Method for cold starting a steam turbine

A steam turbine and cold start technology, applied to engine functions, steam engine devices, engine components, etc., to achieve the effects of improving personnel safety, simplifying equipment, and shortening warm-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Exemplary embodiments of the present disclosure will now be described with reference to the drawings, in which like reference numerals are used to refer to like elements. In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of the present disclosure. However, the present disclosure may be practiced without these specific details and is not limited to the exemplary embodiments disclosed herein.

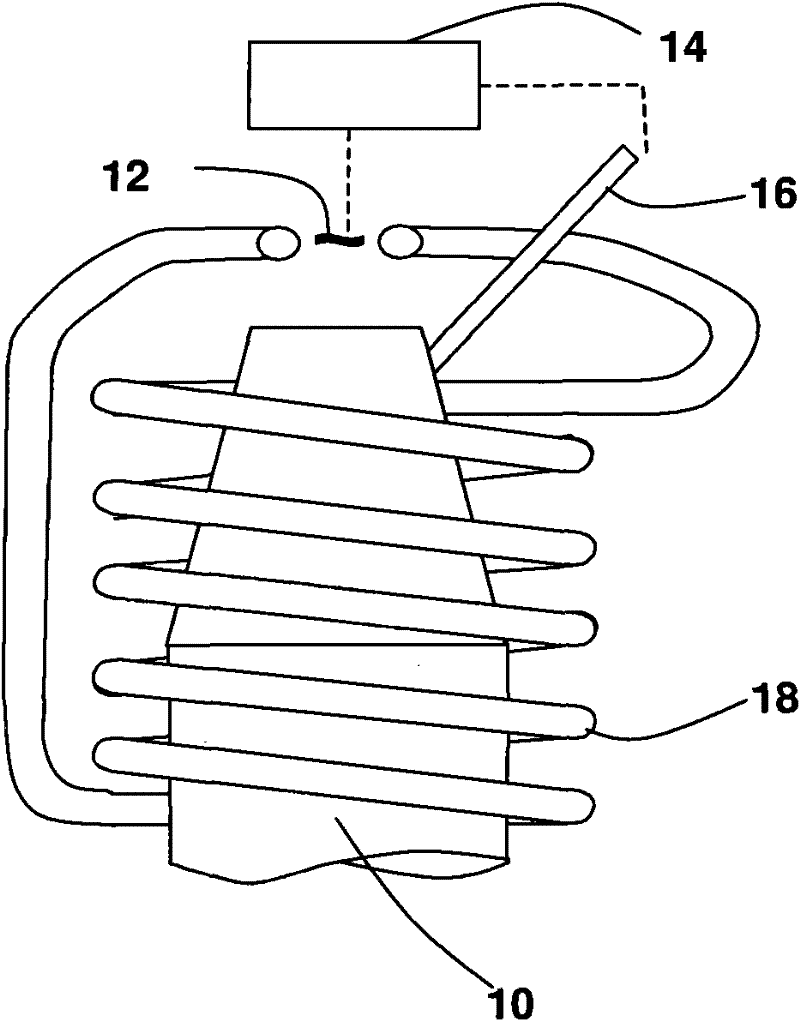

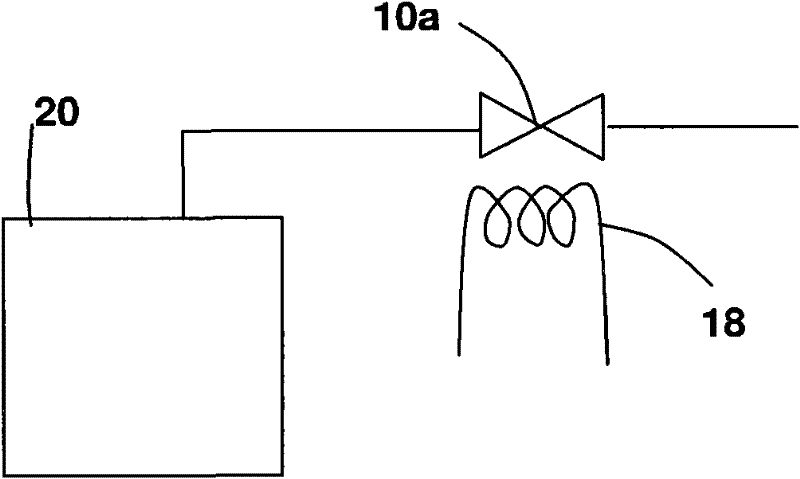

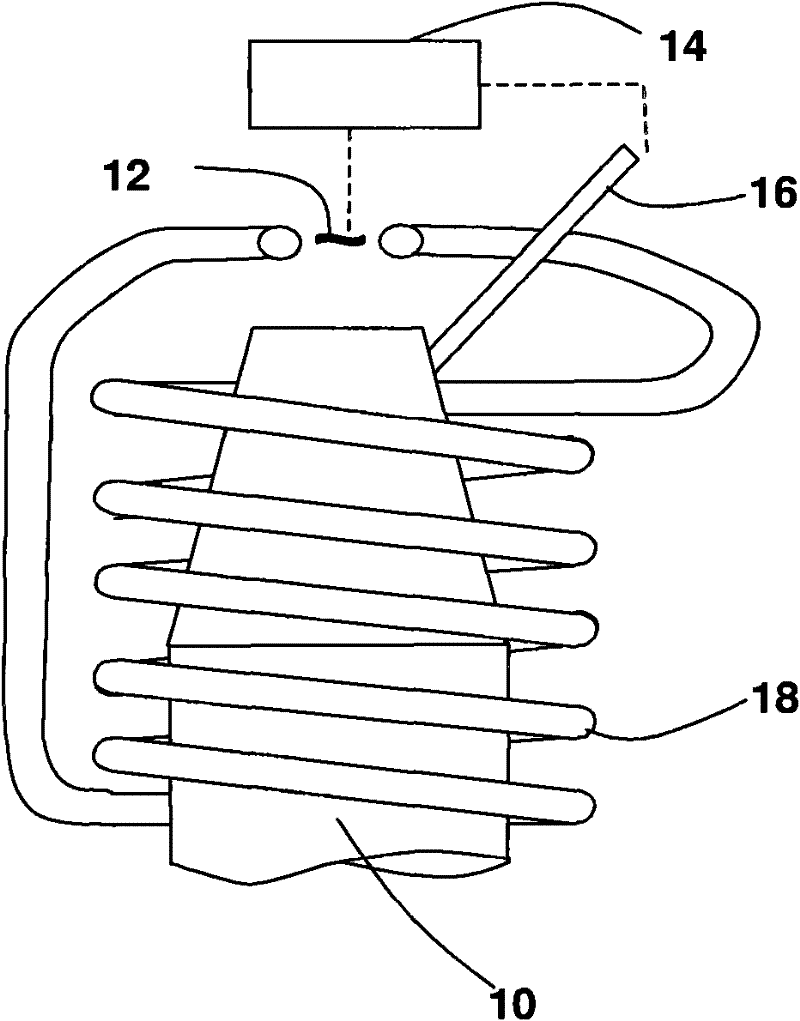

[0015] figure 1 An exemplary embodiment of a steam turbine component 10 with a heating system is shown. The purpose of the heating system is to preheat the component 10 to a desired temperature, for example to start or restart the steam turbine 20, while limiting thermal stress within the component 10 to an acceptable level.

[0016] In the exemplary embodiment, steam turbine component 10 is made of an electrically conductive material. This allows the component 10 to facilitate eddy cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com