Fireproof bus duct

A technology of refractory busway and refractory layer, which is applied in the direction of open busbar installation, etc., and can solve the problems of poor fire resistance and loss of insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

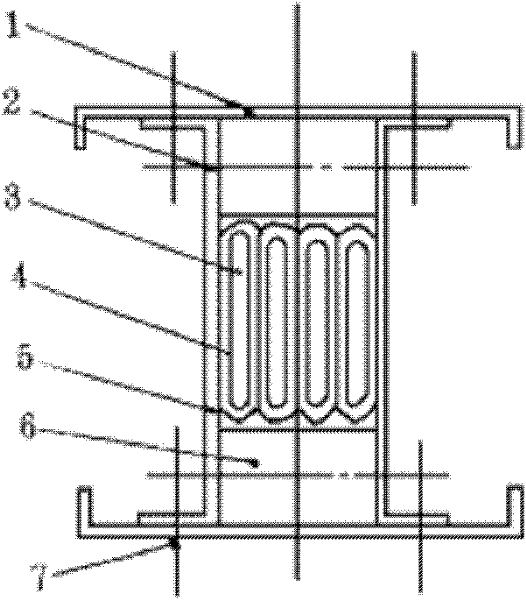

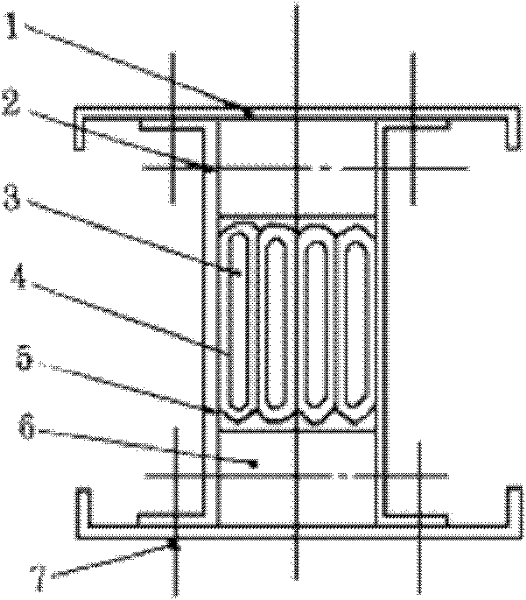

[0007] Such as figure 1 As shown, the present invention includes a shell cover plate 1, connecting bolts 2, conductive copper bars 3, a refractory layer 4, a shell side plate 5, an insulating spacer 6, and fastening bolts 7, wherein the refractory layer 4 is made of double or multiple layers. A layer structure is formed, and the refractory layer 4 of the double-layer structure includes inorganic materials and organic materials. The refractory layer 4 is designed as a multi-layer structure design. The selection of refractory layer 4 materials and the structure of the refractory layer are the key to the refractory busway. The present invention uses aluminum oxynitride as the main material for interlayer insulation, mainly because of its strong fire resistance, and in addition Avoid generation of harmful gases or halogens. At the same time, it has better plasticity than traditional ceramics. The refractory busway is burned at a high temperature of 980°C to 1040°C for 1.5h, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com