hammer mill

A hammer mill and hammer technology, applied in grain processing and other directions, can solve the problems of low output of the mill, troubled by the improvement of mill technology, poor uniformity, etc. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

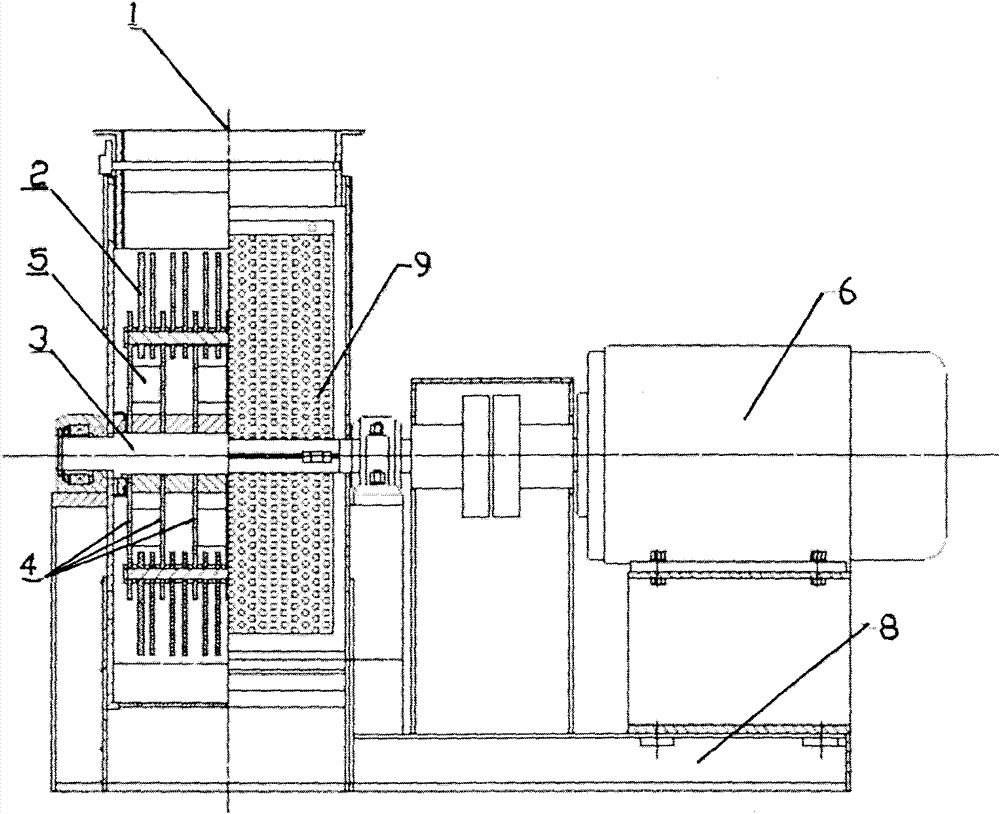

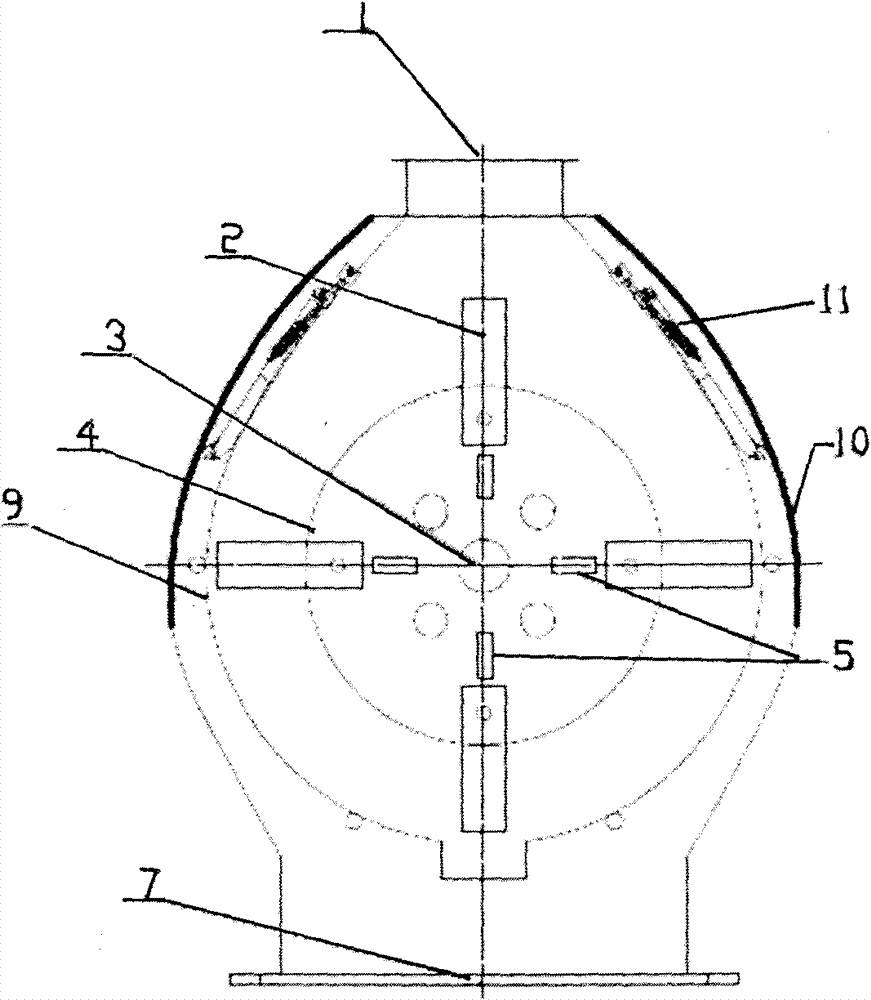

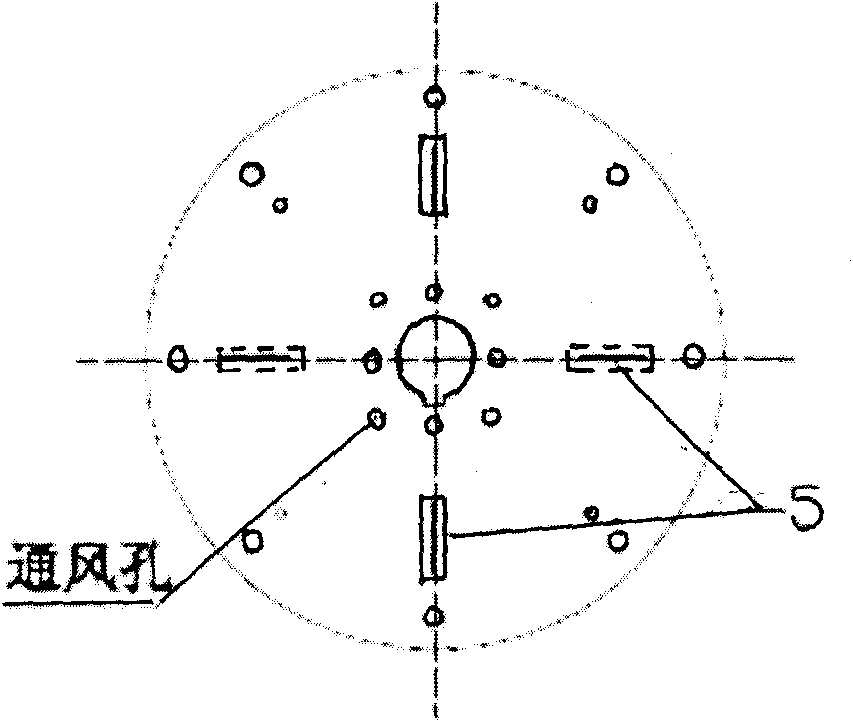

[0016] Example 1: figure 1 , figure 2 , a horizontal pulverizer, pulverizer inlet (1), hammer (2), rotor (3), turntable (4) mounted on the rotor, wind blades (5), motor (6), pulverizer Machine discharge port (7), machine body (8), sieve sheet (9), door (10), press screen frame (11) etc. are composed. its rotor image 3 , the fan blades are installed between the turntables, and 2 fan blades are installed between each 2 turntables. The direction of the two fan blades is 180 degrees, on the same line passing through the center of the circle, and the distance from the center of the circle is equal. The distance between adjacent turntables The fan blades are staggered at 90 degrees, so that not only vertical wind pulsation but also horizontal wind movement can be formed on the inner surface of the screen, which destroys the uniform centrifugal force inside the screen and the negative pressure outside the screen, and makes the qualified materials more efficient. It is easy to si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com