Method for directionally drilling inclined hole in steeply-inclined stratum

A technology of steep inclination and formation, applied in the directions of directional drilling, drilling equipment and methods, drilling equipment, etc., can solve the problems of difficulty in drilling up and down, small annulus clearance between drilling tools and well wall, difficult bending of drilling tools, etc. The effect of shortening the construction period, improving the quality of geological exploration and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

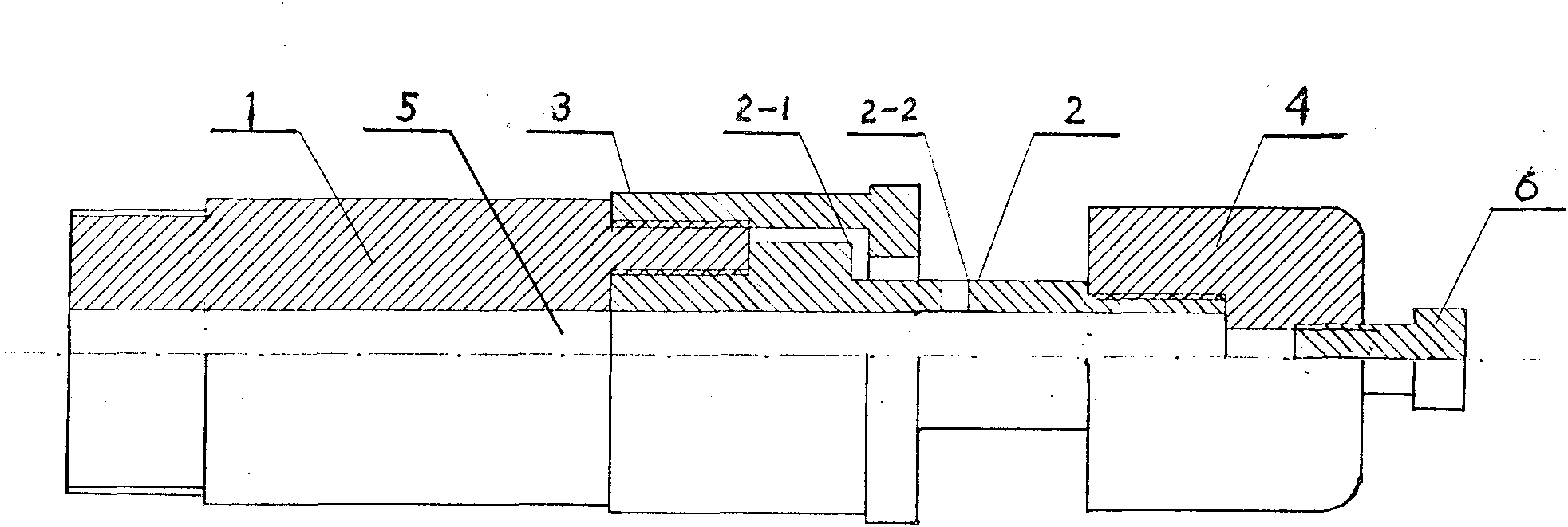

[0020] The method for carrying out directional inclined hole drilling in steeply inclined formations of the present invention comprises the construction of straight hole section, the construction of deflecting section and the construction of slightly increasing hole inclined section, and its steps are as follows:

[0021] 1. Construction of straight hole section

[0022] use The 130mm alloy drill bit drills the hole to the bedrock and goes into the 127mm orifice pipe and cemented. The specific process is as follows:

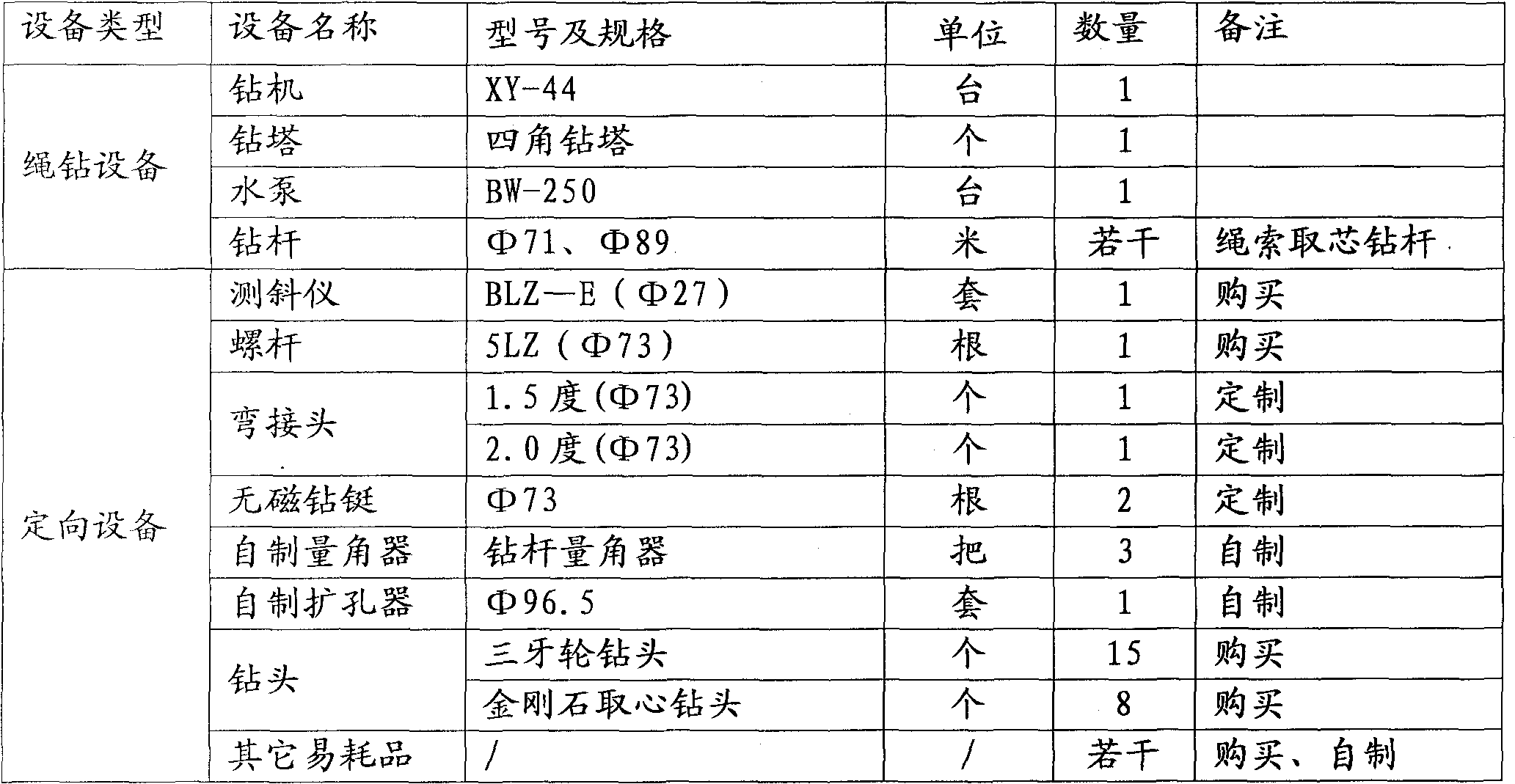

[0023] (1) Install drilling rigs, drilling towers, water pumps, generator sets and other equipment and facilities according to the specifications;

[0024] (2) Prepare drill bits, drill pipes, casings, special joints, special tools and other equipment required for this construction;

[0025] (3) Prepare drilling tools according to the drilling tool combination and requirements required for drilling, and wait for acceptance of the drilling;

[0026] (4) Ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com