Device for cleaning screen printing mask, screen printing machine, and method for cleaning screen printing mask

A screen printing machine, screen printing technology, applied in screen printing machine, printing machine, rotary printing machine and other directions, can solve the problem of low cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

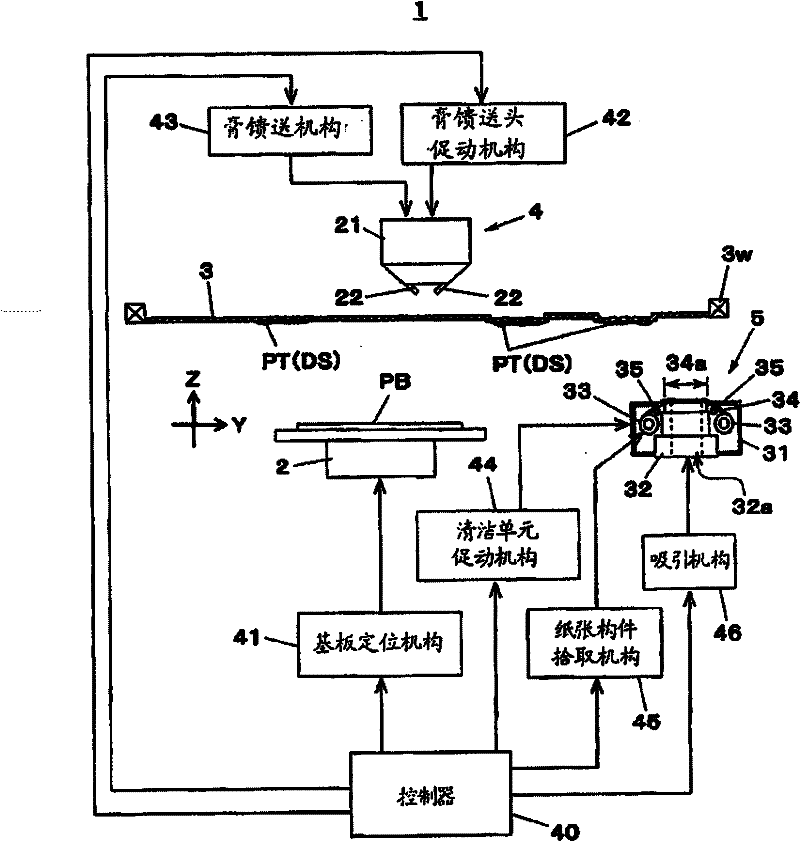

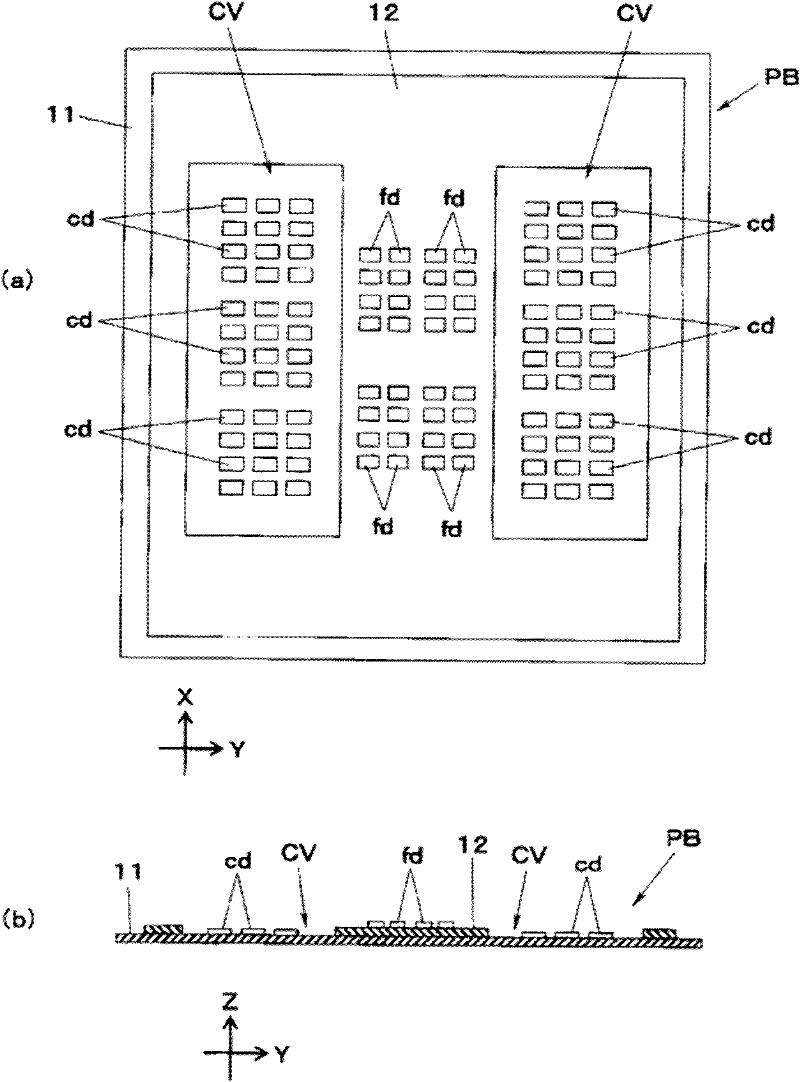

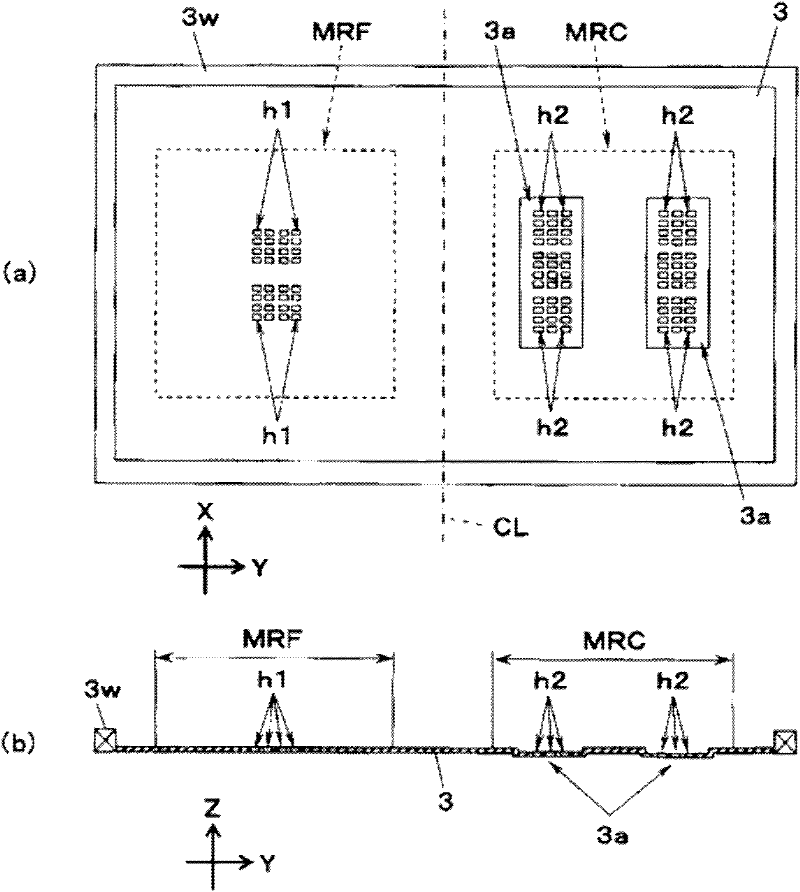

[0038] Embodiments of the present invention are described below with reference to the accompanying drawings. exist figure 1 Among them, the screen printing machine 1 of the embodiment includes: a substrate holding block 2 that holds a substrate PB as a printing object; a screen printing mask (hereinafter referred to as "mask") 3, which is arranged on 2 above the substrate PB held and all appearing as a rectangle; the paste feeding head 4 disposed above the mask 3; and the cleaning unit 5, which contacts from below the bottom surface of the mask 3 and where the screen printing machine 1 has completed the screen Clean the mask 3 after printing. For ease of explanation, the direction of the short side of the mask 3 (perpendicular to figure 1 The direction of the drawing) as the X-axis direction; the direction of the long side of the mask 3 ( figure 1 The horizontal direction of the drawing) as the Y-axis direction; the thickness direction of the mask 3 ( figure 1 The vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com