Flexible manufacturing and precise formulation process for threshing and redrying tobacco leaves

A technology for threshing and redrying and flexible production, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of difficult flexible and precise formula threshing production, many working stations and formulation personnel, and inflexible formula threshing process. To achieve the effect of being conducive to quantitative ratio feeding, improving information traceability, and facilitating the whole process of tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings, but not limited to the embodiments.

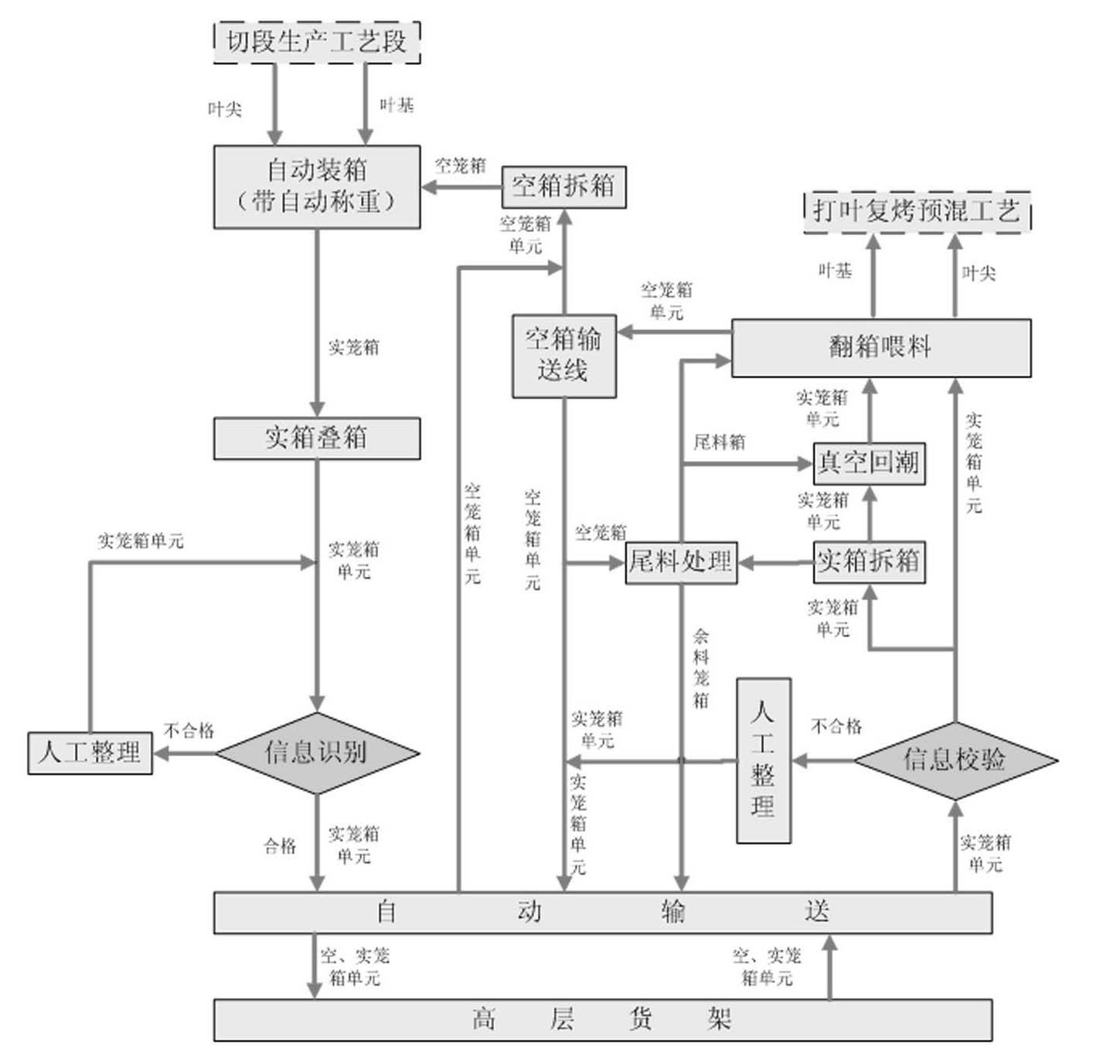

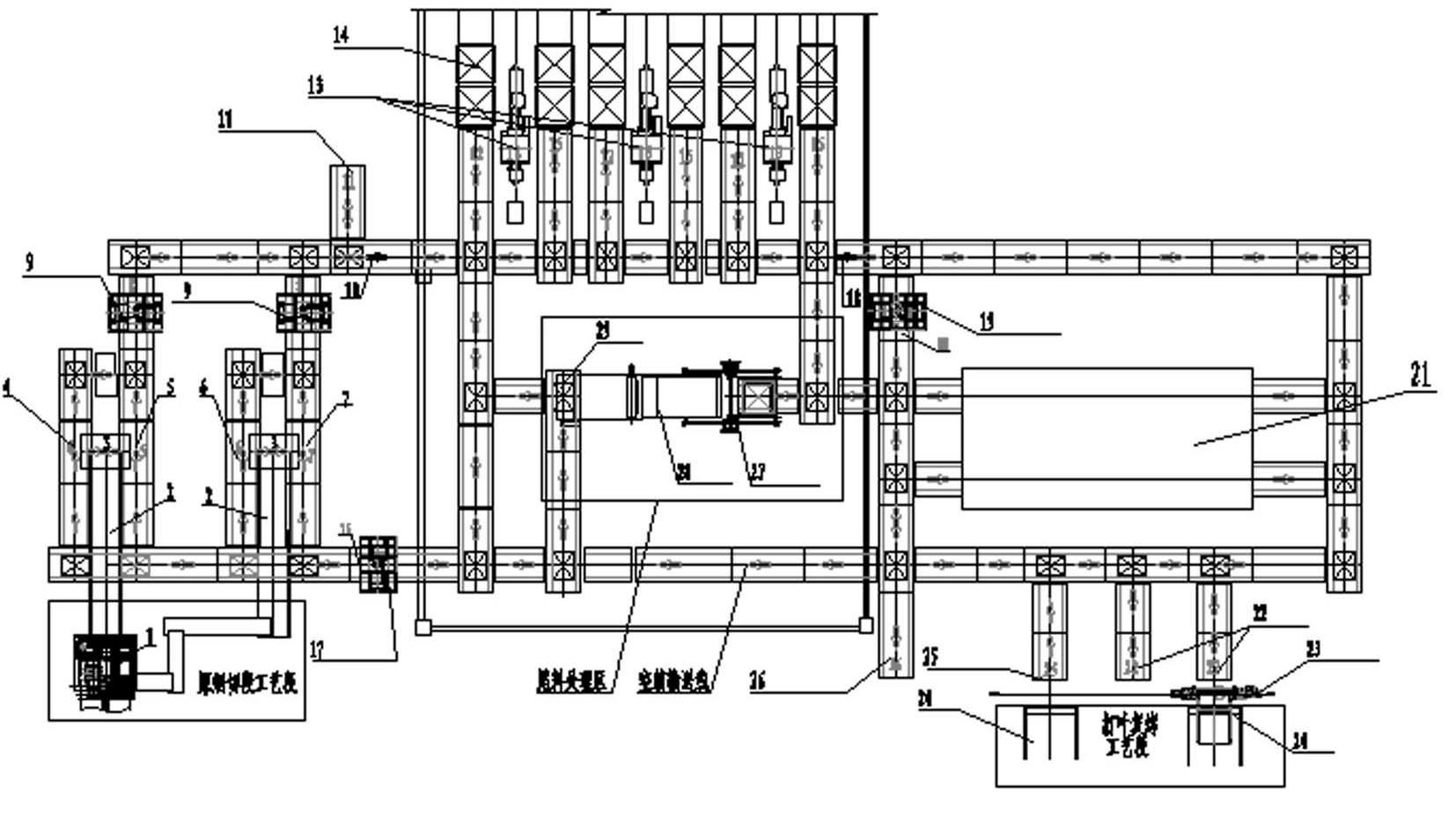

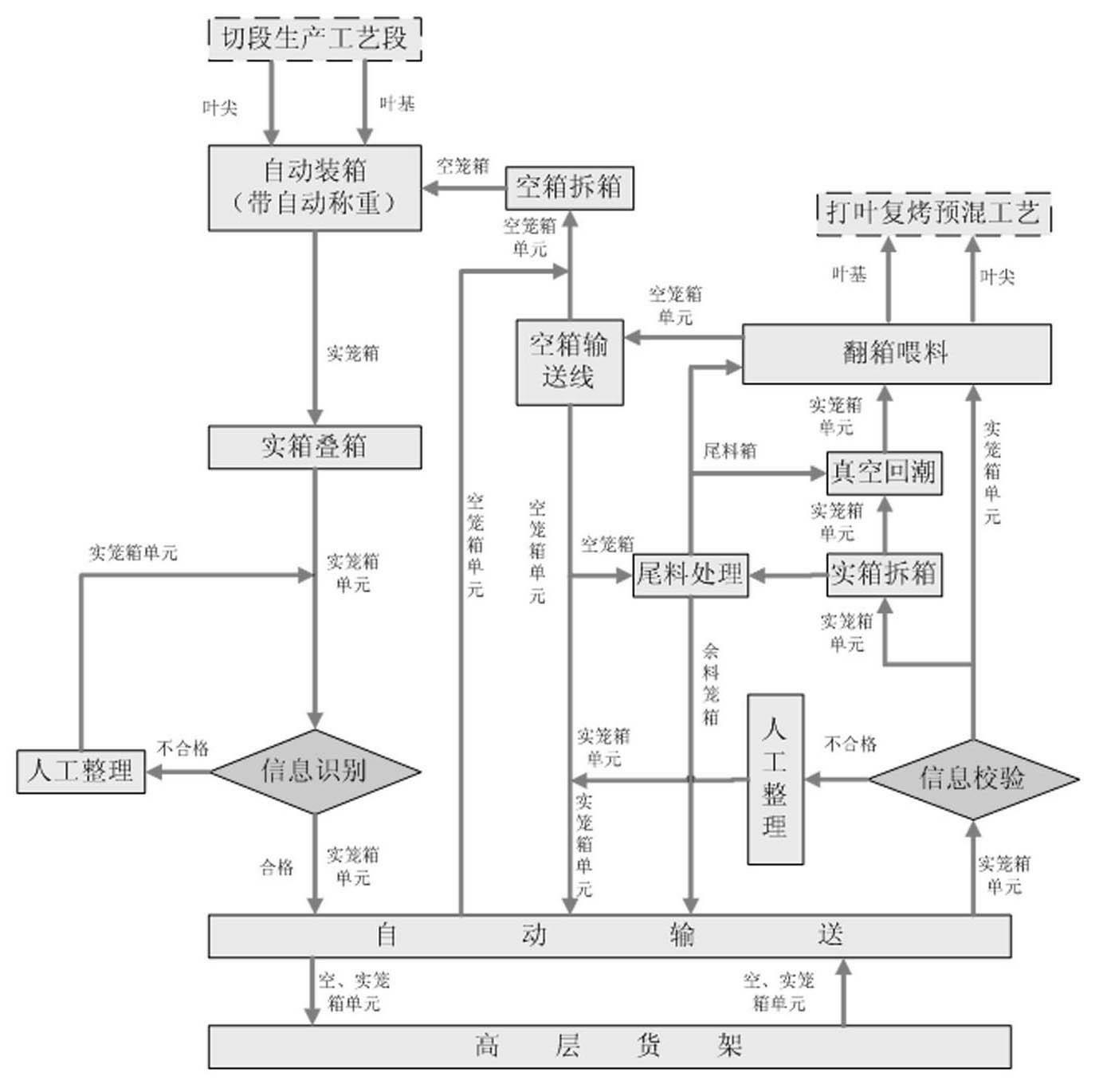

[0016] like figure 1 and figure 2 As shown, the automatic boxing step of the present invention is: first carry out the standardization of materials, according to the requirements of the threshing and redrying process, two types of standardization can be carried out to the materials, one is the standardization of materials that need to be vacuum rehydrated, in the present invention The moisture recovery cage is used as the standard material unit carrier, and the moisture recovery cage has a number for image recognition (it can also paste a barcode or install an electronic label). The cage structure can realize 2 boxes stacking, and it has mesh holes It meets the process requirements of vacuum moisture regain, and its strength can adapt to the clamping operation of the feeding equipment; the other is the standardization of materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com