Discrete floating type support method of large thin plate workpiece

A support method and floating technology, applied in workpiece clamping devices, metal processing machinery parts, supports, etc., can solve problems such as deformation of sheet metal, deformation of large thin plate workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

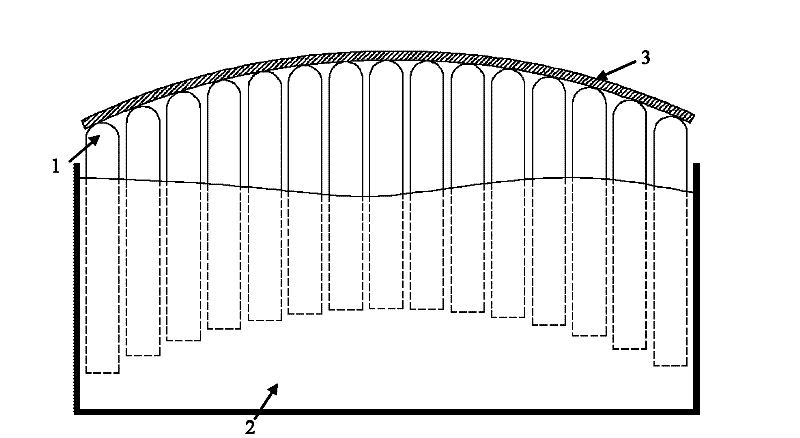

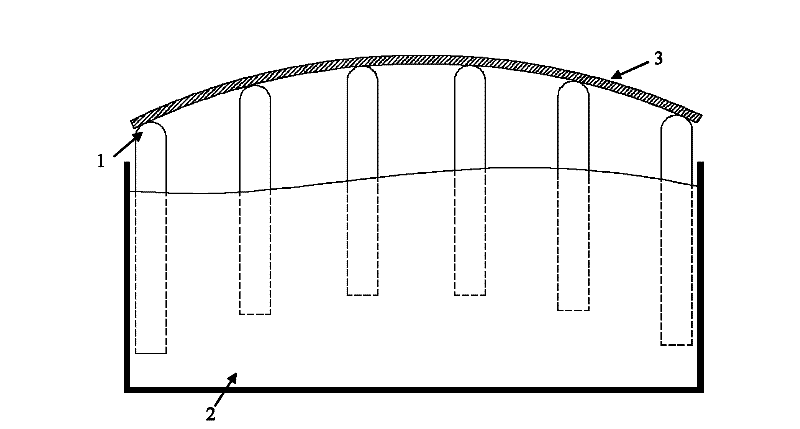

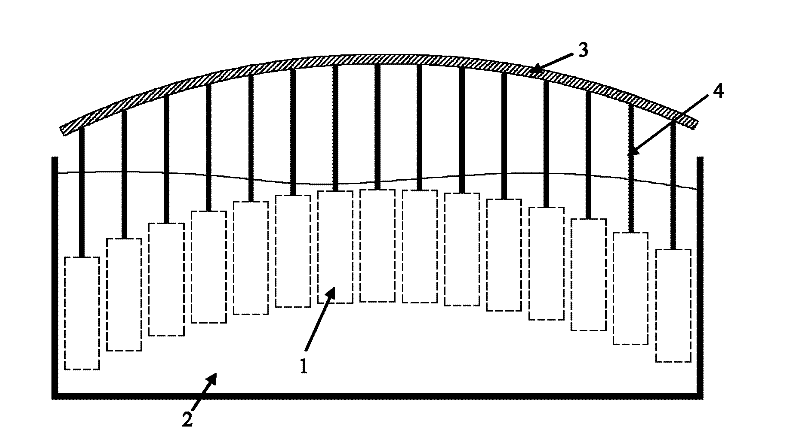

[0016] figure 1 is a schematic diagram of a densely arranged discrete floating support method, in which many floating units 1 are densely arranged in a liquid 2; figure 2 It is a schematic diagram of a discrete floating support method arranged at large intervals. In this method, several floating units 1 are put into the liquid 2 at relatively large intervals. The discrete floating support method of dense arrangement or large interval arrangement changes the buoyancy value of each floating unit 1 through the depth of each floating unit 1 in the liquid 2, so as to realize the discrete floating support method of large size or high precision large thin plate workpiece 3 support. When a part of the floating unit 1 is above the liquid surface, the buoyancy value increases with the increase of the displac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com