A flameproof device with an interlocking mechanism

An interlocking mechanism and explosion-proof technology, applied to electrical components, electric switches, circuits, etc., can solve problems such as vacuum tube contact adhesion, breakdown, safety production and personal safety hazards, and difficulty in determining modular feed switches. , to achieve the effect of reducing the volume of the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

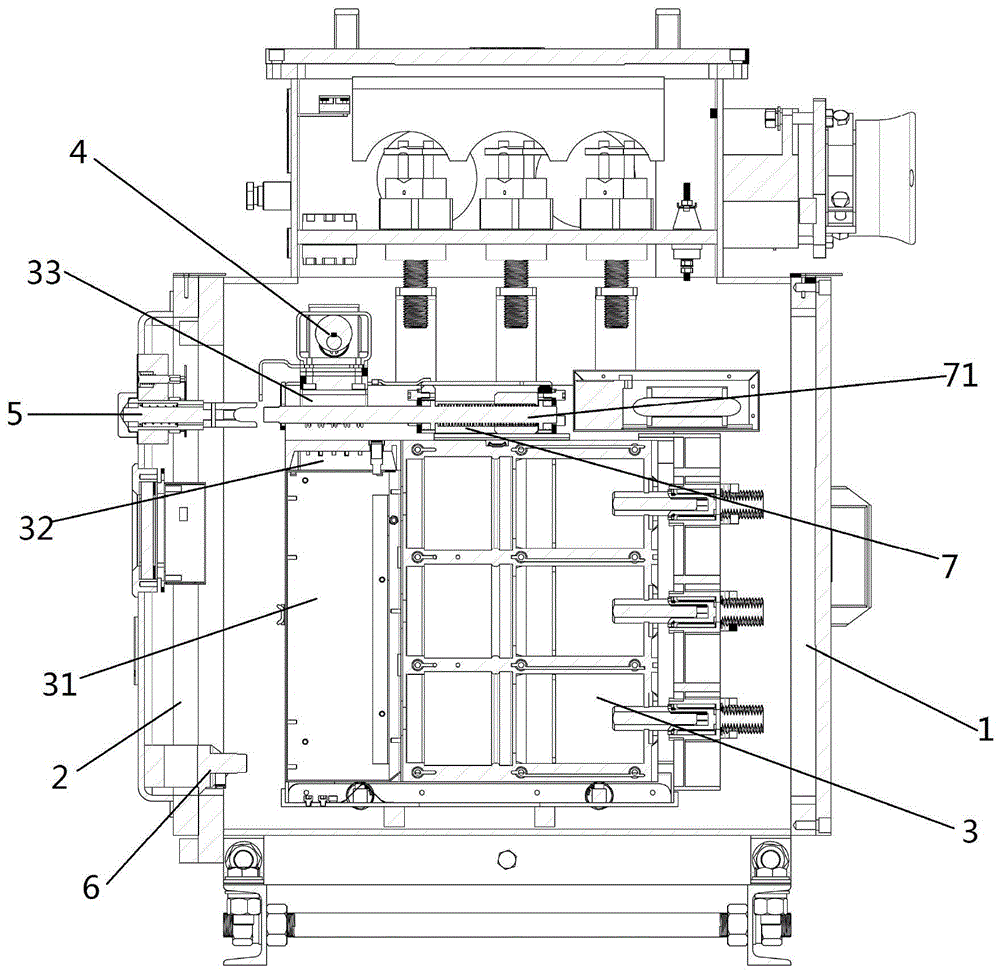

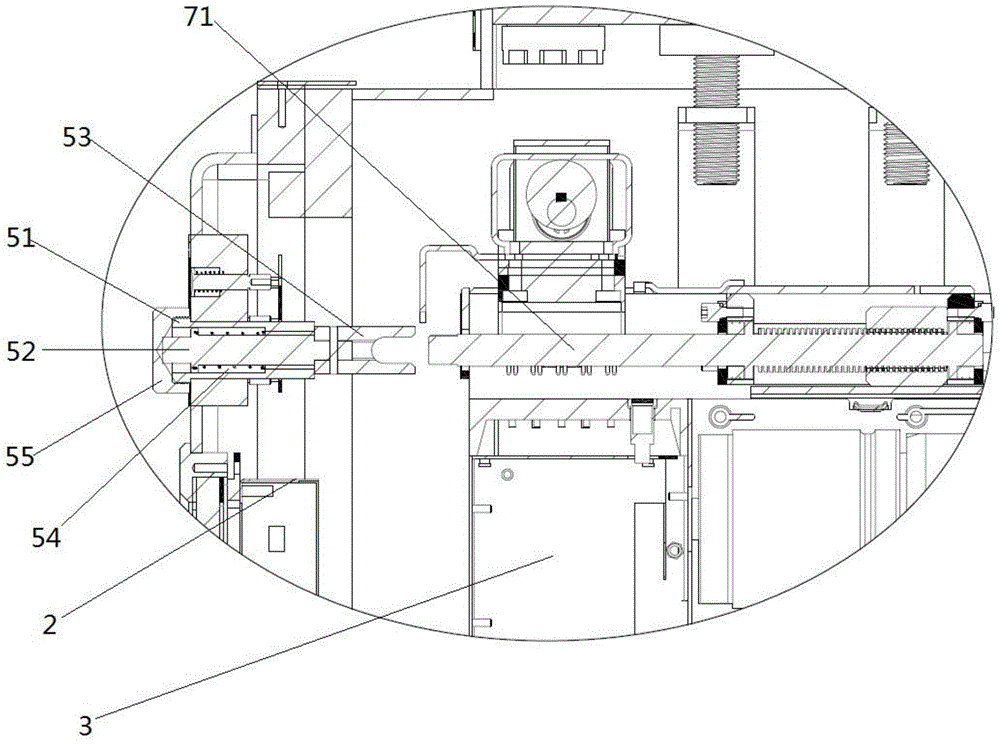

[0030] A flame-proof device with an interlock mechanism comprises a flame-proof casing 1 for placing a modular feed switch 2, a front door 2 arranged on the front side of the flame-proof casing 1, and an interlock mechanism. The interlock mechanism includes a conversion device 4 installed inside the flameproof enclosure 1 for switching on and off the control circuit of the modular feed switch 3, and is installed on the front door 2 for driving the connection between the on and off modular feed switch 3 and the main circuit. The withdrawal mechanism 5 and the locking mechanism 6 used to limit the opening of the front door 2, the conversion device 4 limits the movement of the advancing and withdrawing mechanism 5, and the advancing and withdrawing mechanism 5 limits the movement of the locking mechanism 6.

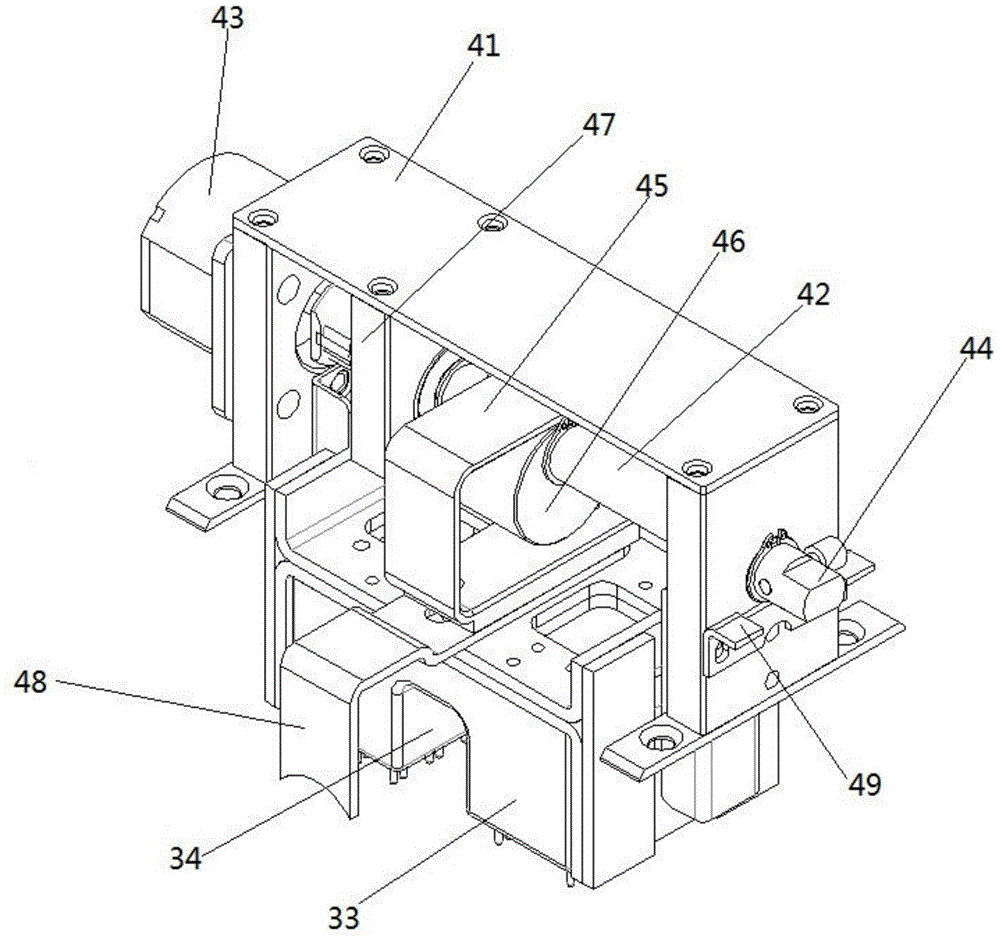

[0031] The control part 31 of the modular feed switch 3 has a static spring needle seat 32 and a dynamic spring needle seat 33, and the conversion device 4 is arranged above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com