Primary explosive automatic depiler

An automatic disc splitting machine and detonator technology, applied in explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of low production efficiency, large safety hazards, and high labor intensity, so as to reduce labor intensity, use safety, and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

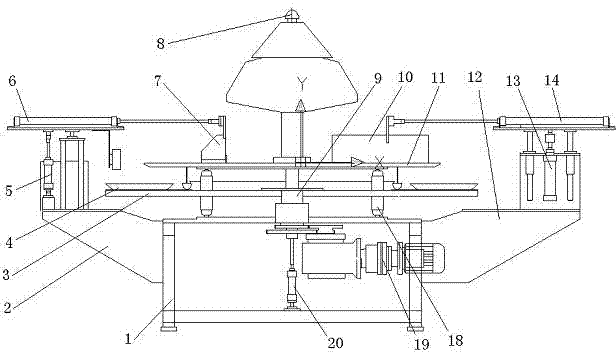

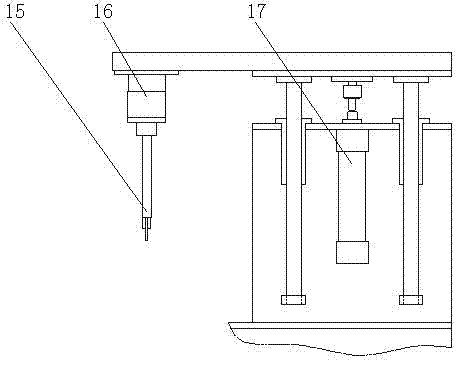

[0018] The detailed content and specific implementations of the present invention will be further described below in conjunction with the drawings.

[0019] See figure 1 , The initiating charge automatic disc sorting machine of the present invention includes a turntable device, a charge stacking device, a charge splitting device, a rake leveling device and a charge turning device. The turntable device includes a drying disc turntable 3, a drying disc 4, a main shaft 9, and a connecting device. The medicine turntable 11, the auxiliary roller 18 and the spindle motor 19 are connected to the spindle 9 and supported on the base 1 through the auxiliary roller 18; the spindle 9 is connected to the spindle motor 19 and is driven to rotate by the spindle motor 19; The dry plate 4 is arranged on the circumference of the drying plate turntable 3, the drying plate turntable 3 is connected to the main shaft 9, and the main shaft motor 19 is simultaneously driven to rotate in steps;

[0020] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com