Method for operating a retarder

An operation method and technology of reducer, applied in the direction of brake, brake type, hydraulic brake, etc., can solve problems such as complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

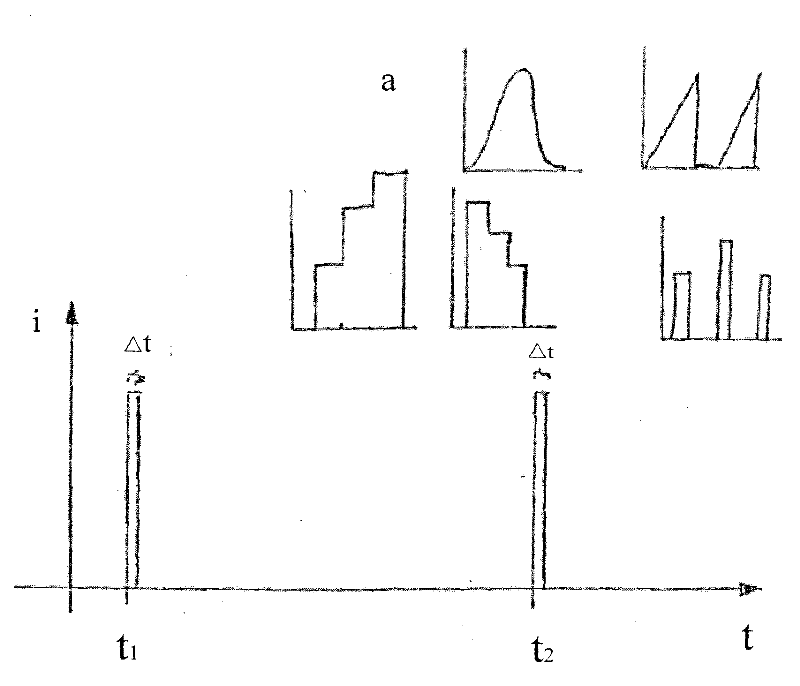

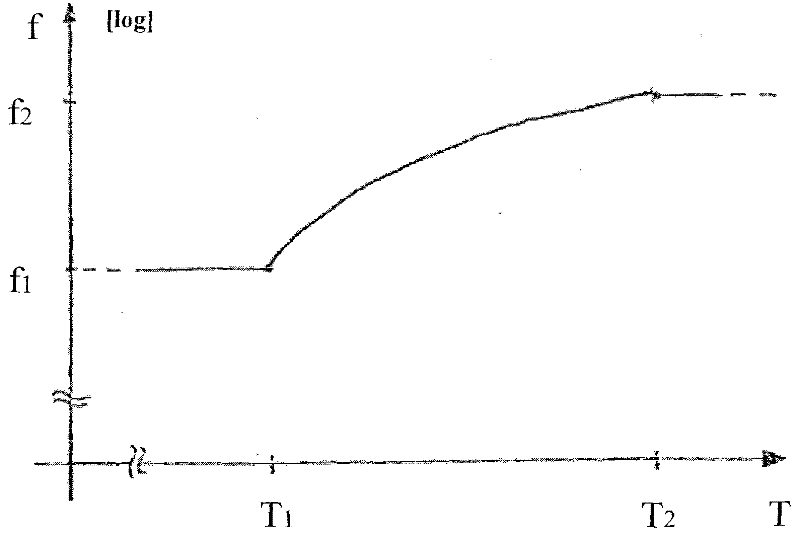

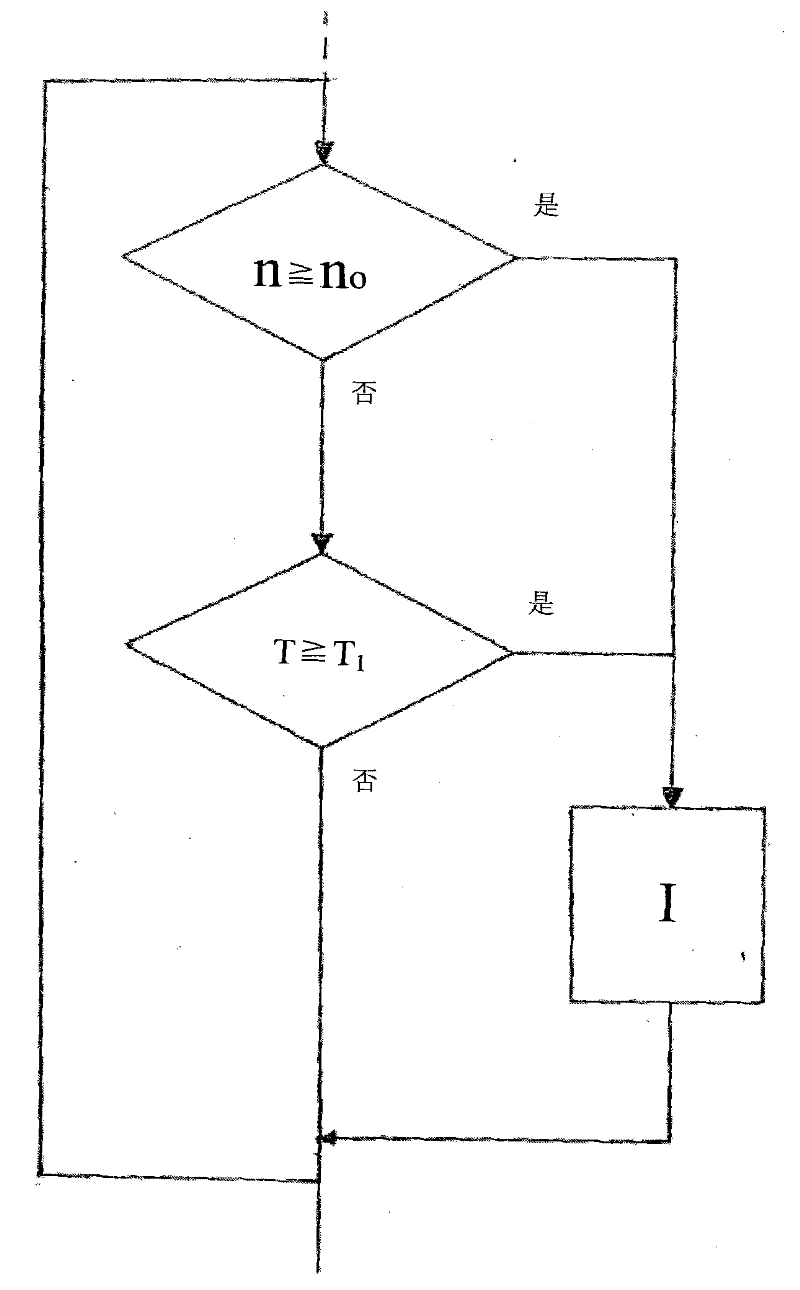

[0026] The speed reducer installed in the vehicle power transmission system is common and typical for professionals in the field of speed reducer technology as a wear-free braking device, so the specific content of the operating method designed by the present invention will not be discussed. describe. Fundamentally, the various structures of hydrodynamic reducers are applicable to the use of the reducer operation method, regardless of whether they use oil, water and / or water mixture as the working medium.

[0027] The manner in which the retarder is filled with working medium for the braking operation is not or only a secondary effect of the invention. Fundamentally, it is conceivable and common to fill the working chamber of the reducer with suitable arrangements, such as solenoid valves, working medium in the corresponding reservoir, which has a higher pressure than the working chamber. As long as the valve is opened, the working medium will flow into the working chamber of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com