Method for realizing accurate positioning of steel billet delivered into a heating furnace

A technology for precise positioning and heating of furnaces, applied to heat treatment furnaces, furnaces, furnace types, etc., can solve problems such as hidden dangers, uneven billets, and affecting the rhythm of steel loading, and achieve the effect of avoiding billet collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Technology of the present invention is:

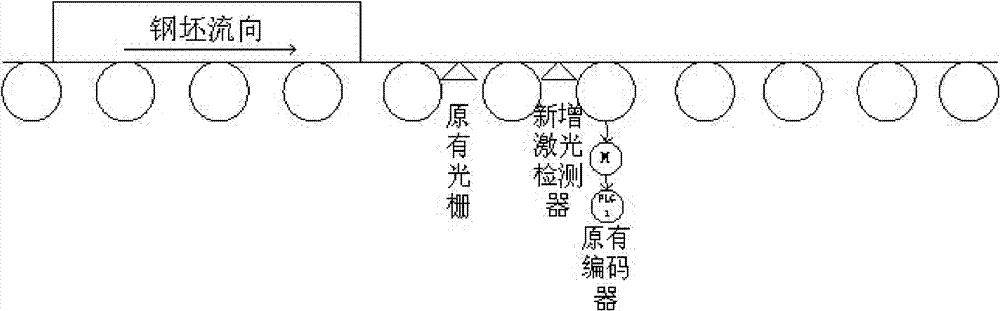

[0018] 1. Before the billet enters the heating furnace, add the laser detector at the entrance of the heating furnace and the position of the mounting bracket, so that the laser detector can be accurately irradiated on the center line of the roller table, and the angle is controlled between 30 degrees and 60 degrees. At the same time, reduce the gap at the opening end of the front end of the laser detector itself to (2mm-5mm), and turn the rotary button behind it clockwise to adjust the sensitivity indication value from 4 to 8.

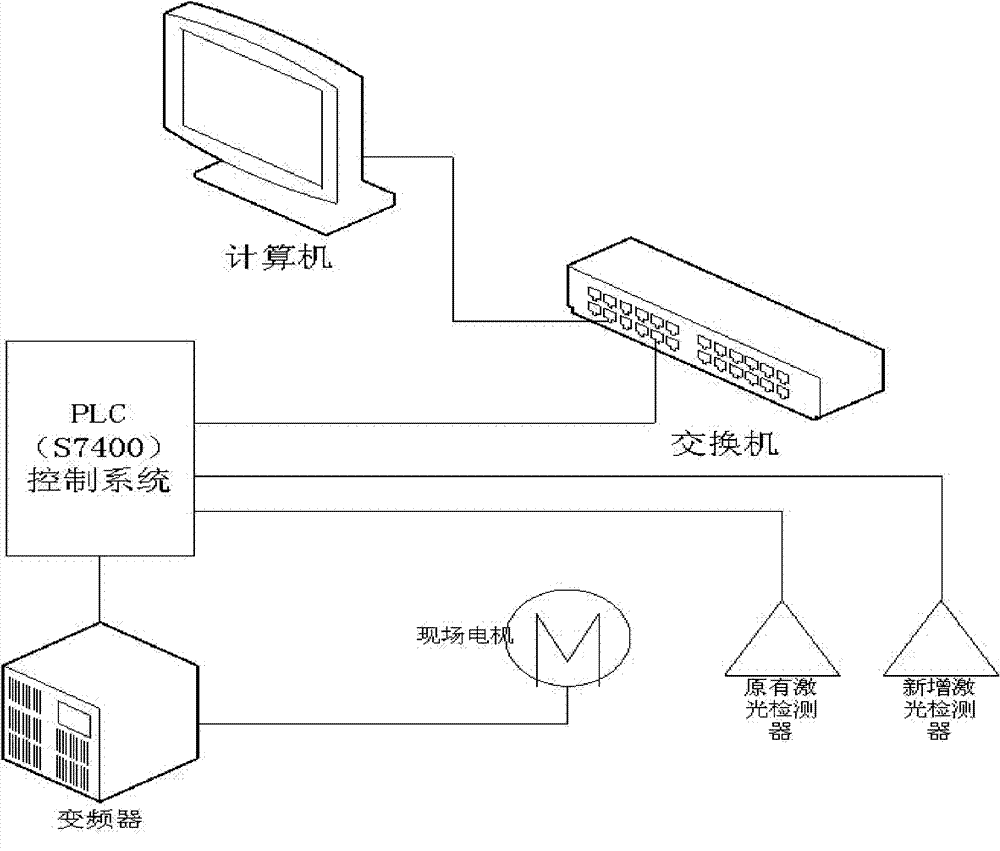

[0019] The conveyance of the steel billet into the furnace and the precise positioning of the billet on the furnace side are carried forward by the roller table, and pass through 3 automatic detection components during the transportation process (one of which is a newly added positioning laser detector, and one is an original tracking device). Grating, 1 photoelectric encoder for positioning), used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com