Connection structure for electromagnetic switch draw bar and shifting fork of starter

A technology of electromagnetic switch and connection structure, applied in the direction of contact drive mechanism, etc., can solve the problem of no idle travel of the pull rod, and achieve the effect of eliminating idle travel, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

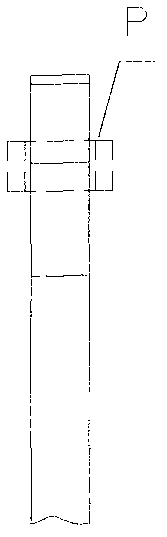

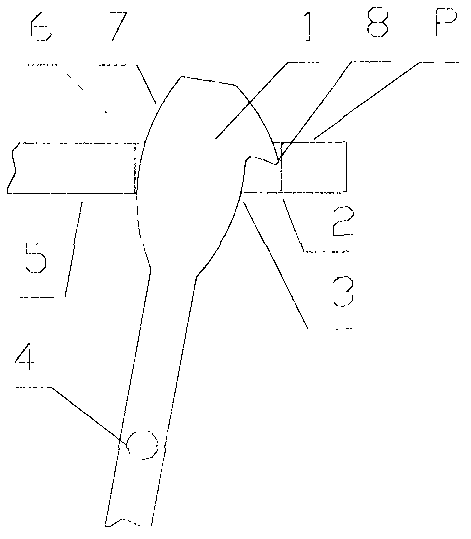

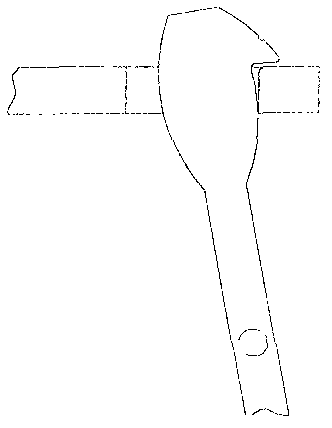

[0013] In the figure, 1. shift fork head, 2. pull rod out working surface, 3. shift fork head prior art pull out working surface, 4. shift fork pin, 5. pull rod, 6. pull rod push back list The working surface of the deflector, 7. Push back the working surface of the shift fork head, 8. The raised part of the shift fork head.

[0014] figure 1 , figure 2 In the first embodiment shown, the inside of the head of the pull rod (5) is a rectangular groove, the fork head (1) is sleeved in the rectangular groove, and the working surface of the raised portion (8) is the same as that of the prior art The working surfaces (3) are connected by a concave arc, and the concave arc does not contact the working surface (2) of the pull rod during the pulling process, and a plane P is above the working surface (2) of the pull rod. When the pull rod is in the initial position, there is no power-off gap between the working surface of the protruding part (8) of the shift fork head and the pull-out wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com