Through-flow structure of medium-pressure steam extraction opening of steam turbine

A steam extraction port and steam turbine technology, applied to mechanical equipment, engine components, machines/engines, etc., can solve the problems of large energy loss in the extraction chamber, affecting the owner's economic benefits, and insufficient output of small steam turbines, etc., to achieve aerodynamic economy Reduce, reduce the generation and divergence, suppress the effect of vortex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

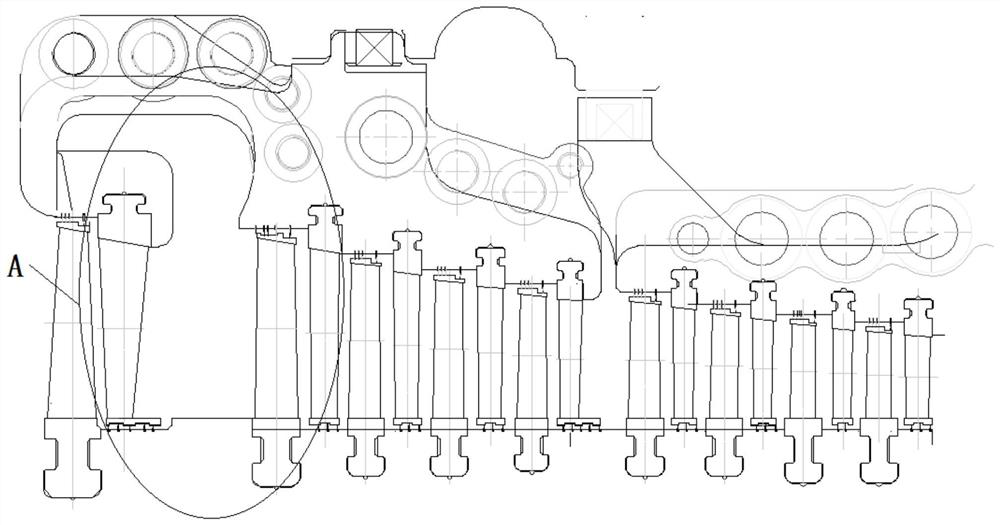

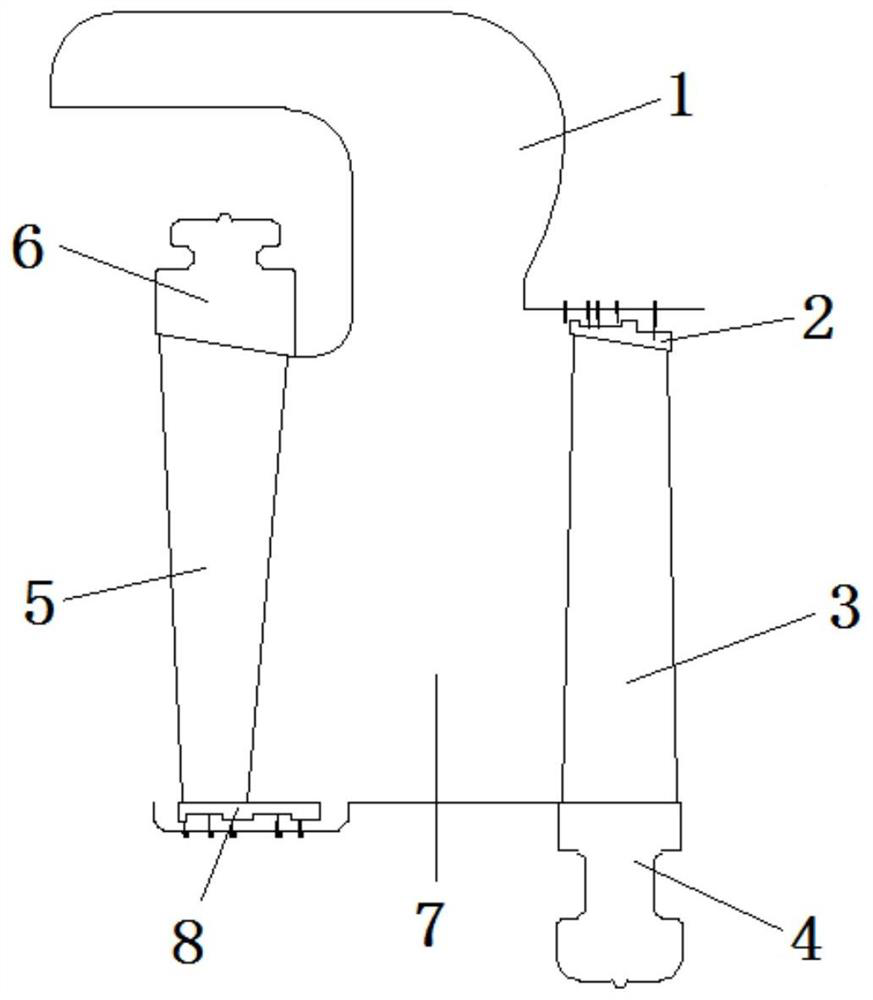

[0016] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, the flow structure of a steam turbine medium-pressure steam extraction port described in this embodiment, it includes the front moving vane 3 of the steam extraction port and the rear stator vane 5 of the steam extraction port, the front moving vane 3 of the steam extraction port and the extraction port The static vane 5 behind the steam port is relatively installed in the medium-pressure steam extraction port of the steam turbine. The chamber between the moving vane 3 before the steam extraction port and the stationary vane 5 after the steam extraction port forms a moving vane flow chamber 7, and the moving vane 7 before the steam extraction port The steam extraction chamber 1 is formed between the vane 3 and the upper part of the stationary vane 5 after the steam extraction port and the middle pressure cylinder of the steam turbine, and the steam outlet turning of the steam extractio...

specific Embodiment approach 2

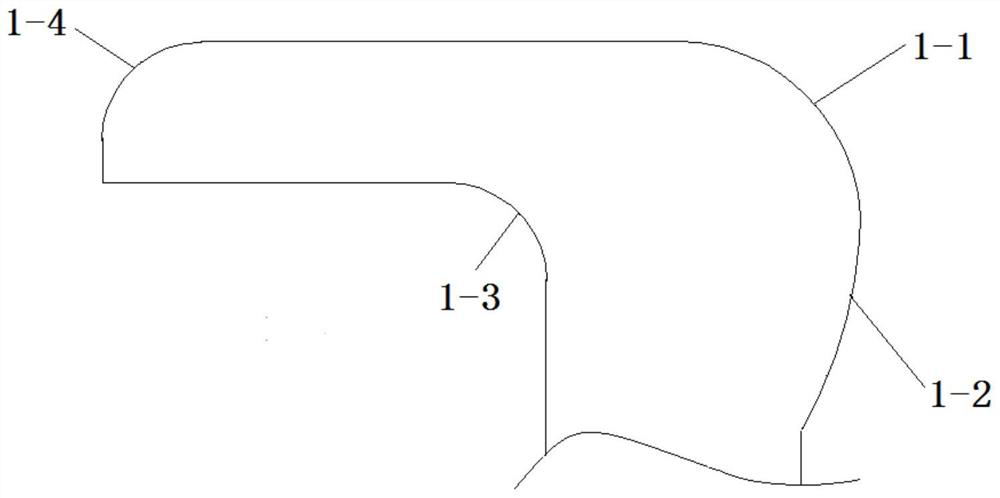

[0017] Specific implementation mode two: combination image 3 Describe this embodiment, the flow structure of a medium-pressure steam extraction port of a steam turbine described in this embodiment, the steam extraction chamber 1 is an integral part, the steam extraction chamber 1 is cast and easy to process, the The outer ring at the steam outlet corner is processed with a first arc 1-1 and a second arc 1-2, and the second arc 1-2 and the first arc 1-1 are sequentially connected along the air outlet direction, and the steam extraction chamber The inner ring of the steam outlet turning point of the chamber 1 is processed with a third arc 1-3, and the others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination image 3 Describe this embodiment, the flow structure of a steam turbine medium-pressure extraction port described in this embodiment, the radius of the first arc 1-1 is 65mm, the radius of the second arc 1-2 is 170mm, and the third circle The radius of arc 1-3 is 35mm, the cavity height at the steam extraction outlet of extraction chamber 1 is 50mm, the cavity width at the extraction inlet of extraction chamber 1 is 90mm, and the diameter of each arc is All are obtained through multiple calculations, in line with the real flow of steam, which not only improves the flow efficiency of the medium pressure cylinder, but also greatly reduces the steam flow loss in the extraction chamber 1 from the perspective of aerodynamic economy. It can better guarantee the use of steam for the small machine after the four-extraction steam extraction, so that the owner can generate more economic benefits, and the others are the same as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com