Bulk feeder

A feeder and bulk material technology, applied in the direction of conveyor objects, electrical components, transportation and packaging, etc., can solve problems such as low efficiency and difficulty in utilizing the capacity of the loader

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the present invention will be described below, and the terms "identical" and "identical" used in the description include tolerances in dimensions, and do not mean complete coincidence or complete identity. Also, in the following description, the figure 2 The left, right, front and depth of (A) and other pictures (except figure 1 (A)~ figure 1 The corresponding directions of (C)) are called front, back, left and right, respectively.

[0052] Parts to be supplied by bulk material feeders

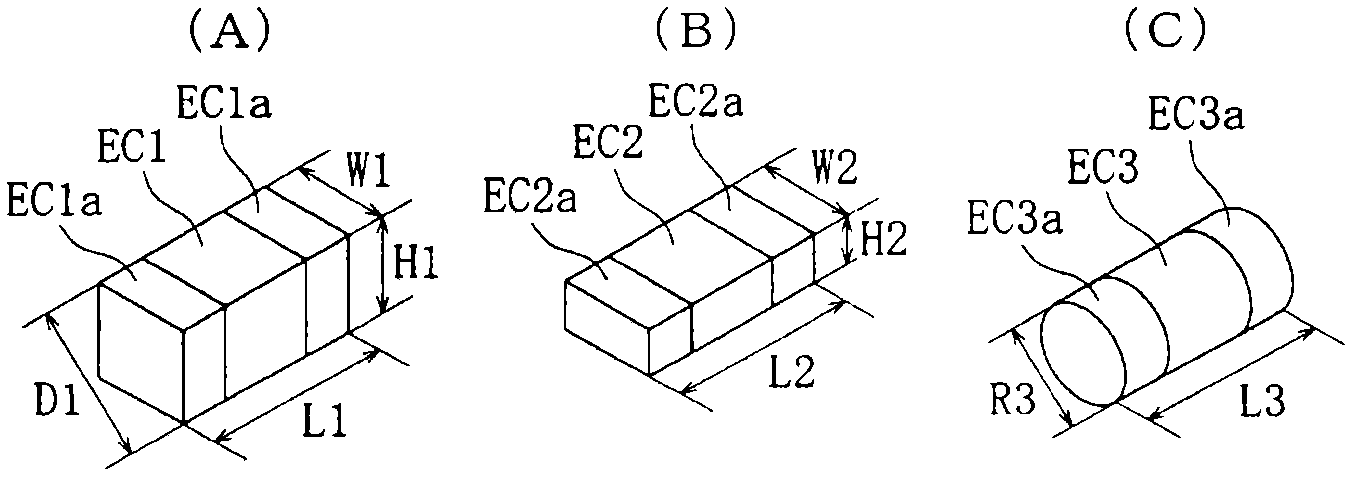

[0053] First, quote figure 1 (A), explain figure 2 (A)~ figure 2 Parts shown in (C) that are to be supplied by the bulk material feeder.

[0054] like figure 1 As shown in (A), the component EC1 is formed in a cuboid shape having a dimensional relationship of length L1>width W1=height H1. Specific examples of this component EC1 are electronic components such as small chip capacitors and chip registers whose length L1 is 1.6 mm, 1.0 mm, 0.6 mm, or 0.4 mm. Any e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com