Electrical machine and a method for assembling it

A machine, electric technology used in the field of assembling electric machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

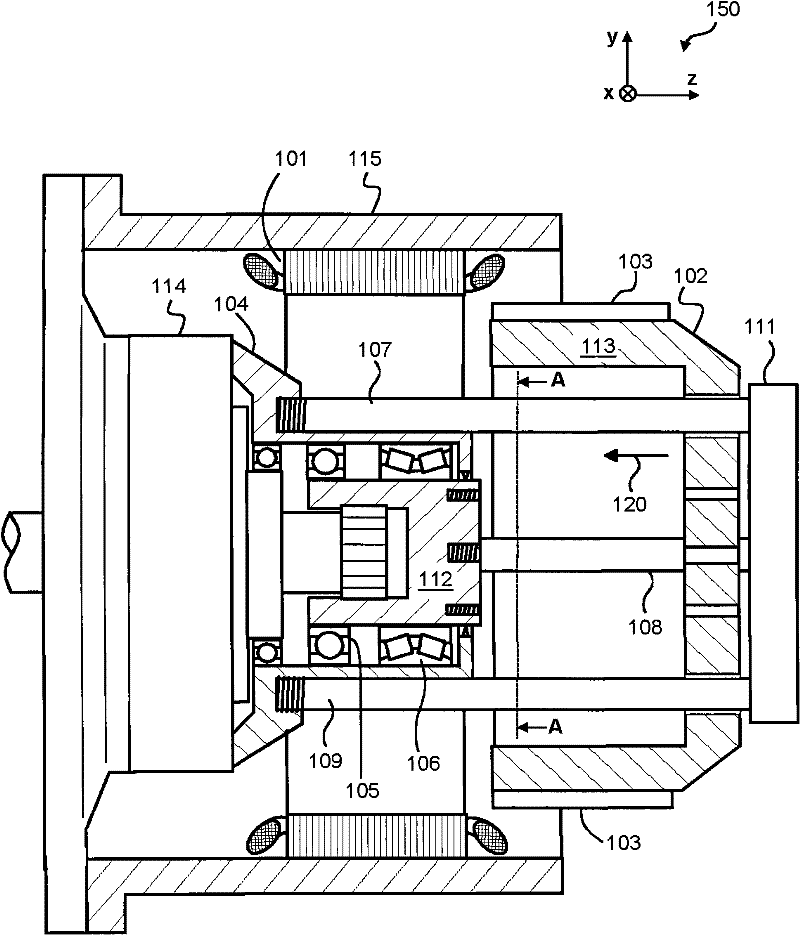

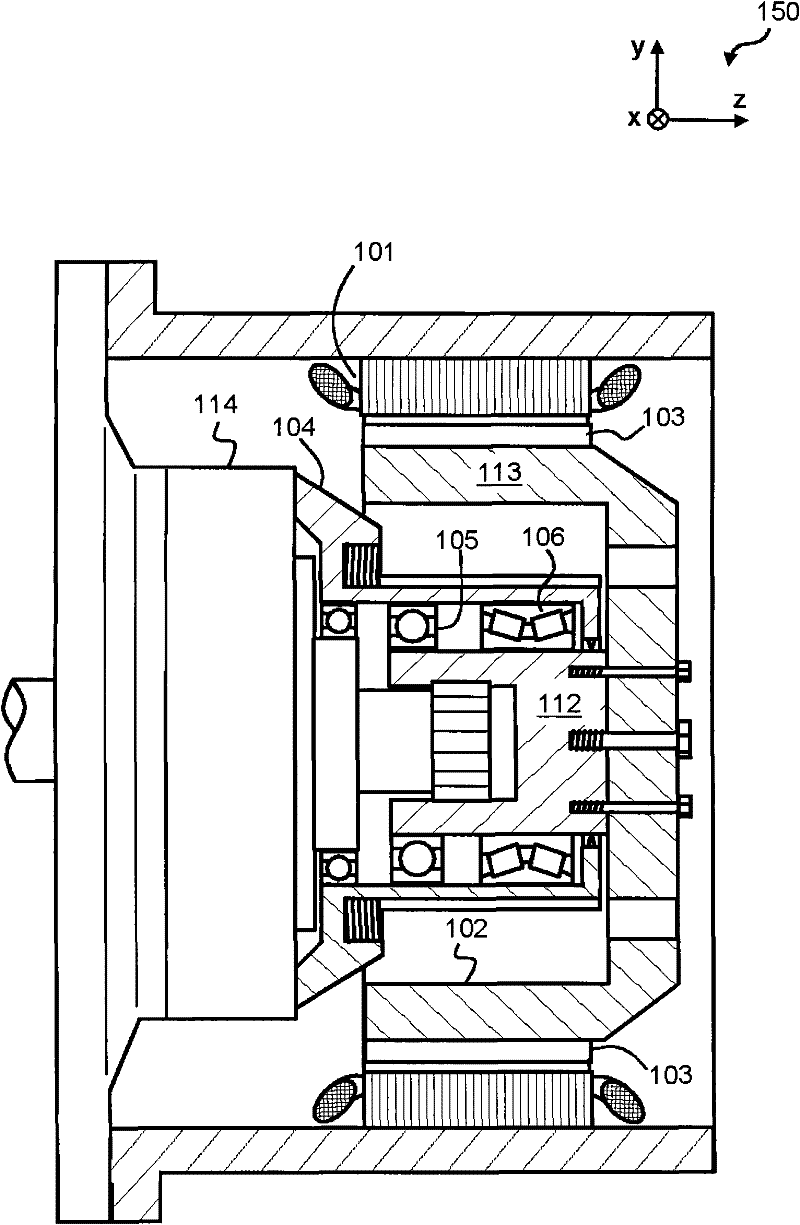

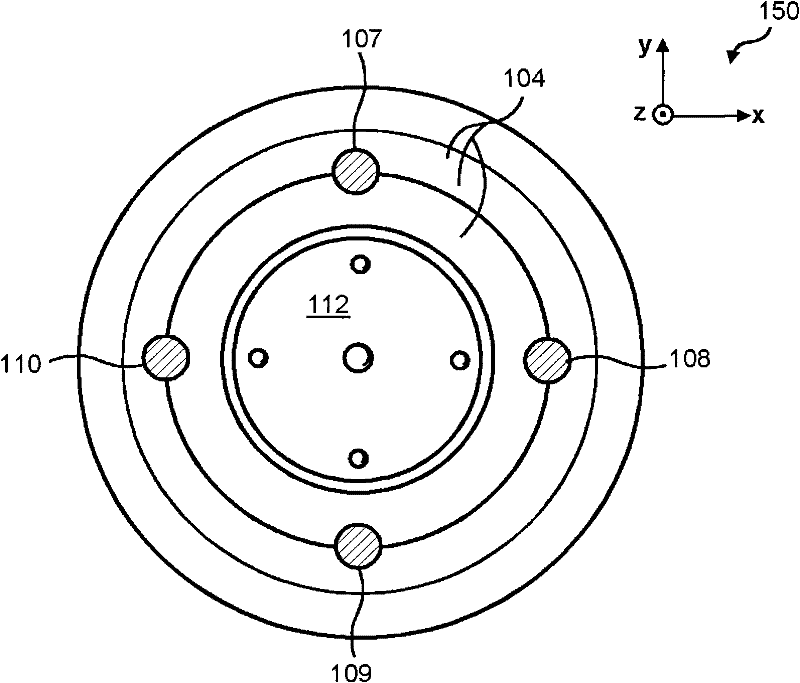

[0030] Figure 1a shows a schematic cross-sectional view of an electric machine according to an embodiment of the invention in a condition in which the rotor is being installed, and Figure 1b A schematic cross-sectional view of the electric machine is shown in a condition where the rotor is in its final position. Figure 1c showing along Figure 1a A view of a section taken along the line A-A shown. exist Figure 1a-1c In , the axial direction is the direction of the z-axis of the coordinate system 150 . The electric machine comprises a stator 101 comprising a laminated stator core and stator windings. The rotor 102 of the electric machine comprises a frame 113 and permanent magnets 103 attached to the frame 113 . The electric machine comprises a mechanical support structure 104 comprising bearings 105 and 106 arranged as in Figure 1b Support the rotor relative to the stator when the rotor is shown in its usual position. exist Figure 1a-1c In the exemplary configurati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com