Panel implanting and positioning device

A positioning device and panel technology, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve problems such as low efficiency, cumbersome movements, and increased production cycle of composite wallboards, and achieve high efficiency and accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

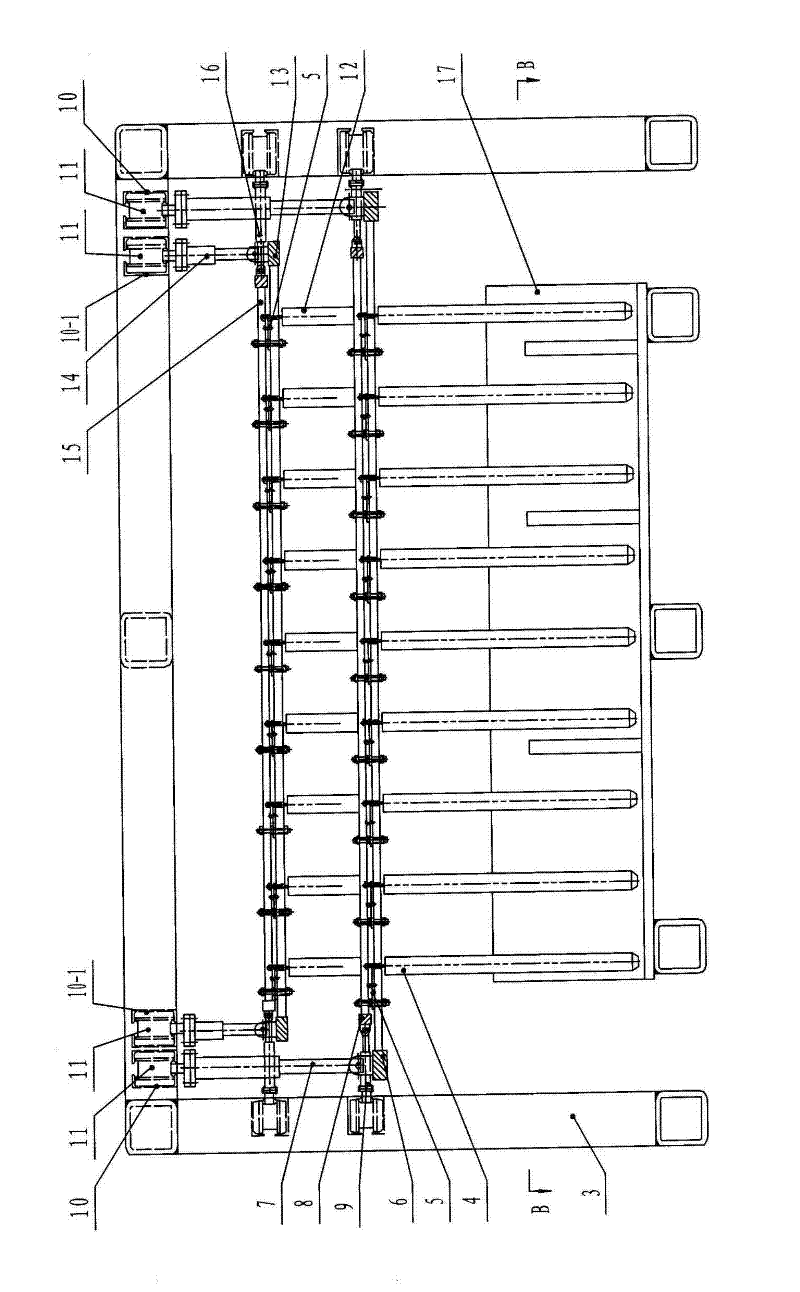

[0033] The present invention will be further described below in conjunction with the embodiments (accompanying drawings), that is, taking six molding cavities as an example:

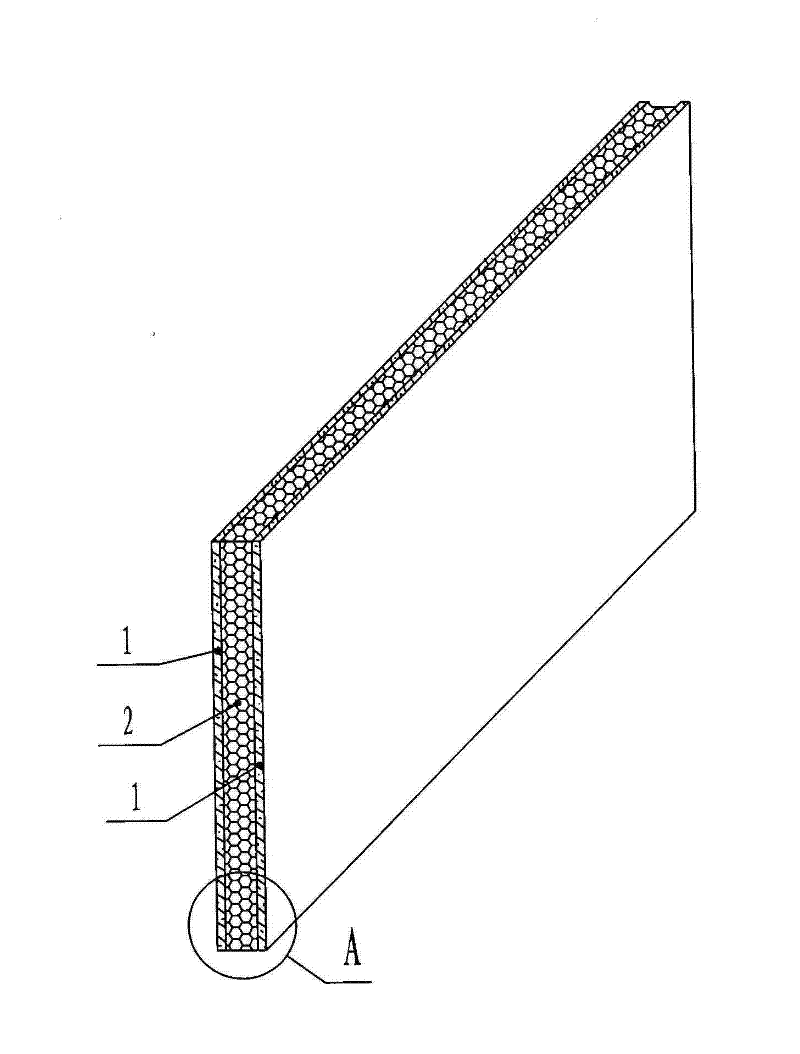

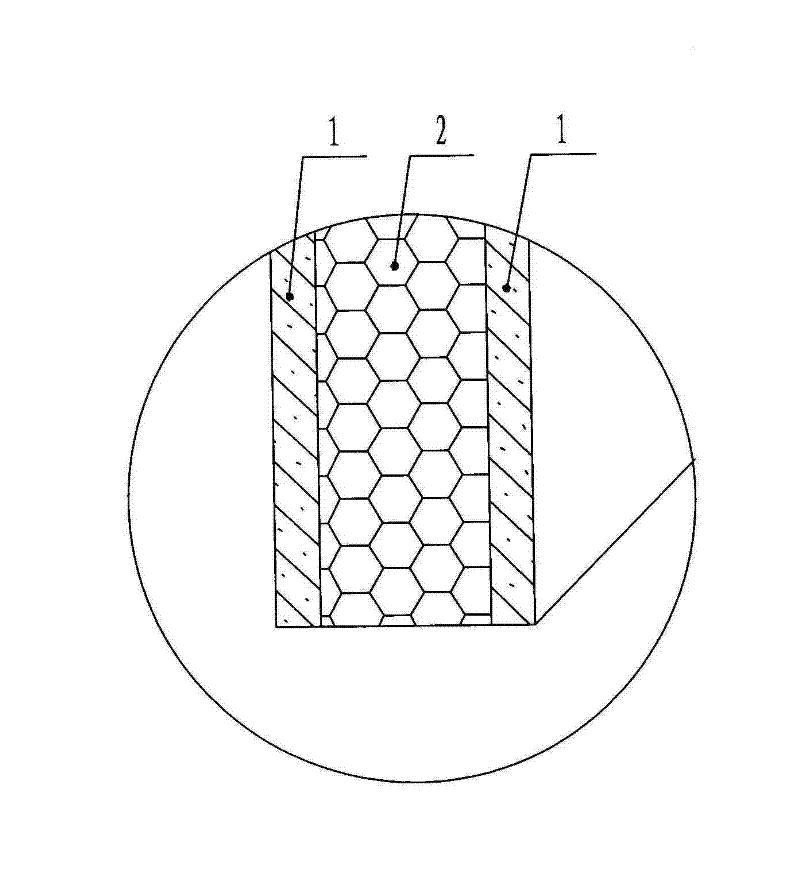

[0034] Such as Figure 3 ~ Figure 5 As shown, the panel implantation positioning device of the present invention includes a rigid body frame (3) of a frame structure welded by beams, longitudinal beams, and columns, a storage plate frame located in the frame and a group of vertical molds M arranged side by side. , a longitudinal inner slideway (10-1) and a longitudinal outer slideway (10) are arranged in a symmetrical parallel manner between the front and rear beams, near the left and right column sides, and each longitudinal inner slideway (10- 1) There are two vertical lift cylinders (14) in the chute of each longitudinal outer slideway respectively passed through the pulleys (11) in a suspended manner, and the pulleys are suspended in the chute of each longitudinal outer slideway (11) There are two o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com