Preparation method of flaky processed cheese and prepared flaky processed cheese

A technology for processed cheese and flakes, applied in cheese substitutes, dairy products, applications, etc., can solve problems such as excessive temperature or long time melting degree, etc., achieve good taste and taste, simple production process, The effect of state stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

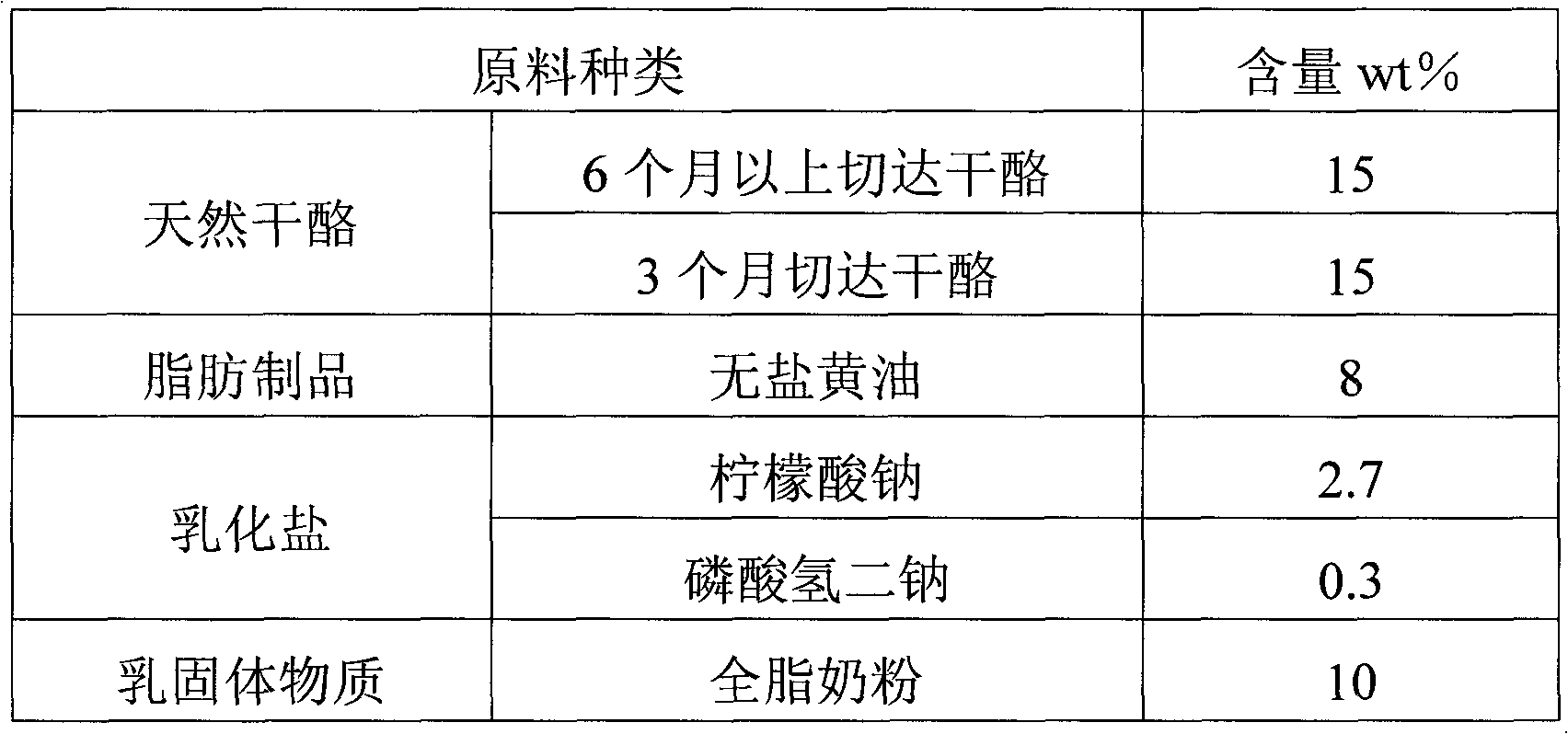

[0034] Raw material formula:

[0035]

[0036]

[0037] Preparation:

[0038] ① Cut the natural cheese and fat products into pieces according to the ratio of raw materials in the above table, then add the rest of the raw materials, shear and mix, heat up to 70°C for initial melting, and stir for 5 minutes to obtain the mixture;

[0039] ②Sterilization: The mixture is sterilized by ultra-high temperature instantaneously, and the temperature is raised to 135°C and kept for 9s;

[0040] ③ Stirring and emulsification: at a temperature of 90°C, the stirring speed is 800rpm, stirring for 2min;

[0041] ④Rapid cooling: use the flowing water immersion cooling method, the cooling time is 30min, the central temperature is below 28℃, and the product is ready to be formed.

[0042] After testing, the product index is 56.9% of moisture; 18.0% of fat; 12.5% of protein; the percentages are the mass percentages of each component in the total amount of the flaky processed cheese.

Embodiment 2

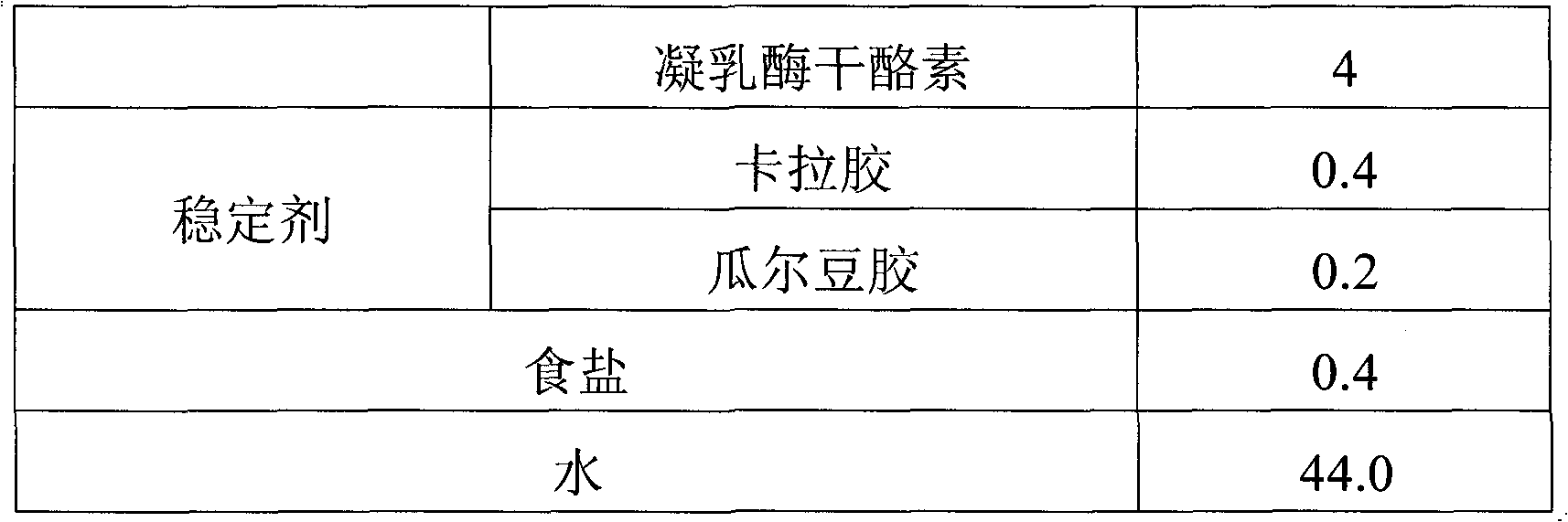

[0044] Raw material formula:

[0045]

[0046]

[0047] Preparation:

[0048] ① Cut the natural cheese and fat products into pieces according to the raw material ratio in the above table, then add the rest of the raw materials, shear and mix, heat up to 80°C for initial melting, and stir for 5 minutes to obtain the mixture;

[0049] ②Sterilization: Pasteurize the mixture, raise the temperature to 85°C, and keep it for 5 minutes;

[0050] ③ Stirring and emulsification: Stir for 6 minutes at a temperature of 85°C and a stirring speed of 500 rpm;

[0051] ④Rapid cooling: Cooling in a cooling tunnel, the cooling time is 30 minutes, and the central temperature is below 30°C, and the product is ready to be formed.

[0052] After testing, the product index is 47.6% of water; 32.0% of fat; 14.0% of protein; the percentage is the mass percentage of each component in the total amount of flaky processed cheese.

Embodiment 3

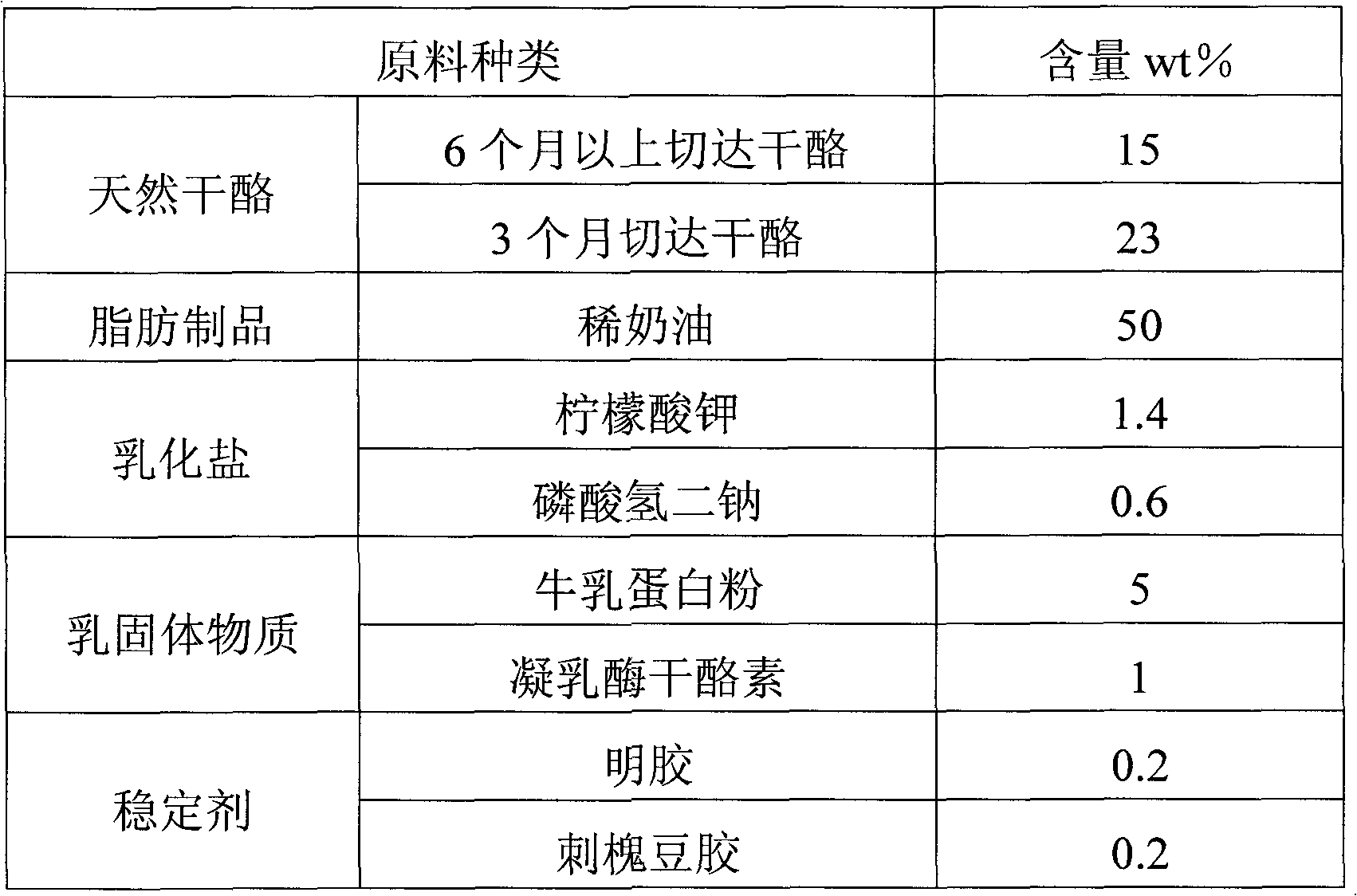

[0054] Raw material formula:

[0055]

[0056] Preparation:

[0057] ① Cut the natural cheese and fat products into pieces according to the ratio of raw materials in the above table, then add the rest of the raw materials, shear and mix, heat up to 70°C for initial melting, and stir for 5 minutes to obtain the mixture;

[0058] ②Sterilization: Ultra-high temperature instantaneous sterilization, heating up to 140°C and keeping for 2s;

[0059] ③ Stirring and emulsification: at a temperature of 80°C, the stirring speed is 800rpm, stirring for 10min;

[0060] ④Rapid cooling: Cooling by immersion in flowing water, the cooling time is 20 minutes, the central temperature is below 25°C, and the product is ready to be formed.

[0061] After testing, the product index is 56.7% of moisture; 21.9% of fat; 10.0% of protein; the percentages are the mass percentages of each component in the total amount of the flaky processed cheese.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com