Plate object dividing device

A ring-shaped frame and wafer technology, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of time-consuming segmentation and poor productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

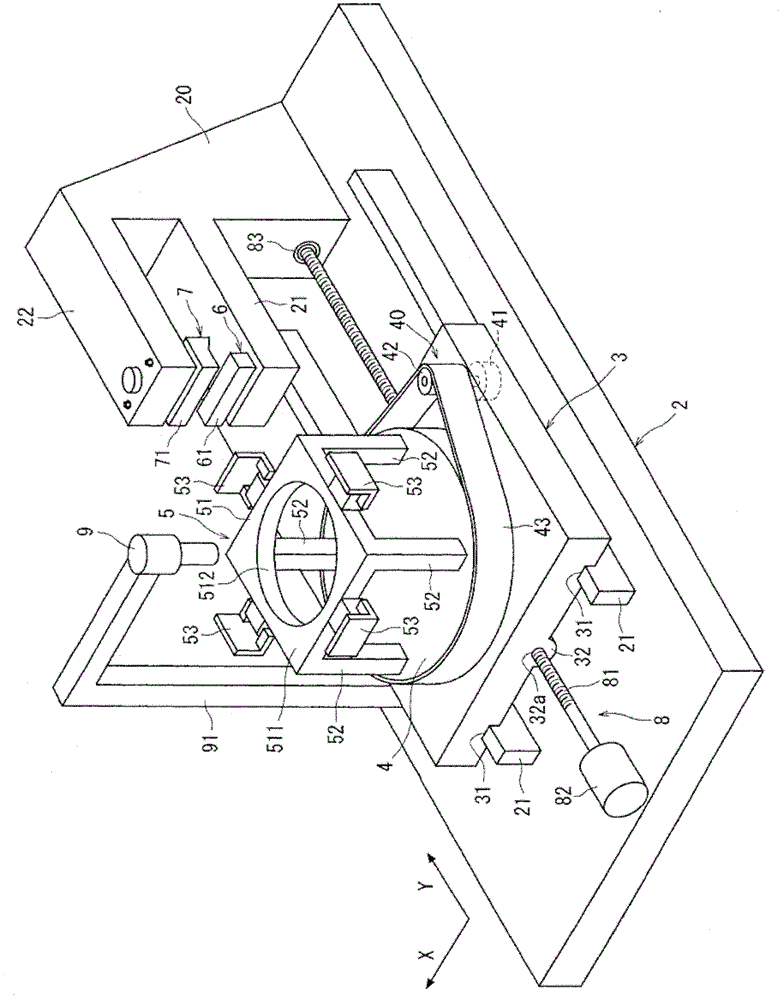

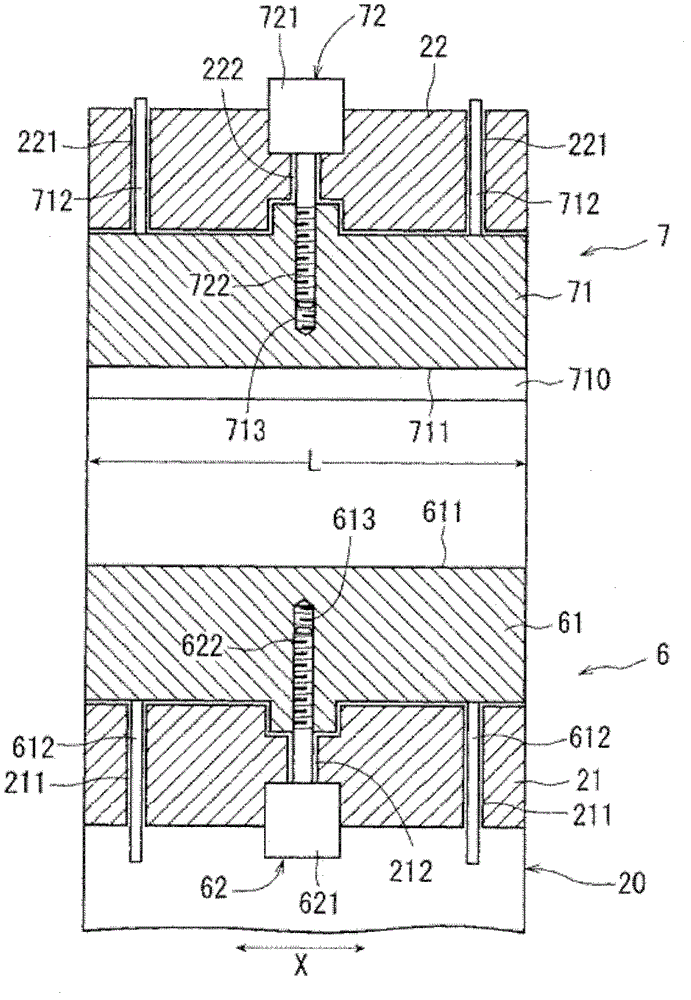

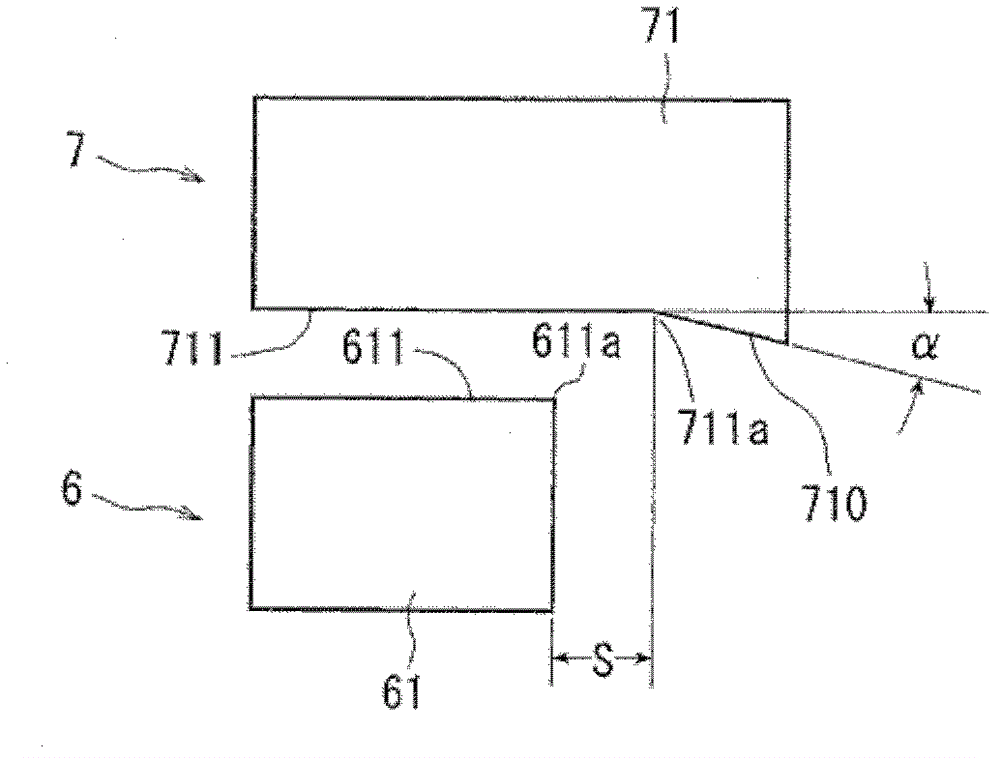

[0035]Hereinafter, preferred embodiments of the plate-shaped object dividing device configured according to the present invention will be described in detail with reference to the drawings.

[0036] First, refer to Figure 5 to Figure 9 A plate-shaped object having a fracture origin formed along a planned dividing line formed parallel to the surface as a workpiece will be described.

[0037] Figure 5 A perspective view is shown of an optical device wafer as a plate-shaped object divided by the plate-shaped object dividing apparatus according to the present invention. Figure 5 The optical device wafer 10 shown is composed of, for example, a sapphire wafer with a thickness of 100 μm, and a plurality of parallel dividing lines 101 are formed in a grid pattern on the surface 10 a. In addition, on the surface 10a of the optical device wafer 10, light-emitting diodes and laser diodes formed by laminating gallium nitride-based compound semiconductors and the like are formed in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com