Transfer device

A transfer device and chute technology, applied in the direction of transportation and packaging, chute, conveyor objects, etc., can solve the problems of motor burnout, affecting the stable supply of production materials, easy to block the chute, etc., to avoid blocking the chute.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

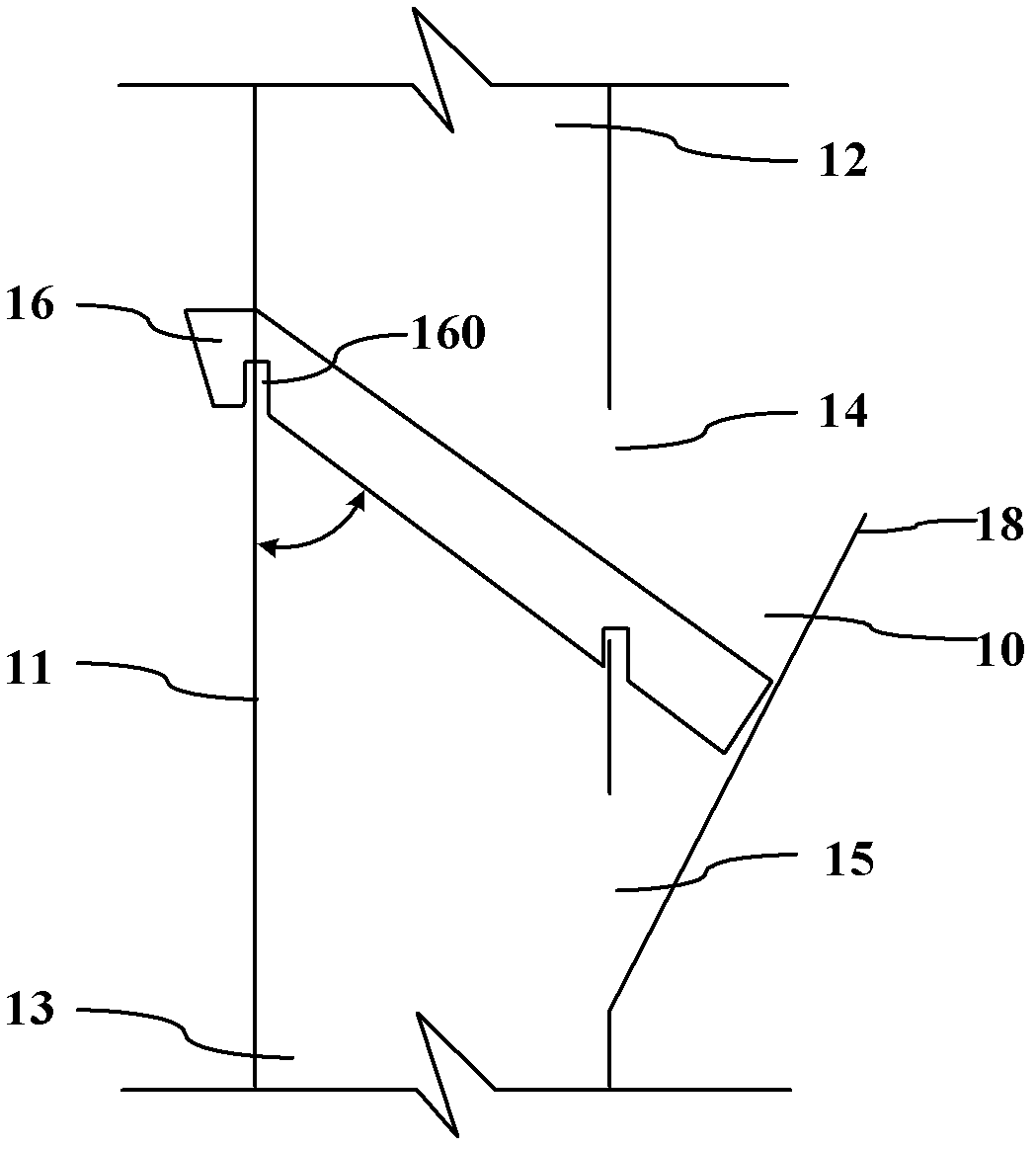

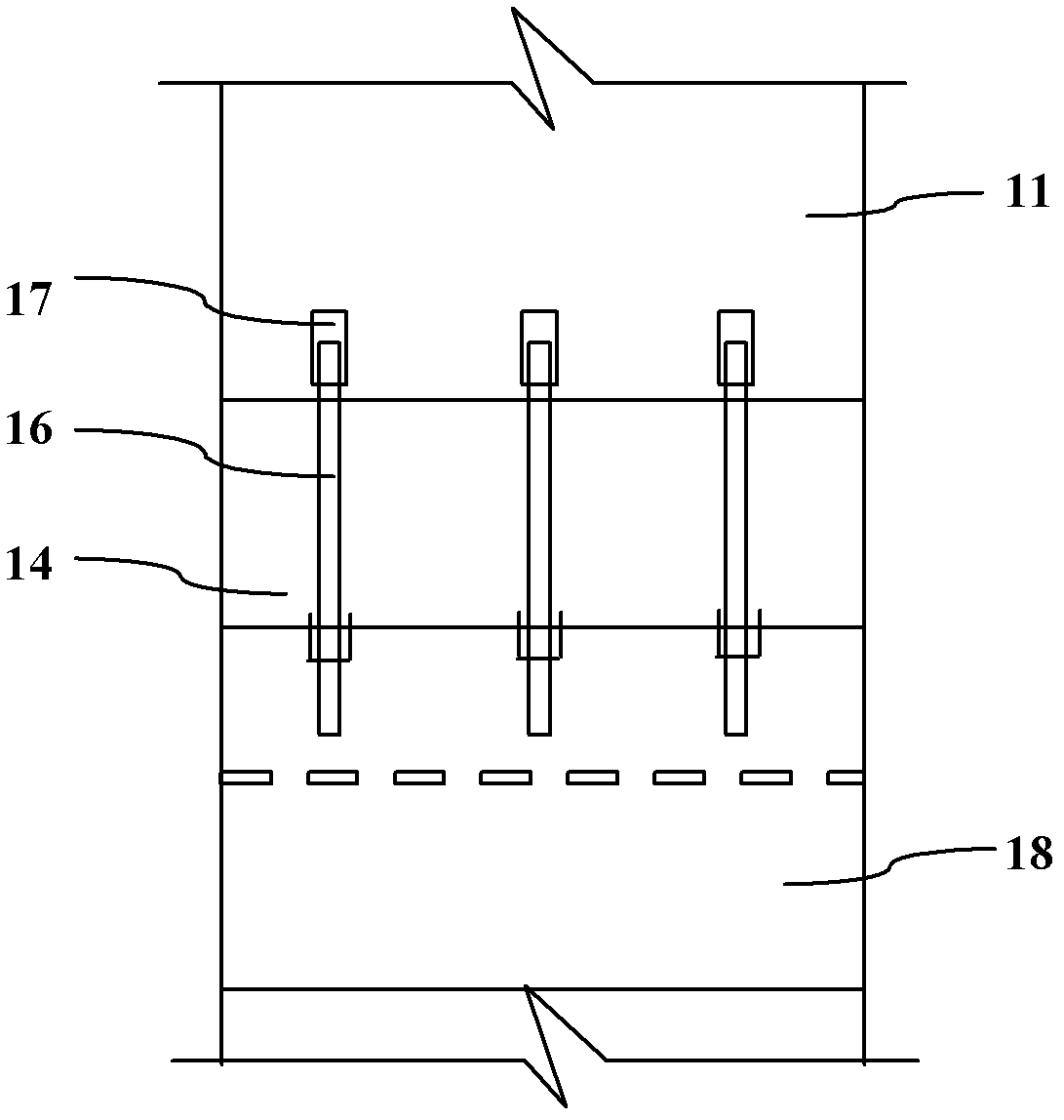

[0029] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides a kind of transfer device, comprises chute 11, material baffle plate 18 and grate plate 16, wherein, chute 11 is arranged between belt conveyor; Material baffle plate 18 is arranged on the outer wall of chute 11, and Surrounded by the outer wall of the chute 11 to form a blocking bin 10, the bottom of the chute 11 and the bottom of the blocking bin 10 are provided with a material return port 15, and the corresponding position with the opening of the blocking bin 10 is provided with a bulk outlet 14; The plate 16 is obliquely arranged inside the chute 11 , and the lower end of the grating plate 16 stretches to the material retaining plate 18 through the bulk opening 14 .

[0030] When the above-mentioned transfer device transmits the production material, the production material enters the chute 11 from the feed port 12, and when passing through the grating plate 16, part of the sol...

Embodiment 2

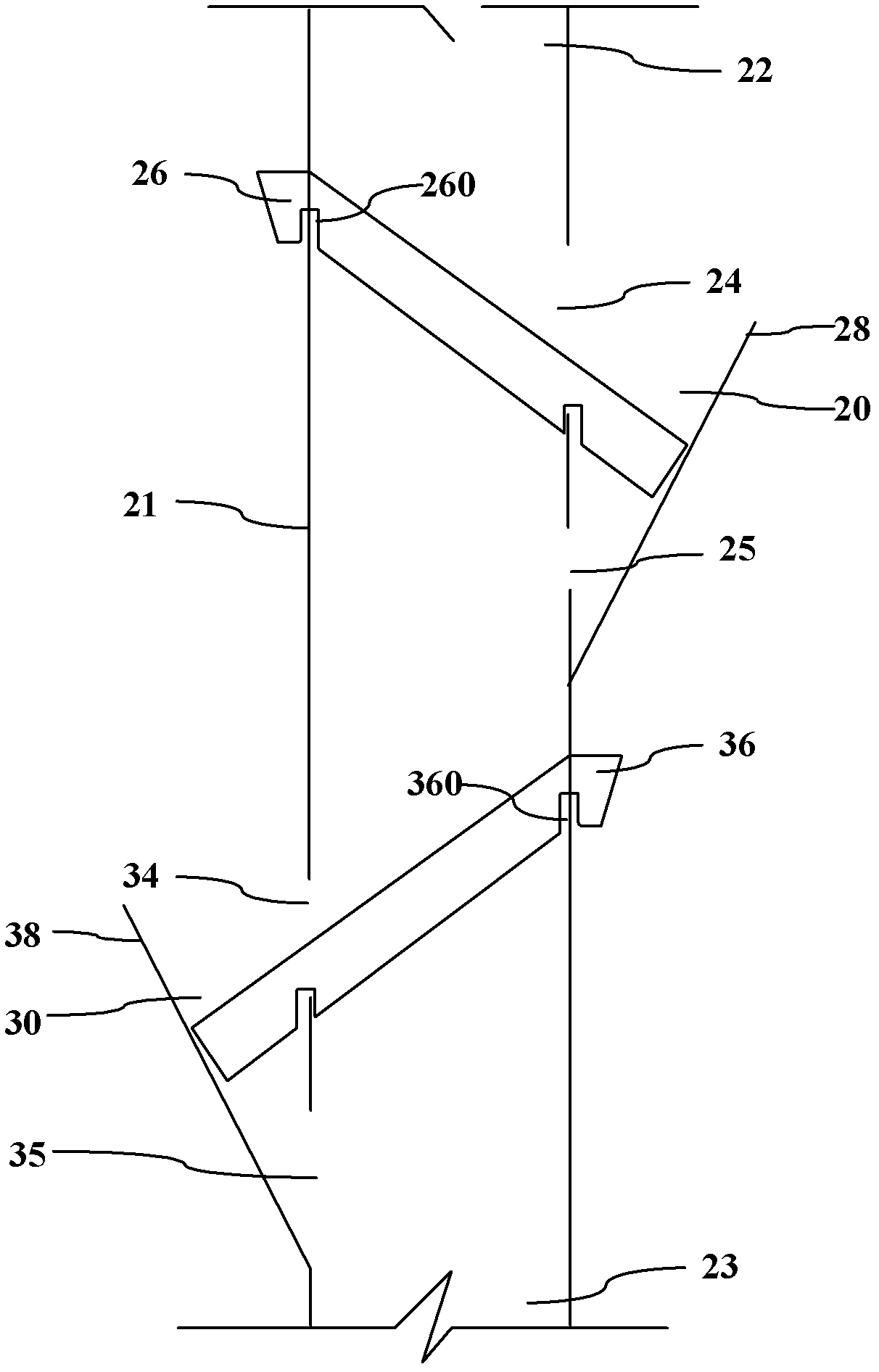

[0036] Such as image 3 As shown, the embodiment of the present invention specifically introduces the situation that two bulk outlets and a material return port are provided on the chute.

[0037] The transfer device comprises a chute 21, a first baffle plate 28, a second baffle plate 38, a first baffle plate 26 and a second baffle plate 36, wherein: the chute 21 is arranged between belt conveyors; the first material baffle plate 28 and the second baffle plate 38 are arranged on the outer wall of the chute 21 respectively, and surround the first chute 20 and the second chute 30 with the outer wall of the chute 21 respectively, the bottom of the chute 21 and the first chute 20 The corresponding position is provided with the first material return port 25, and the opening corresponding to the first blocking bin 20 is provided with the first bulk outlet 24, and the corresponding position of the chute 21 and the bottom of the second blocking bin 30 is provided with the first The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com