Organic light-emitting diode (OLED) display device, package structure and package method

A technology for display devices and packaging structures, which is applied in the manufacture of electric solid-state devices, semiconductor devices, and semiconductor/solid-state devices, etc., can solve problems such as affecting performance and damaging the organic light-emitting layer of OLED unit 6, and achieves enhanced packaging effect and good sealing performance. , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

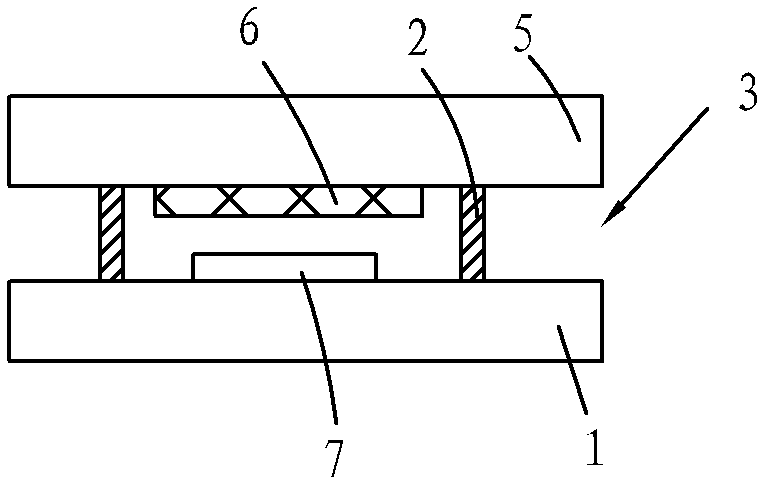

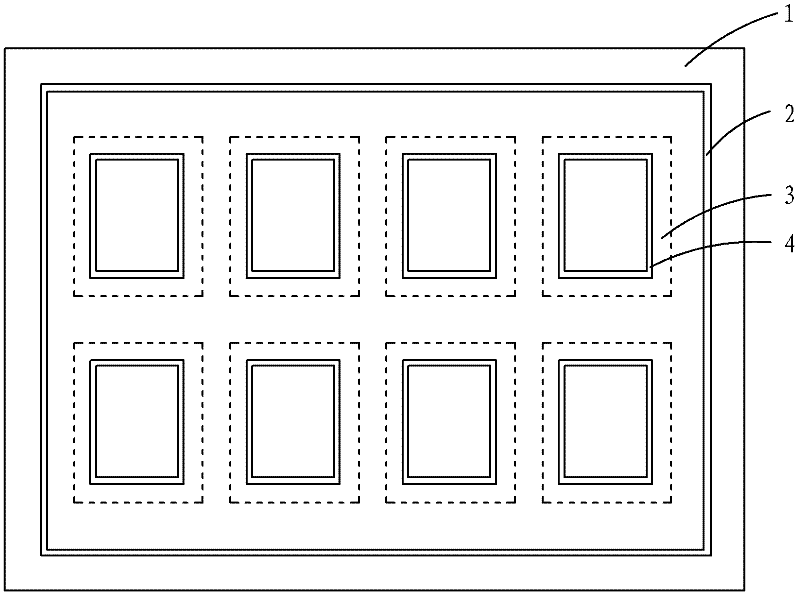

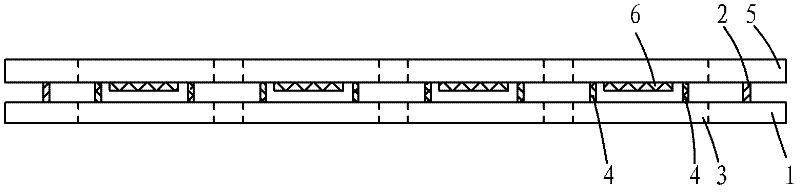

[0026] Such as figure 2 with image 3 As shown, a packaging structure of an OLED display device includes an uncut packaging glass cover plate 1 at the bottom and an uncut glass substrate 5 at the top, and a plurality of OLED units 6 are arranged in a matrix structure and attached to the glass substrate 5 In the lower part of the figure, the space range in the dotted box in the figure can be regarded as an OLED display device, and there is a circle of fritted glass 4 outside the periphery of each OLED unit 6, which is connected between the encapsulating glass cover plate 1 and the glass substrate 5 To seal each OLED unit 6 in the airtight space formed by the glass cover plate 1, the glass substrate 5 and the frit glass 4, the surrounding edges of the uncut packaging glass cover plate 1 and the uncut glass substrate 5 The UV resin 2 is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com