Automatic carbon brush forming machine capable of improving uniformity of structures of carbon brushes

A technology of forming machine and carbon brush, applied in ceramic extrusion die and other directions, can solve the problems of low degree of automation, low production efficiency, short service life and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

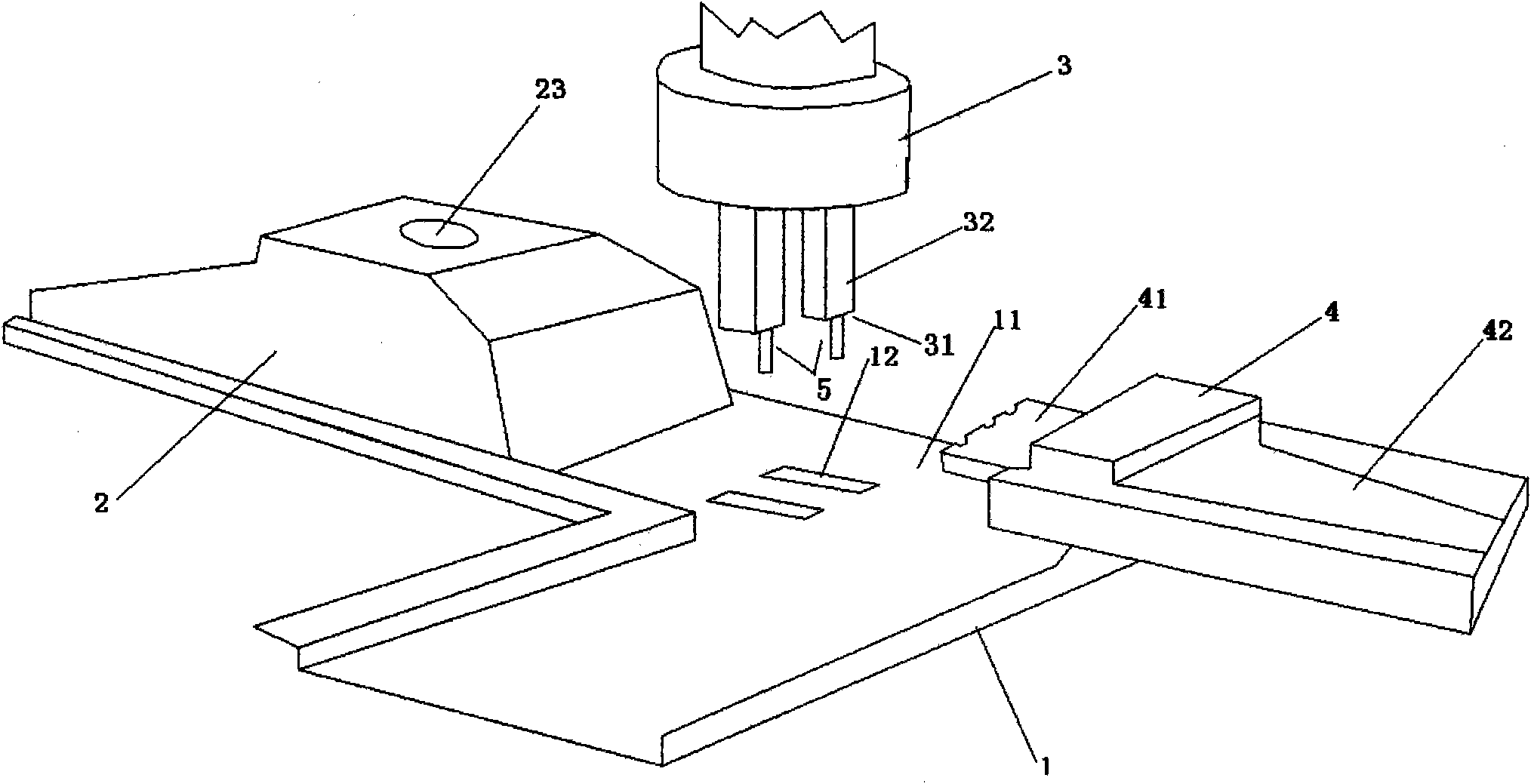

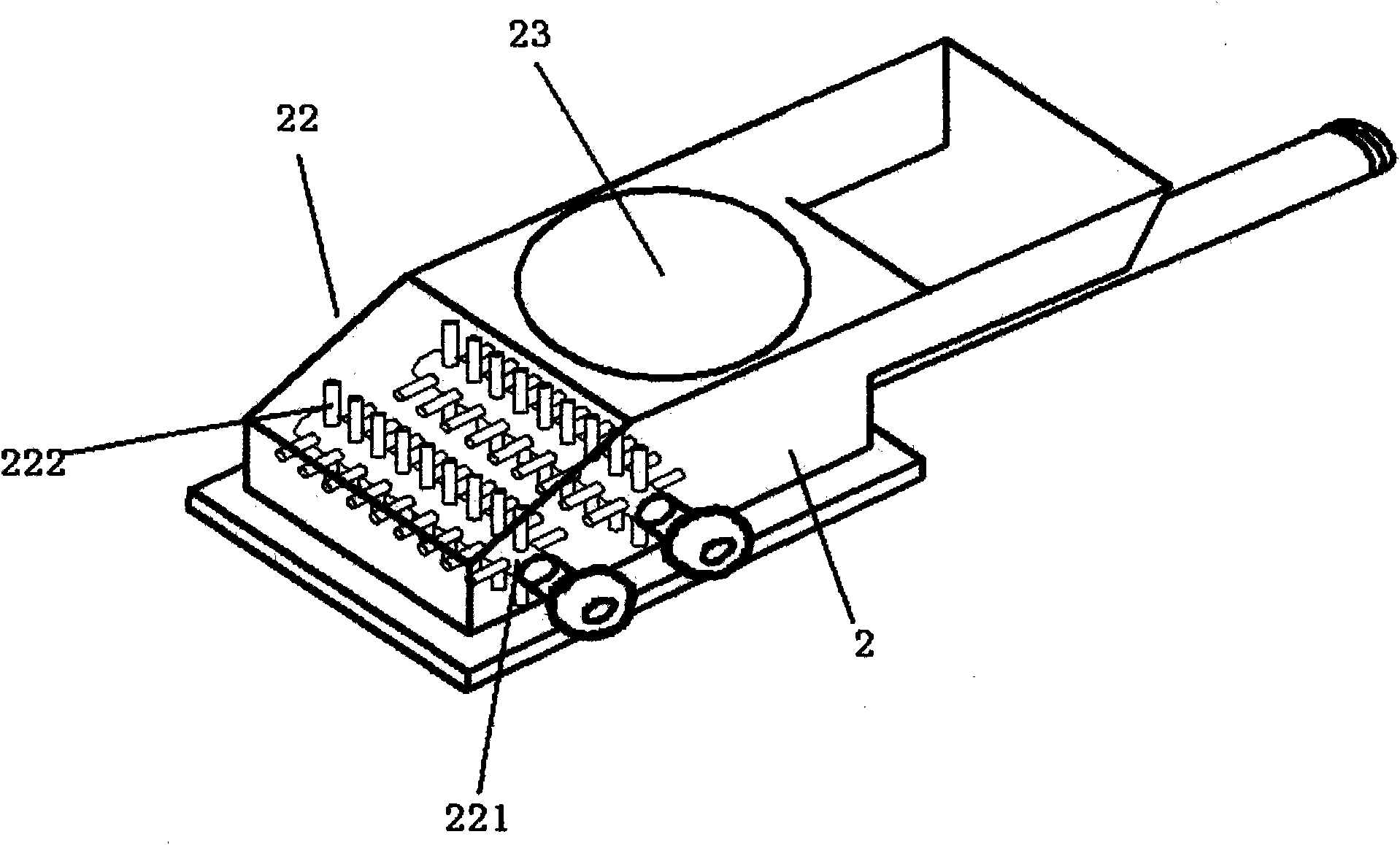

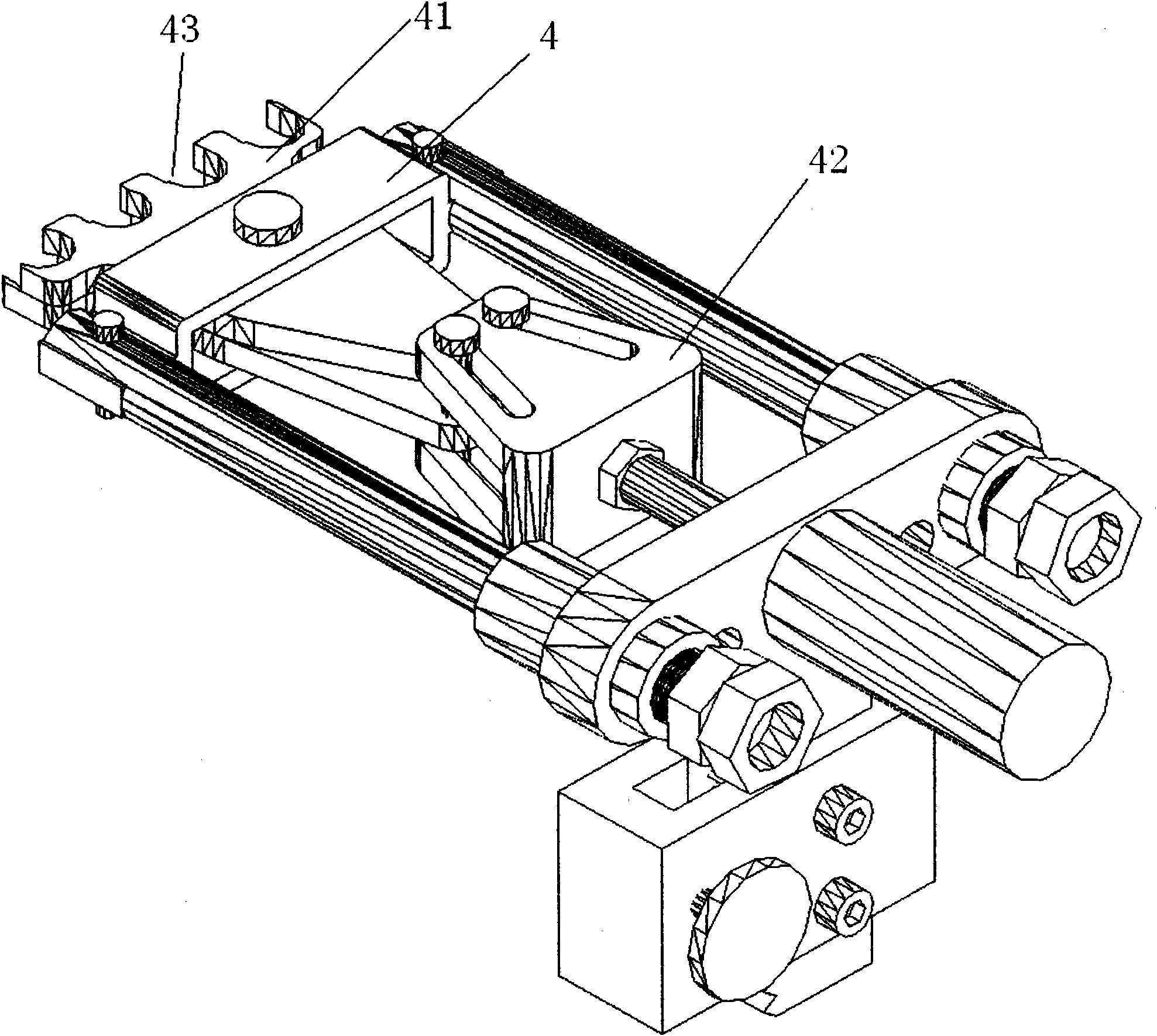

[0035] refer to figure 1 , figure 2 An automatic carbon brush forming machine that contributes to the uniform structure of carbon brushes includes a control system, a workbench 1, a feeding system controlled by the control system, and a pressing system for pressing carbon brushes. The workbench 1 is provided with an upward table 11 . The table top 11 is provided with a feed port 12, and a carbon brush mold is provided below the feed port 12. The feeding system includes a feeding box 2 for accommodating materials, and a discharge port is arranged under the feeding box 2 . The top of the feed box 2 is provided with a material loading port 23 to facilitate loading of materials. Feeding box 2 is positioned on table top 11. The feeding system also i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com