High-efficiency energy-saving technology for bullet train

A high-efficiency, energy-saving, motor-car technology, applied in the direction of air resistance reduction technology, railway car body, railway car body parts, etc., can solve the problems of changing into power, no resistance, and large wasted power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

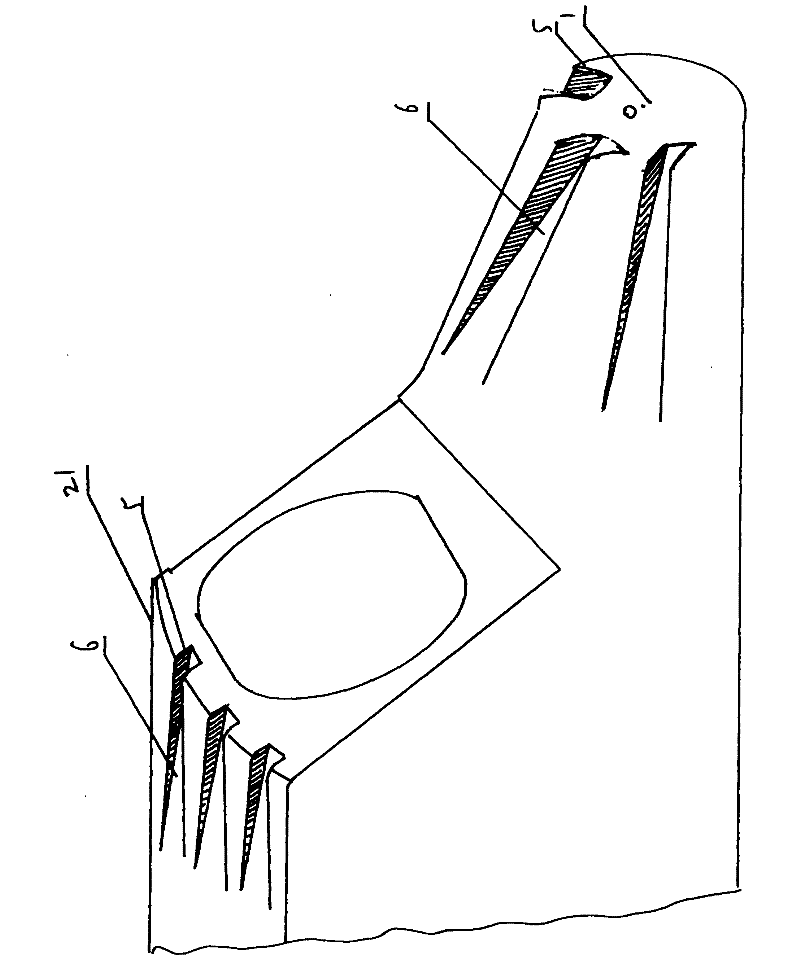

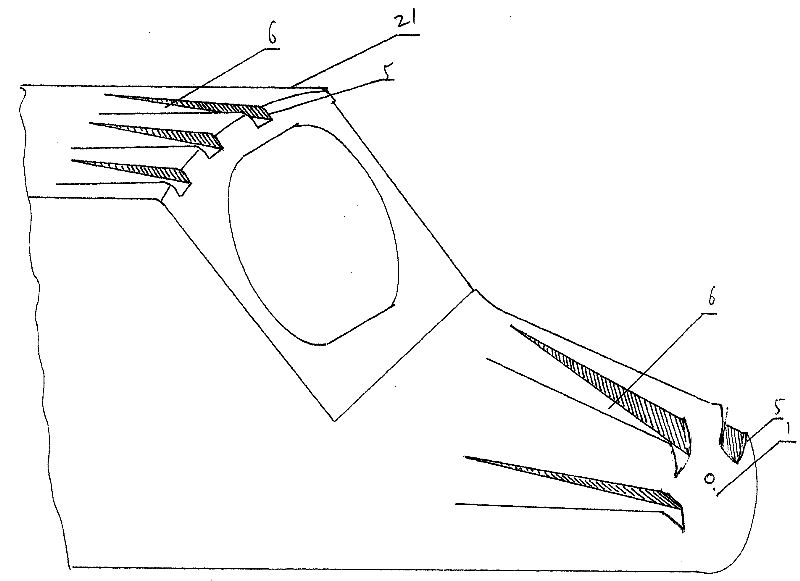

[0023] A high-efficiency energy-saving technology for motor vehicles, such as figure 1 As shown, the high-efficiency and energy-saving technology for motor cars in the first embodiment of the present invention includes a motor car head 1 and a car body 2. The motor car head 1 and the car body 2 are connected or formed as one. The mouth 5 extends backward or is distributed on the car body 2 in a shape of opening and gradually enlarged to form a turbulent flow groove 6, and two side walls 3 are formed in the turbulent flow groove 6, and at least one turbulent flow notch is arranged on the roof 9 7. Extending backward or distributing on the vehicle body 2 with openings gradually enlarged backward to form at least one turbulent groove 8 .

[0024] According to the above-mentioned structure, since there is a turbulent notch 5 on the head 1 of the power-assisted motor car, compared with the conventional motor car, the turbulent notch 5 has the function of decomposing the resistance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com