Heavy duty tire

A tire and tire crown technology is applied in the field of truck tires that improve the performance of stone inclusion. The effect of performance and tire regeneration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

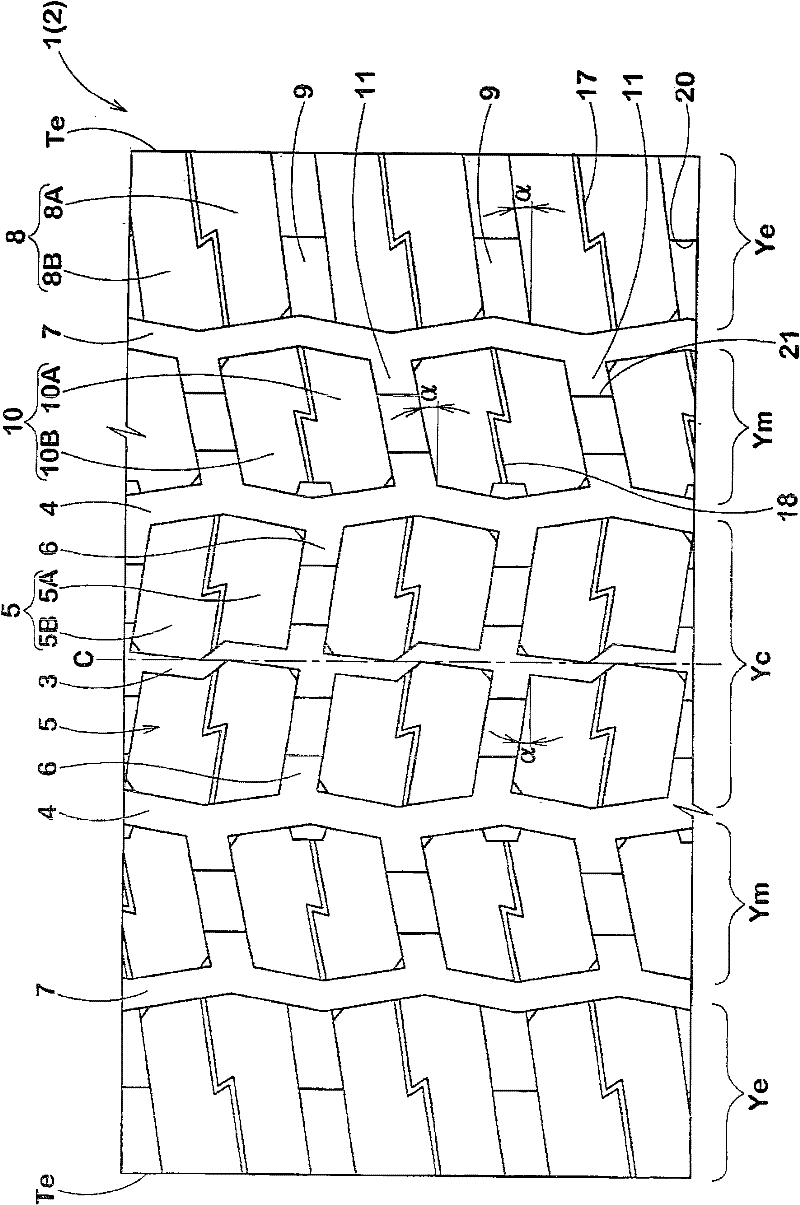

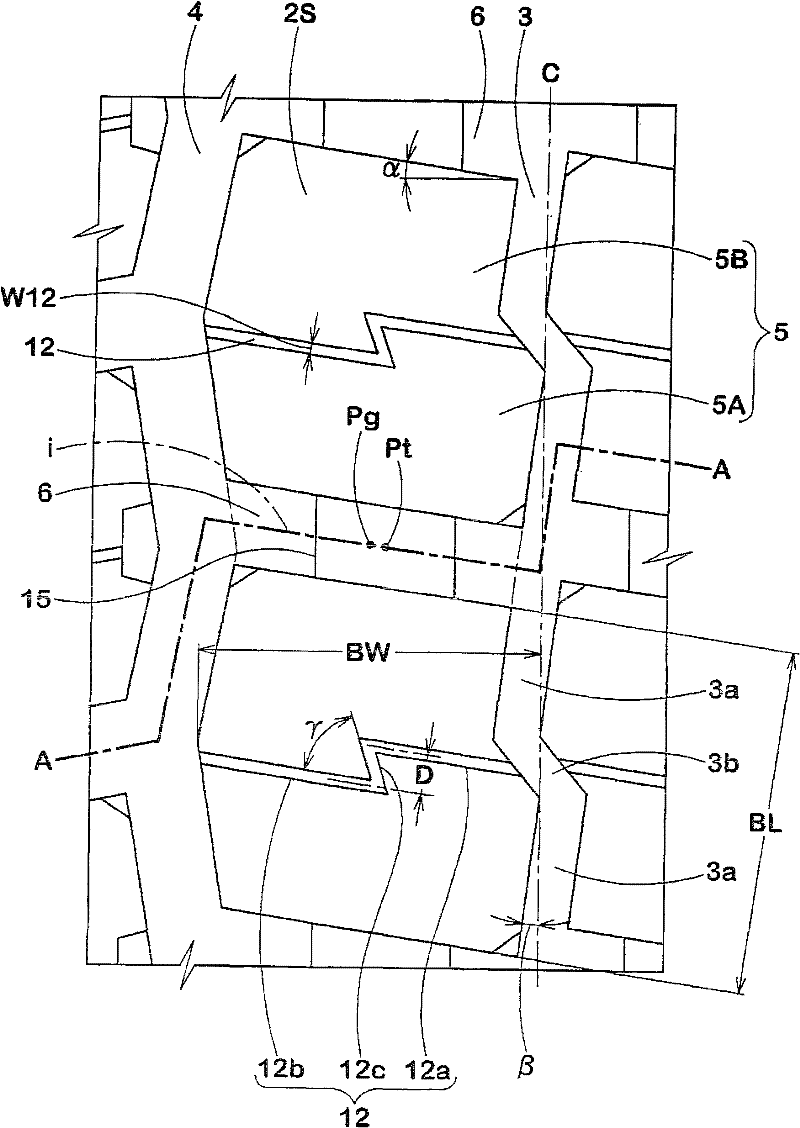

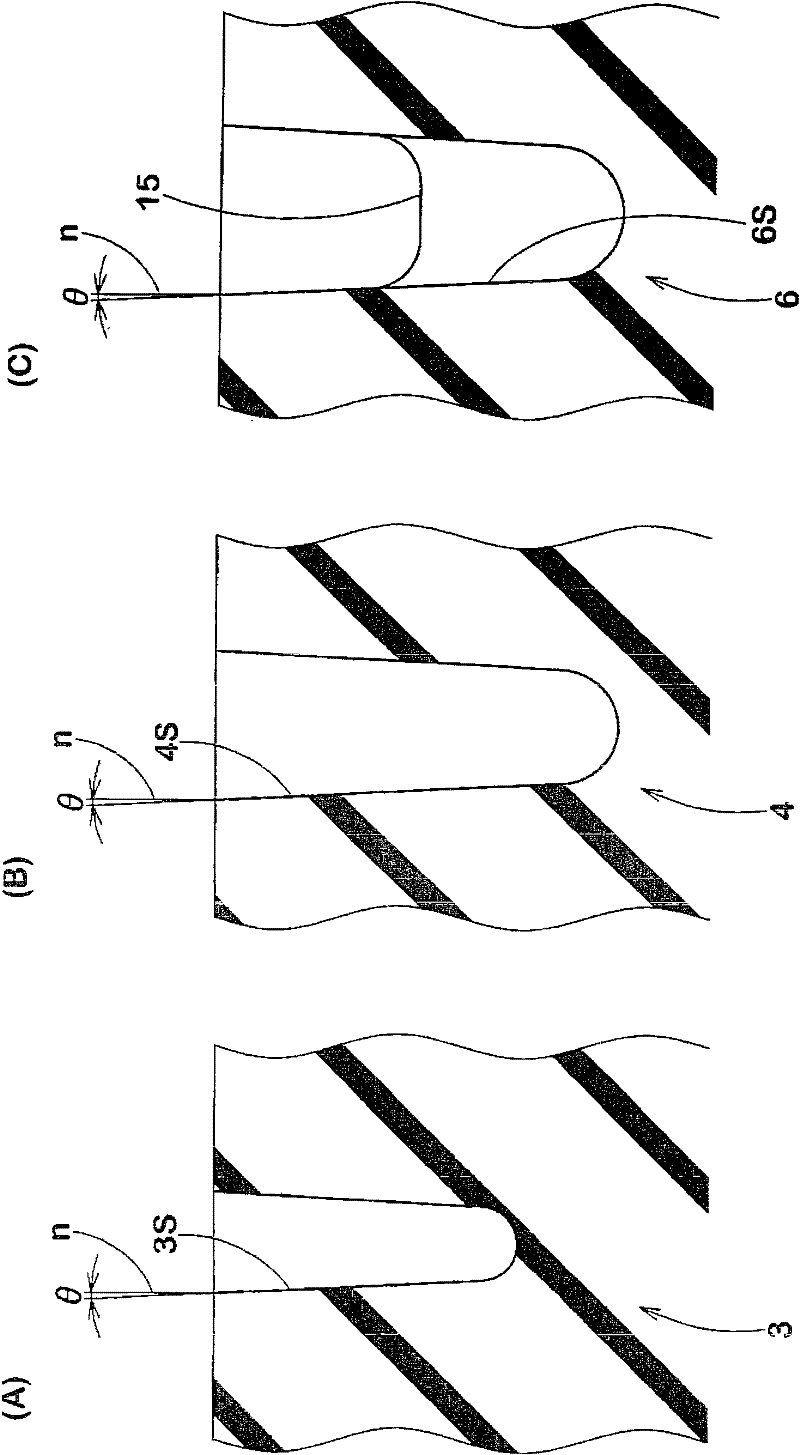

[0055] made a trial figure 1 The tread pattern shown is basic, and has the specifications shown in Table 1 (tire size 11.00 R20), and the stone inclusion performance, anti-uniform wear performance and drainage performance of each test tire were tested and compared with each other .

[0056] (1) Stone inclusion performance:

[0057] The test tire was mounted on a truck under the conditions of rim (7.50×20) and internal pressure (725kPa), and it was driven for 1500km on a road with gravel road as 2 / 3 and paved road as 1 / 3. , and confirmed the number of stone inclusions generated in the tread crown region after driving, and evaluated with the index of Comparative Example 1 being 100. The larger the value, the better the performance of stone inclusion.

[0058] (2) Partial wear resistance performance:

[0059] The heel and toe wear on the crown blocks of the tires after the rock inclusion performance test was visually inspected and evaluated with an index of 100 in Comparative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com