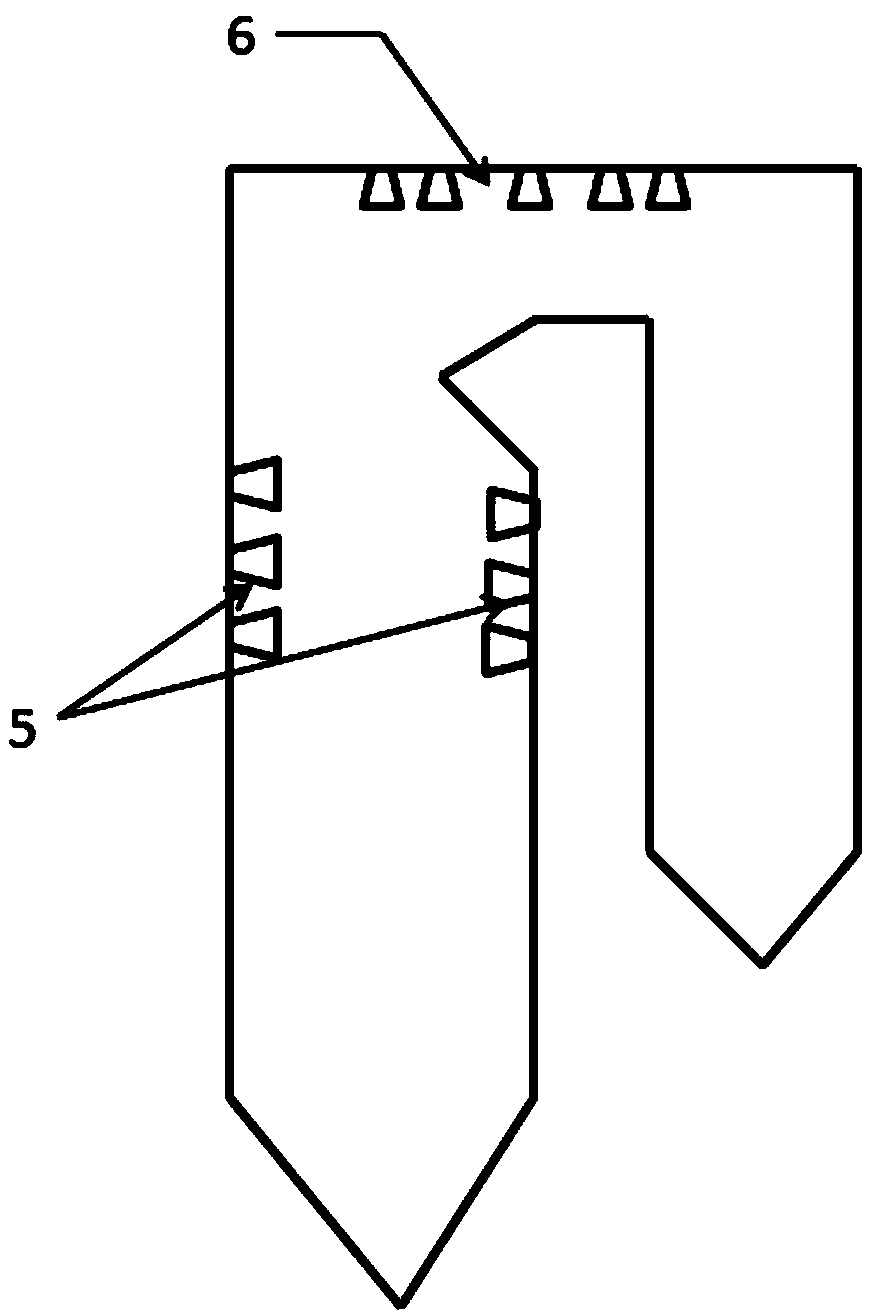

[0019] Such as figure 1 As shown, a controllable erosion system for cleaning the heating surface of the boiler according to the present invention includes several groups of sandblasting ports 4 installed on the boiler furnace wall, and several groups of sandblasting ports 4 connected to the boiler furnace wall. A soot blowing medium delivery pipe 3, and a particle supply system 1 and a gas-particle mixing device 2 connected to the soot blowing medium delivery pipe 3.

[0020] The particle supply system 1 supplies sand particles to the gas-particle mixing device 2, and the flowing gas enters the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com