Method and device for manufacturing structured lining wave, and such lining wave

A corrugated, structured technology that can be used in chemical instruments and methods, transportation and packaging, liquefaction, etc., to solve problems such as increasing metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

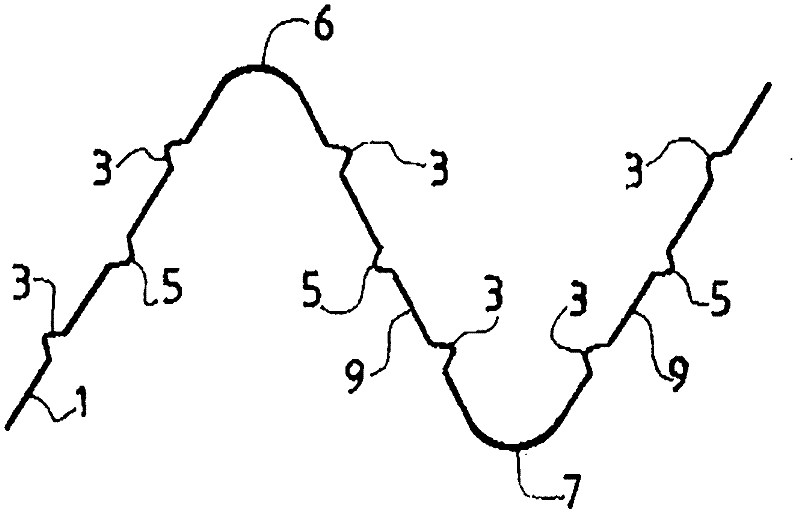

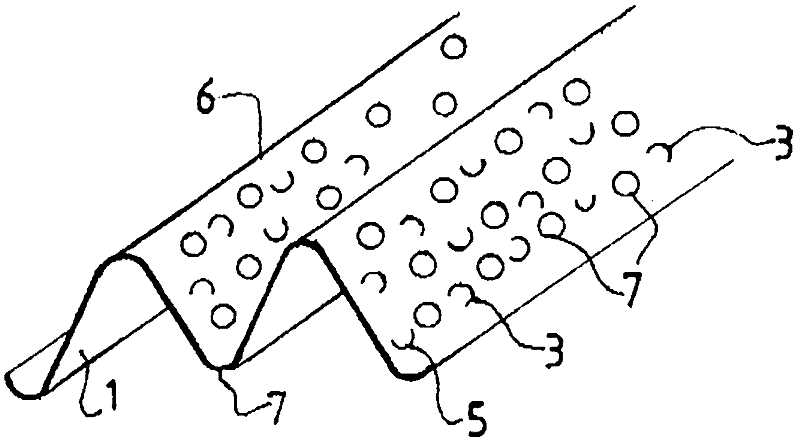

[0031] figure 1 The corrugation (plate) 1 shown in side view is a thin metal plate bent to form regular corrugations. The repeating profile of the corrugation (plate) 1 is zigzag with curved sides 9, with upper 6 and lower 7 peaks with the smallest possible radii.

[0032] The elevations 3 and depressions 5 are formed at least in the slope of the corrugation. The protrusions and depressions are of the same shape so that a protrusion 3 viewed from one side (face) of the strip becomes a depression when viewed from the other side (face) of the strip.

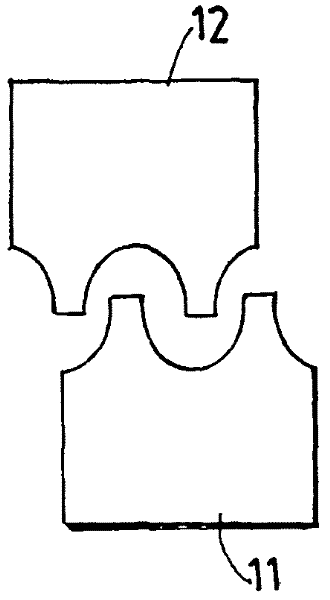

[0033] The corrugated (plate) 1 is made by simple bending and stamping of a thin flat (flat) metal strip with a device A comprising two opposing die blocks, namely a lower die block 11 and an upper die block 12, The lower mold block 11 and the upper mold block 12 are alternately moved towards and away from each other.

[0034] Each mold block has two teeth projecting towards the other mold block, which are indicated by reference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com