Device for crimping element to be crimped on part

A technology of crimping components and connectors, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as immediate shutdown, broken free end of punch, damaged positioning parts, etc., to achieve the effect of eliminating the risk of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

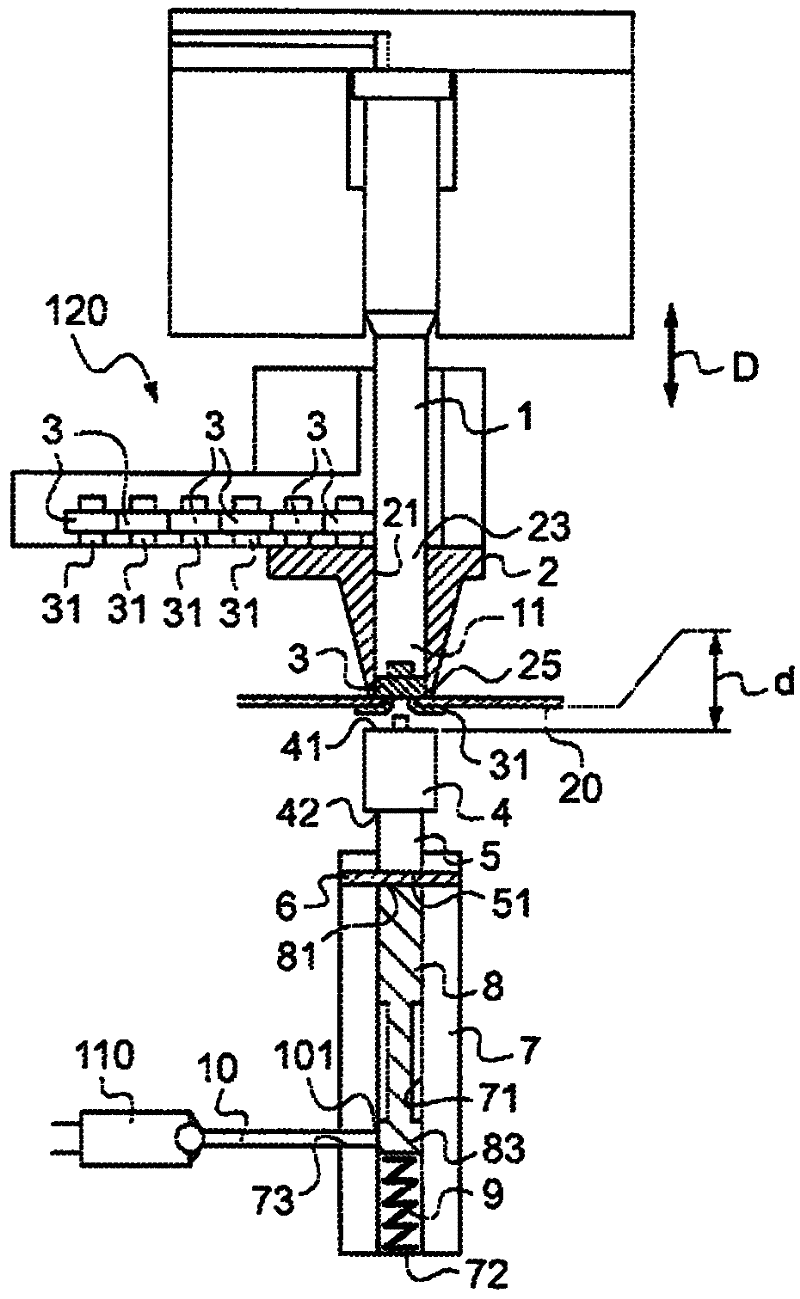

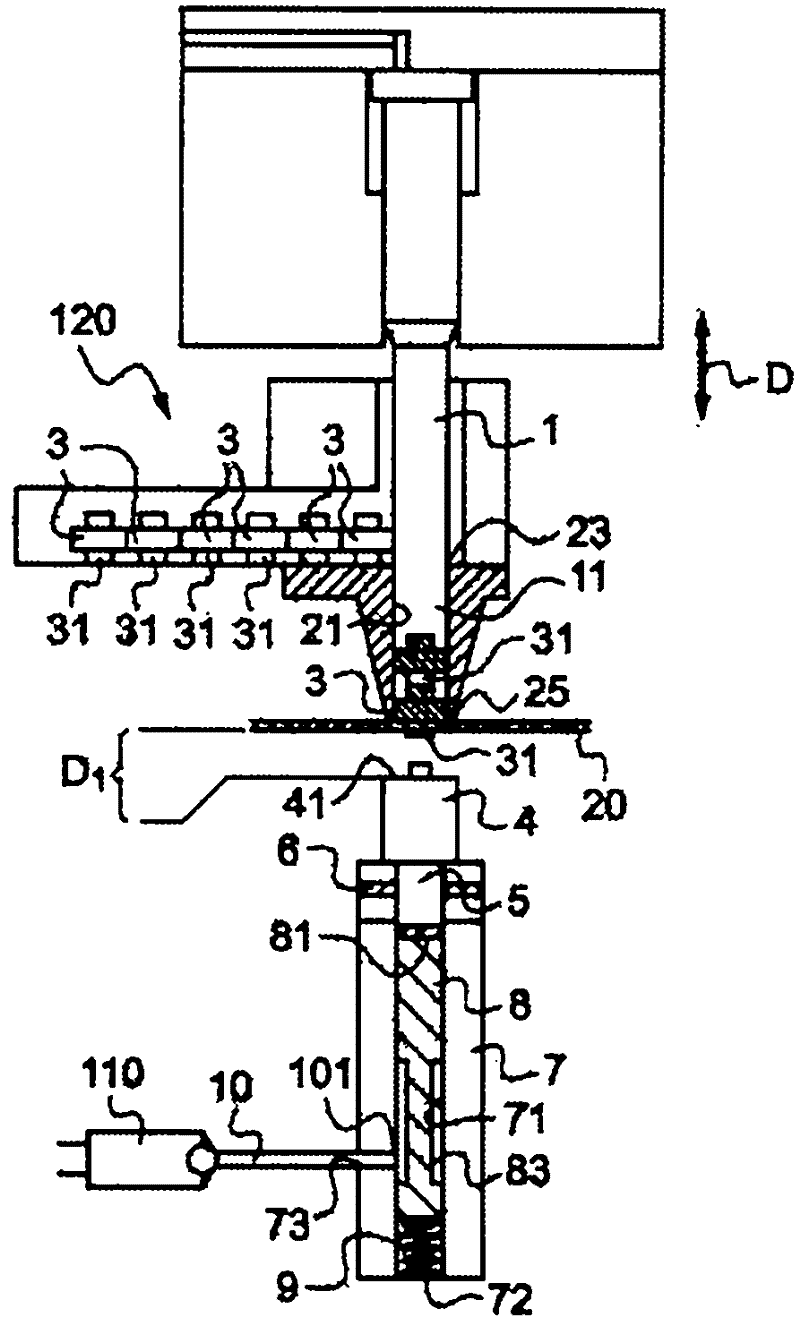

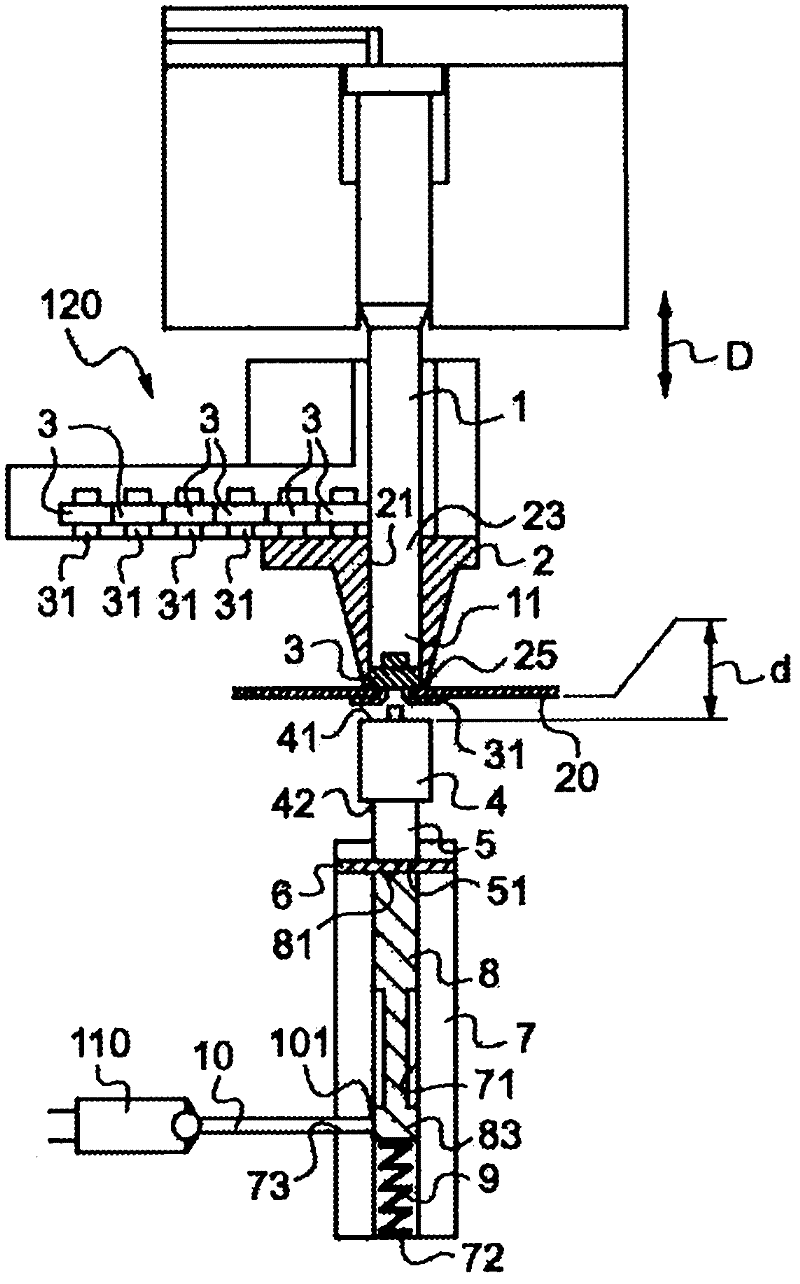

[0023] figure 1 One embodiment of the device of the invention is shown. In the embodiments described here, crimping is performed by deforming a part of the element to be crimped. Obviously, the device of the invention also covers the crimping of an element to be crimped to a part by deforming a part of the part, possibly in combination with the deformation of the element to be crimped.

[0024] The device 1 comprises a punch 1 with a free end 11 . The punch 1 is capable of a translational movement in a direction D, which in this particular example is a vertical direction. The device comprises a positioning element 2 in which a vertical channel 21 is formed, ie a channel parallel to the direction D. Channel 21 has an inlet 23 and an outlet 25 . The positioner 2 is arranged such that the free end 11 of the punch 1 can move in the channel 21 . The punch 1 moves between a raised position, in which the free end 11 of the punch 1 is located above and at a distance from the entr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com