Battery box component for electric automobile

A technology for electric vehicles and battery boxes, which is applied to vehicle parts, electric power units, power units, etc., can solve the problems of low efficiency of quick battery box replacement, and achieve the effects of improved quick change efficiency, low production cost, and simple connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

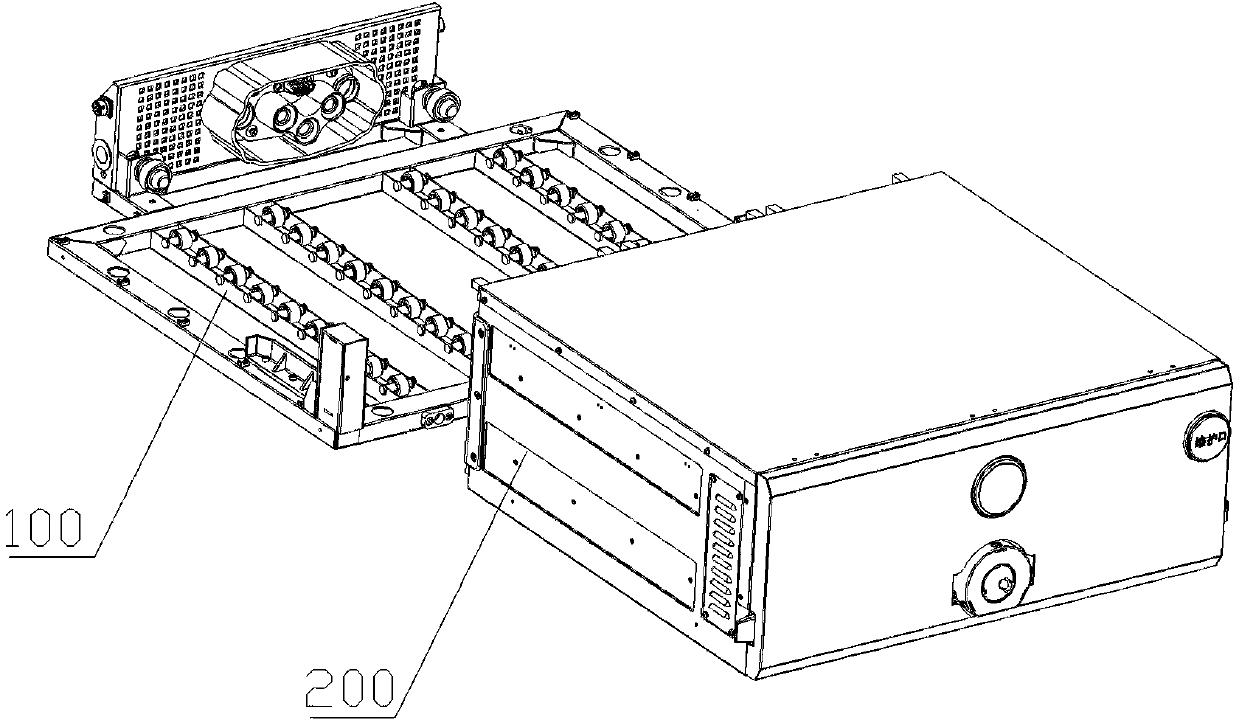

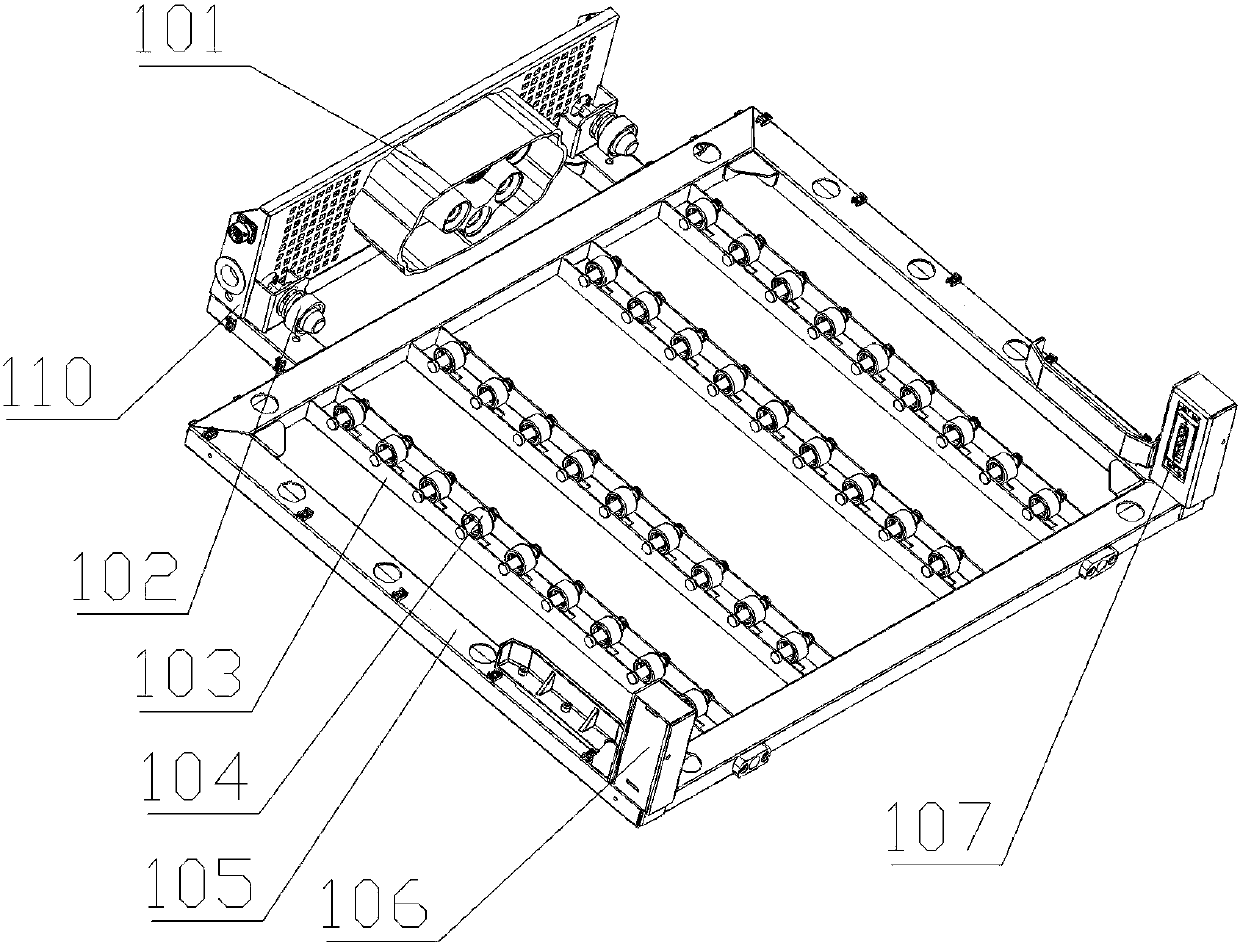

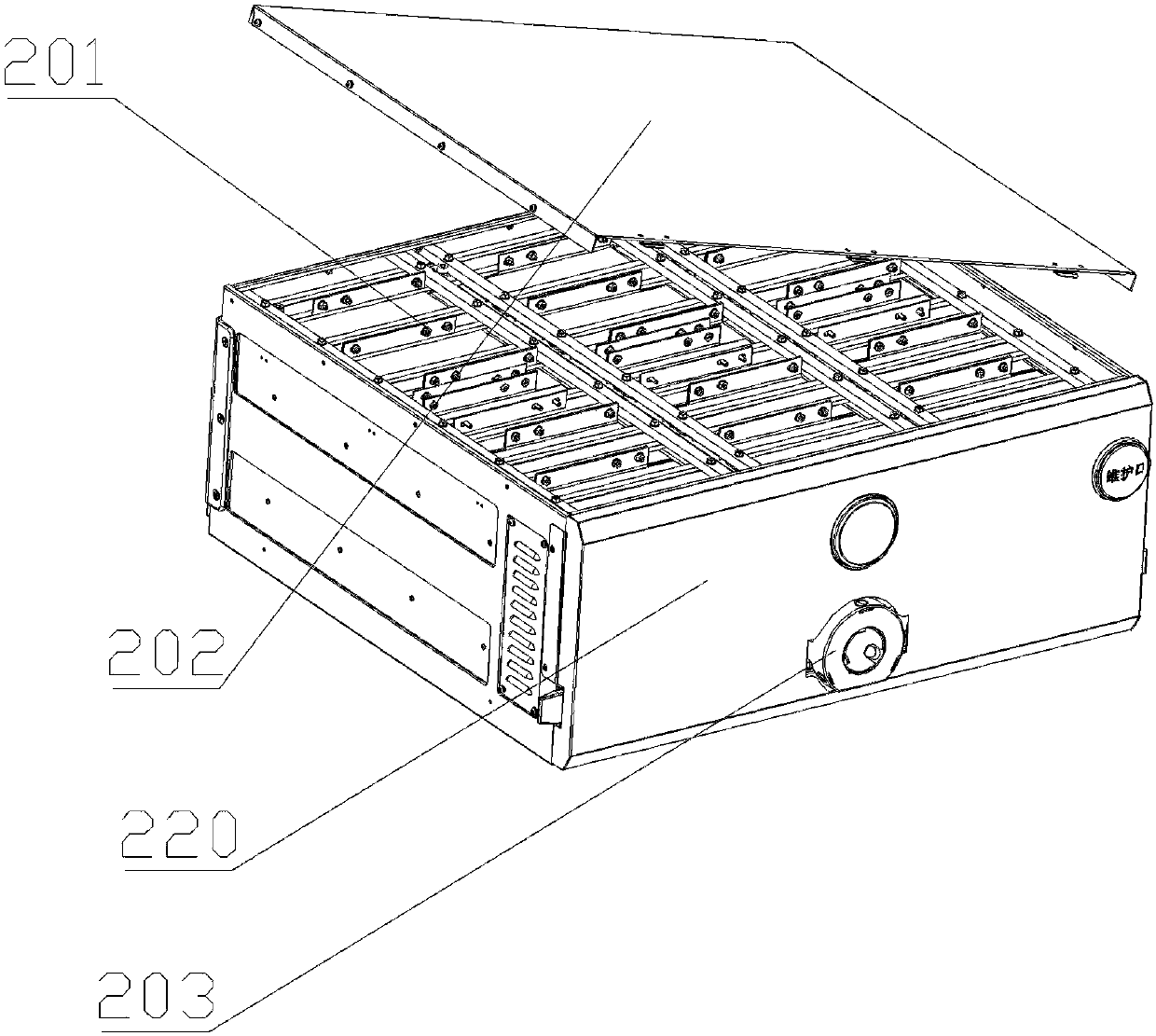

[0028] Such as Figure 1 to Figure 11 As shown, a battery box assembly for an electric vehicle includes a power compartment 100 and a battery box 200 assembled in the power compartment. figure 1The power bin 100 in the battery can generally be divided into two types: rack-mounted power bins and vehicle-mounted power bins. The power bins used in vehicles are usually fixed at the corresponding positions of electric vehicles. The main function is to fix the battery box and pass corresponding The interface realizes the power supply and communication connection of the battery box to the electric vehicle, and the power box for rack loading is usually fixed on the charging rack, and its main function is to fix the battery to realize the charging connection between the battery box and the charging device. In this embodiment, the battery box 200 is a closed box structure. After opening the upper cover 202 of the battery box, it can be seen that the battery pack 201 in the battery box i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap