Passive tire monitoring system

A monitoring system and tire technology, applied in tire measurement, tire parts, generators/motors, etc., can solve problems affecting tire dynamic balance, battery safety hazards, etc., to improve safety, avoid large-scale, and improve information The effect of management level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with embodiment and attached Figure 1-3 The present invention is further explained so that those skilled in the art can implement it with reference to the description. The following examples are only used to illustrate the present invention, but are not intended to limit the scope of the present invention.

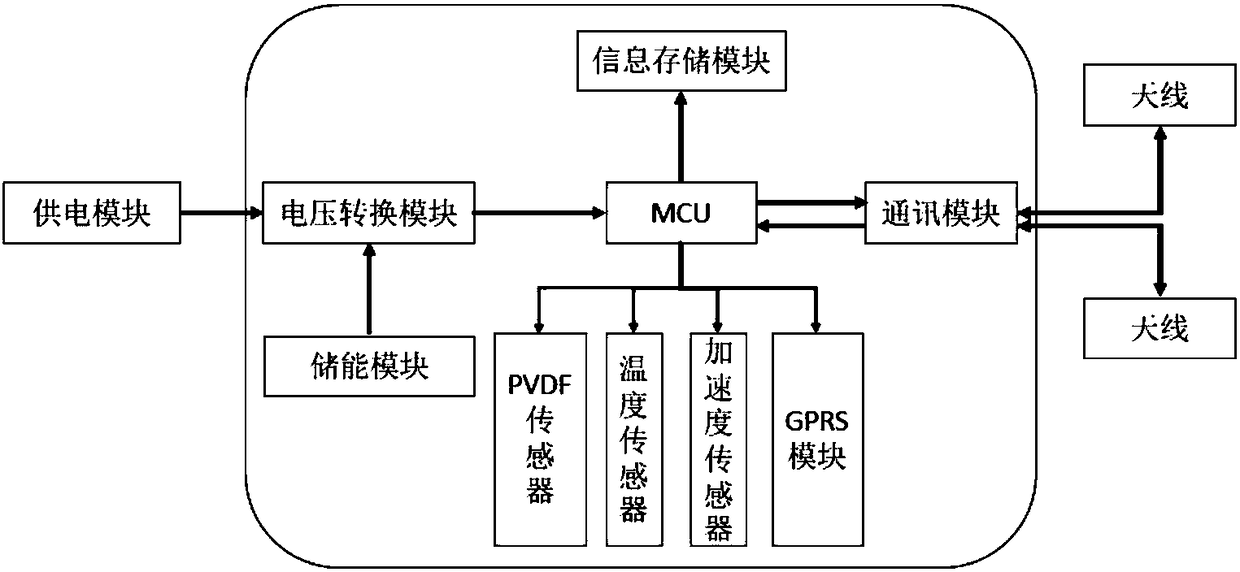

[0019] Such as figure 1 Shown is the system block diagram of the content of the present invention, the whole system is powered by the power supply system, and the power supply system deforms the piezoelectric film sensor through external pressure to generate charges. The power supply module is connected with the voltage conversion module in the RFID chip; the voltage conversion module is connected with the core microcontroller MCU to supply power to the entire RFID chip. The information storage module, communication module, GPRS module, PVDF sensor, temperature sensor, and acceleration sensor are also connected to the core microcontroller MCU...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com