Damping device having centrifugal force pendulum

A vibration damping device and centrifugal pendulum technology, applied in the direction of rotation vibration suppression, spring/shock absorber, vibration suppression adjustment, etc., can solve the problems of limited mass inertia and reduced efficiency of centrifugal pendulum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

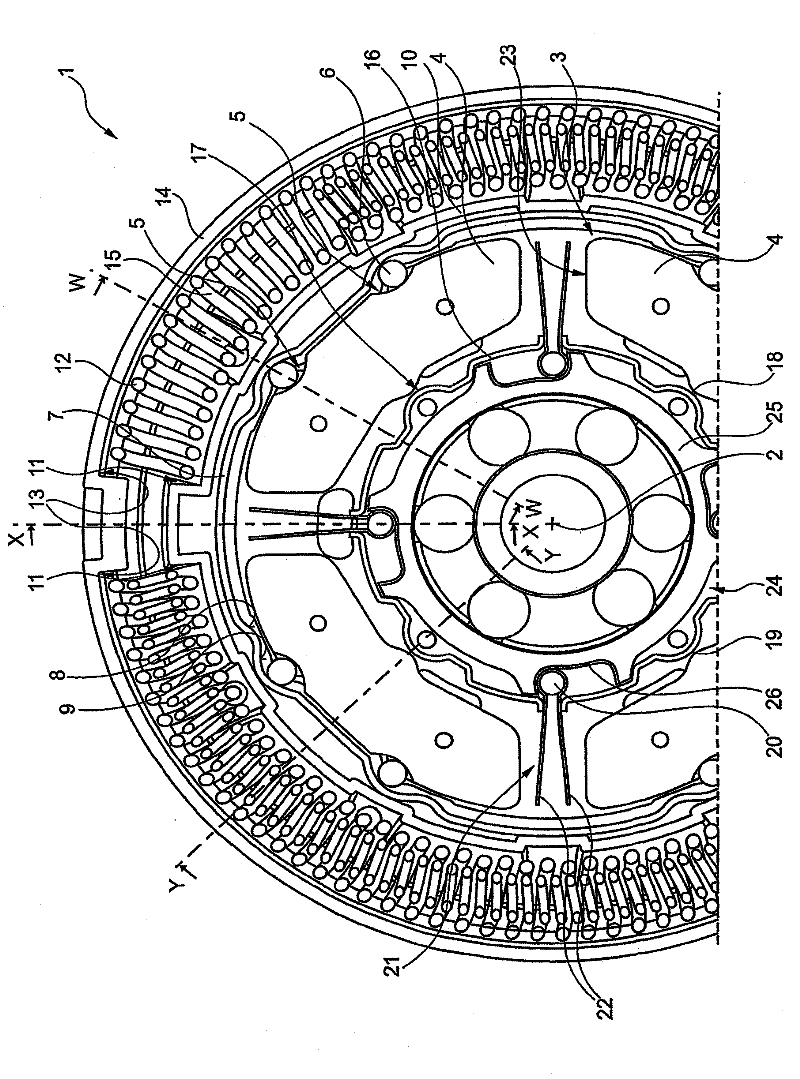

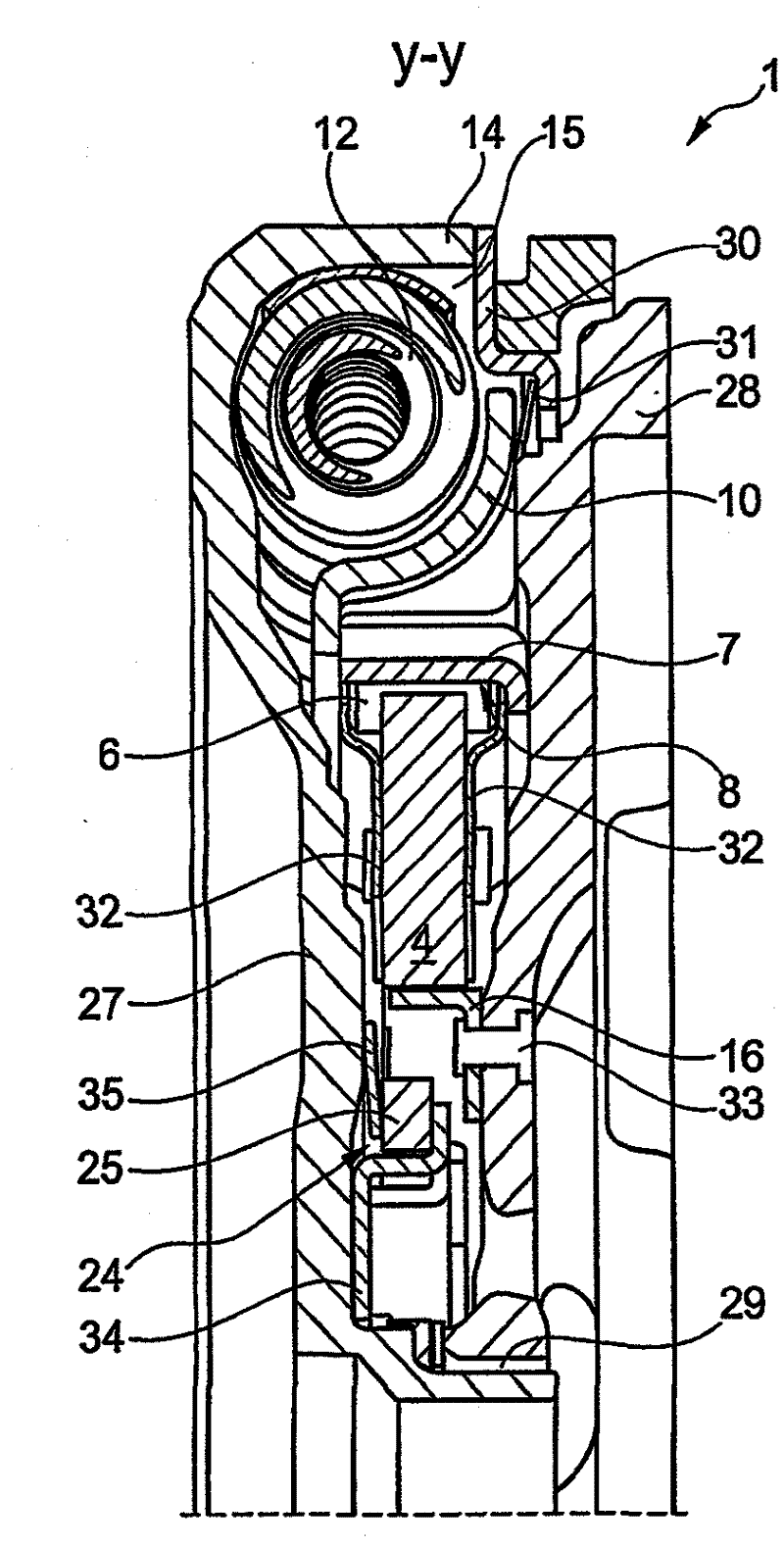

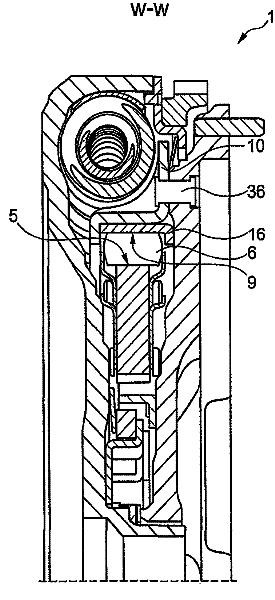

[0013] figure 1 The damping device 1 is shown in a partial view, wherein a section perpendicular to the axis of rotation 2 is drawn and the inner parts of the damping device 1 are thus seen. The damping device 1 comprises a centrifugal pendulum 3 comprising four pendulum masses 4 distributed over the circumference, each of which has two paths of motion 5 radially on the outside, formed in the exemplary embodiment shown by rollers The rolling body 6 rolls on the moving track 5. On the diametrically opposite side, a ring element 7 is provided, which has a receiving profile 8 with a movement path 9 complementary to the movement path 5, on which the rolling bodies 6 also roll, This allows the pendulum mass 4 to pivot relative to the ring 7 up to a maximum pivot angle.

[0014] The ring part 7 is fixedly connected to a radially inner molded part 10 which is assigned to the secondary flywheel mass of the damper device 1 and which has a loading area 11 for an energy store 12 desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com