Rudderstock for ground transmission machine operated by rudderstock

A technology for ground conveying and rudder stock, applied in the direction of motor vehicles, transportation and packaging, lifting devices, etc., can solve the problems of undesired ergonomics, different operating characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

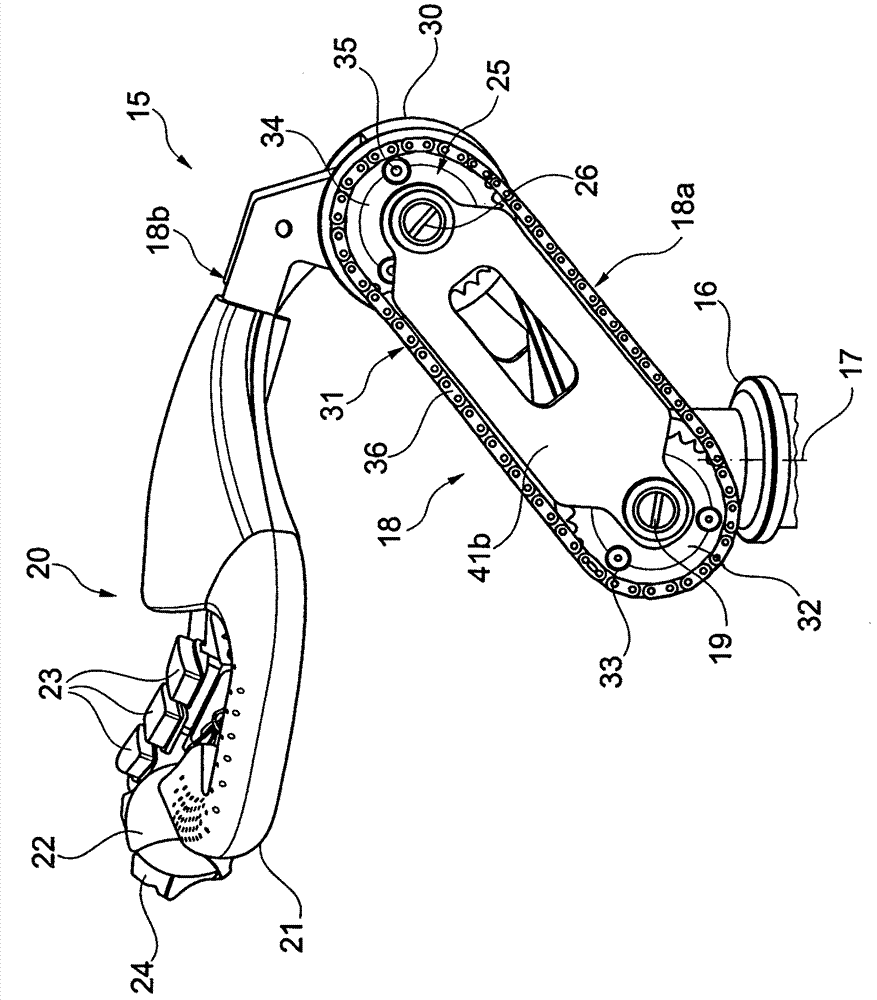

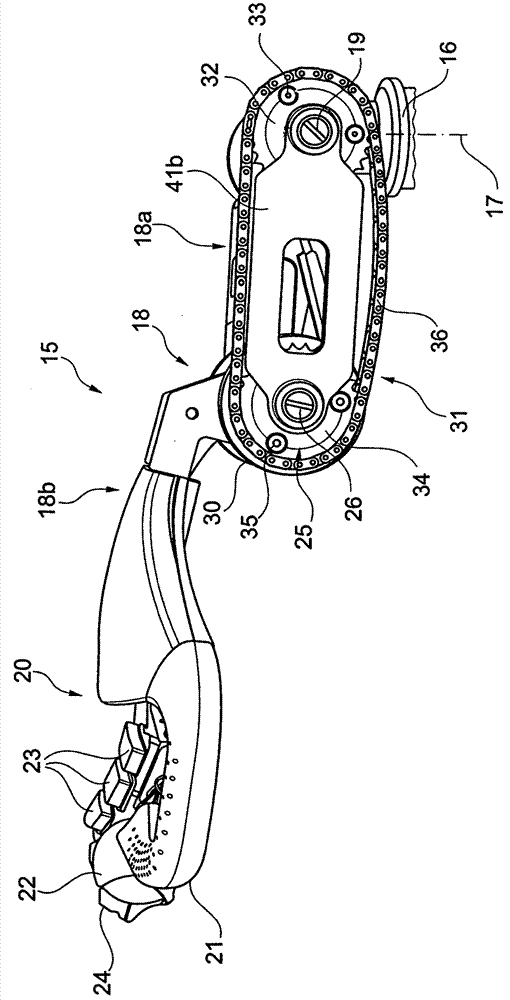

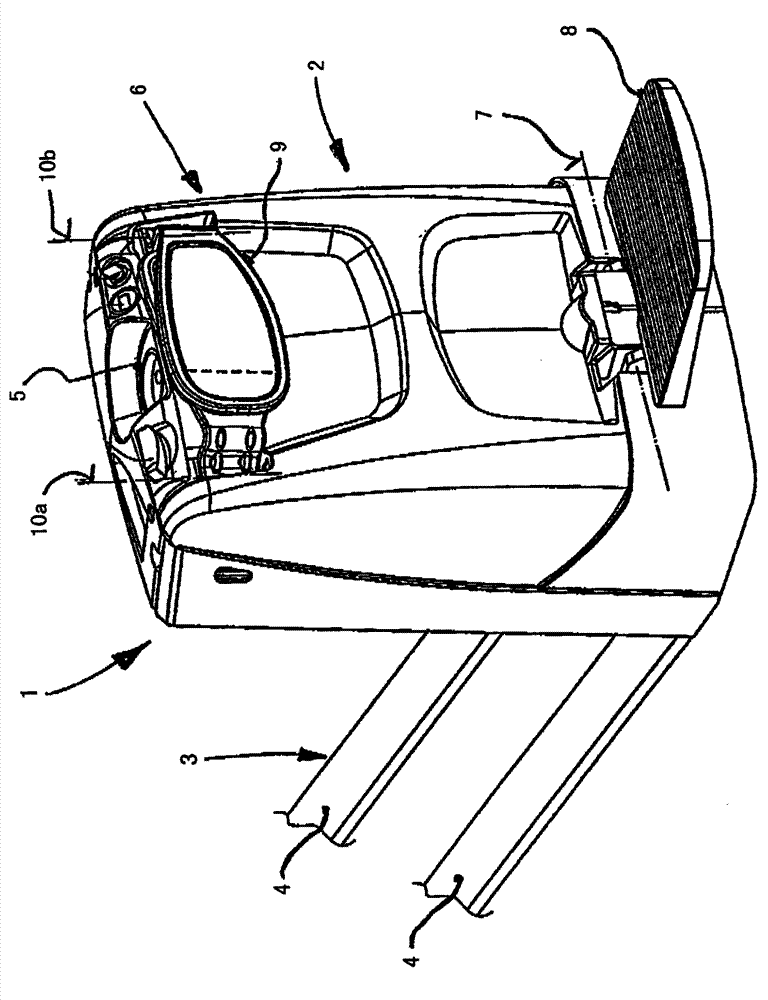

[0039] exist figure 1 10 shows a tiller-operated floor conveyor machine 1 according to the invention in the form of a storage technology palletizer, which is designed, for example, as a lift truck, in particular as a low-travel lift truck. The floor conveyor 1 has a drive part 2 and a load part 3 that can be raised or lowered relative to the drive part 2 . The drive part 2 comprises a load fork formed, for example, from two load arms 4 spaced apart laterally.

[0040] The load part 3 is supported on the track by means of load wheels which are arranged on the tips of the load arms 4 and are not shown in detail.

[0041] A traction drive unit (not shown in detail) is arranged in drive 2 pivotable about a vertical pivot axis, said traction drive unit comprising a drive wheel and a traction drive motor driving the drive wheel. The operator uses the figure 1 The floor conveyor 1 is actuated and steered by a tiller, not shown in detail, which is arranged on the upper side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com