Fluorescent material and white light emitting device

A technology for fluorescent materials and light-emitting devices, applied in the field of fluorescent materials, can solve the problems of easy thermal exhaustion of fluorescent powders and lack of high thermal stability, and achieve the effects of simple preparation process, high thermal stability, and high luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Referring to the chemical formula (Y 2.2 Ba 0.6 )Al 5 o 12 : Ce 0.2 Weigh Y proportionally 2 o 3 , CeO 2 、Al 2 o 3 with BaF 2 After the appropriate raw materials are uniformly mixed and ground in a mortar, the powder is placed in a reducing atmosphere at 1300-1500 ° C [N 2 / H 2 (5%)] sintered for 8-16 hours to make its luminescent center Ce 4+ Revert to Ce 3+ , the yellow product can be obtained.

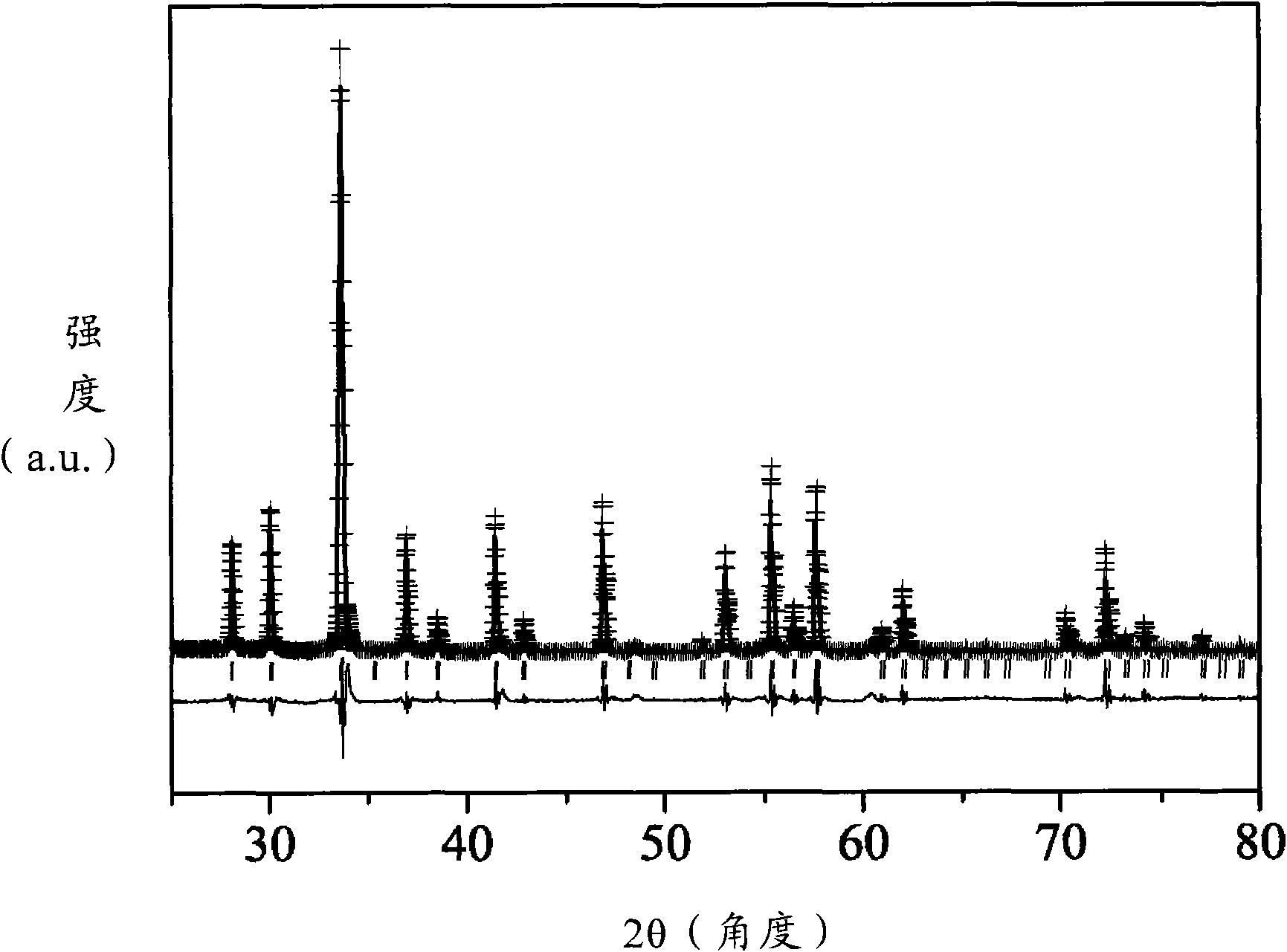

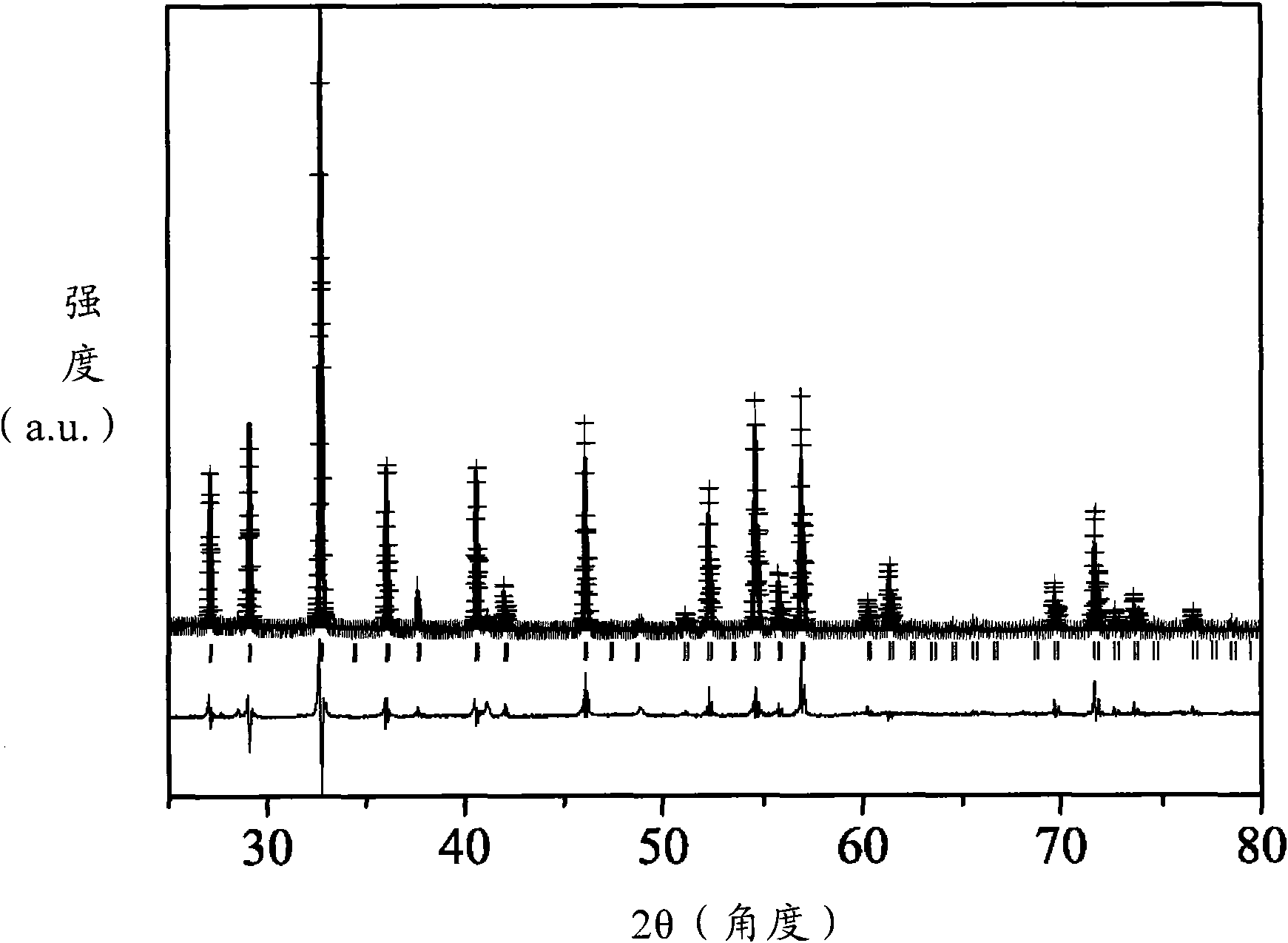

[0029] Y prepared by solid-state synthesis method according to the embodiments of the present invention 2.8 al 5 o 12 : Ce 0.2 product and (Y 2.2 Ba 0.6 )Al 5 o 12 : Ce 0.2 The X-ray powder diffraction pattern of product identifies its crystalline phase purity, respectively as Figure 2a and Figure 2b shown. According to the actuarial calculation of the structure, Table 1 shows the lattice parameters and reliability index of Comparative Example 1, where χ 2 =3.41,R wp = 8.83% with R p =5.68%, the lattice parameter is a=b=c=12.0225(1) The lattice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com