Sliding belt cooling machine

A cooler and chute technology, applied in the field of material cooling devices, can solve the problems of easy blockage of the chute of the belt cooler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

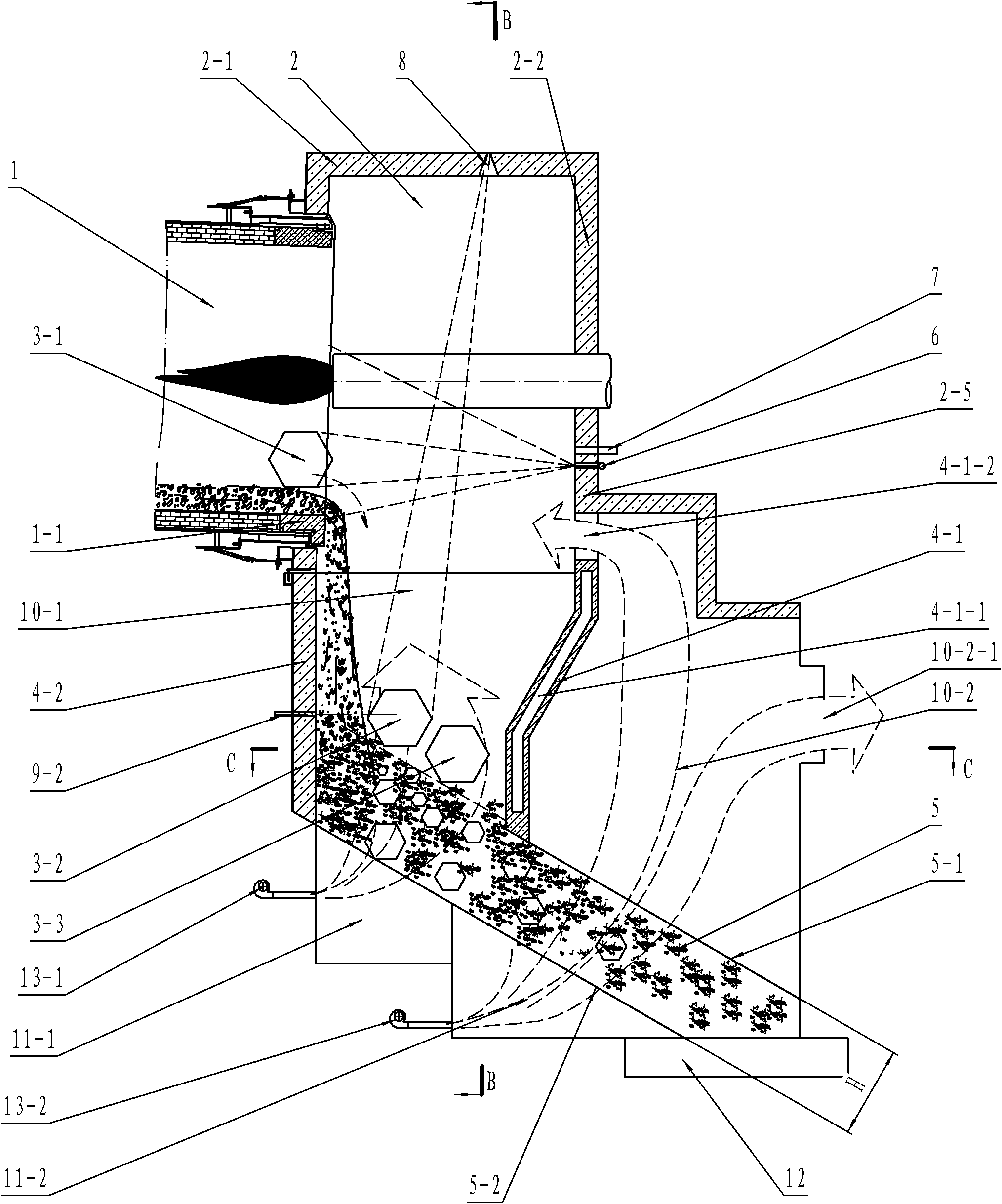

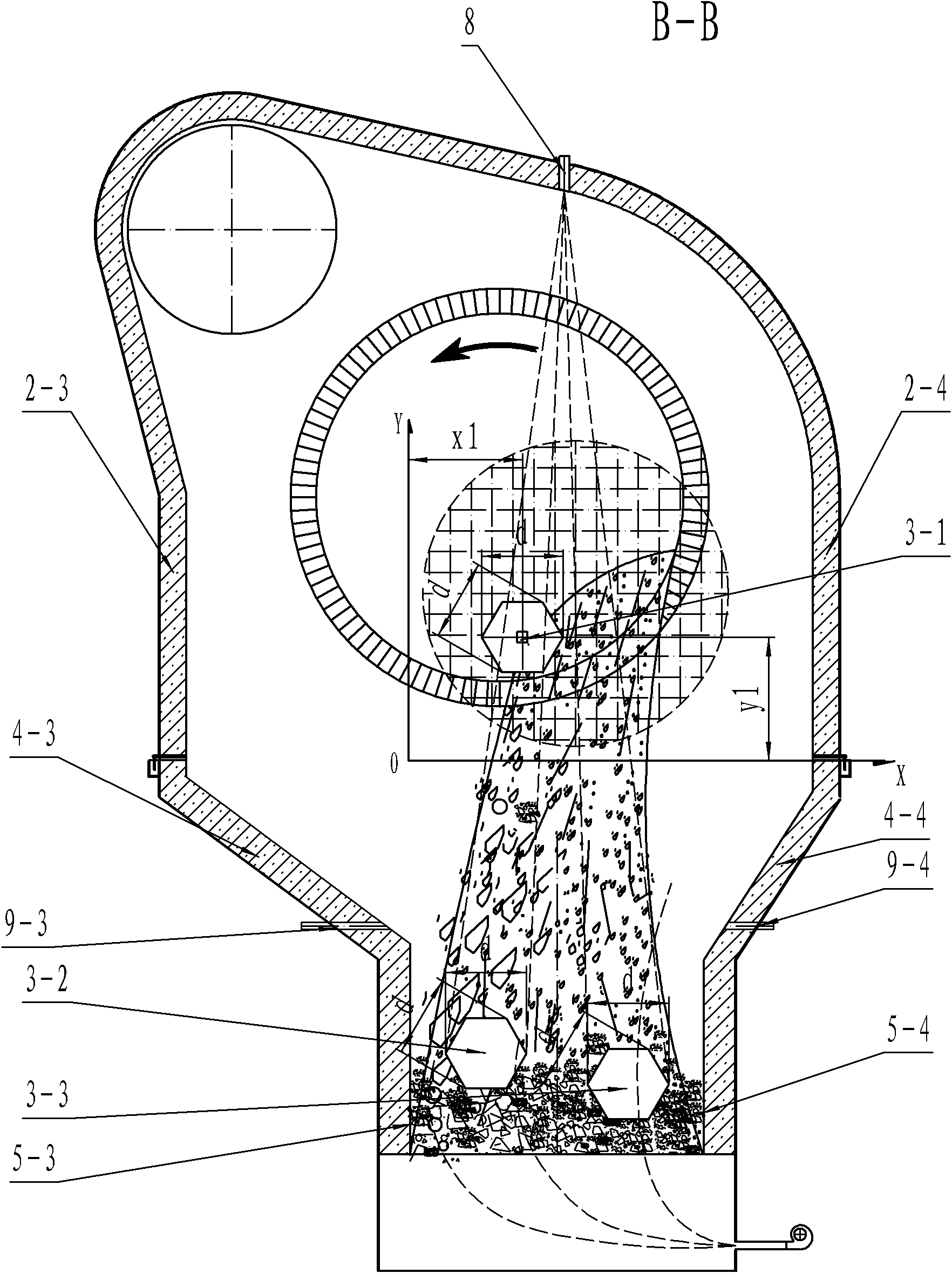

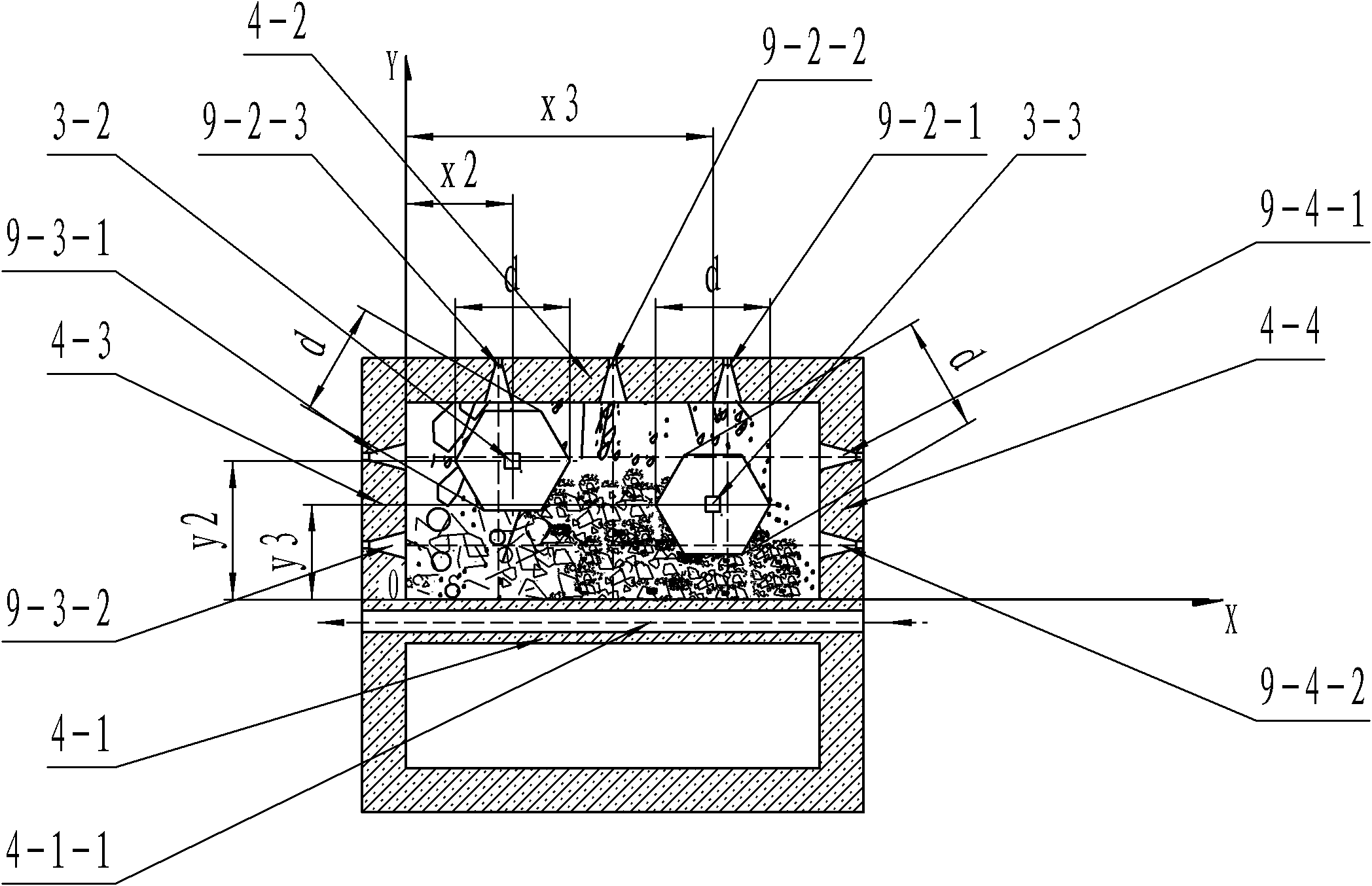

[0058] See figure 1 with figure 2 , is the front structural schematic diagram and the B-B structural schematic diagram of the belt cooler of the present invention. The material fired from the rotary kiln 1 is discharged into the chute 5 through the drainage of the drainage wall, and the material in the chute 5 slides from the inlet end of the chute to the outlet end of the chute by its own weight and is discharged through the unloader 12. When the material is falling, the cooling gas provided by the fan 13-1 and the fan 13-2 cools down the temperature of the material in the chute, so as to achieve the purpose of cooling the material. It can be seen that the entire belt cooler is a non-powered conveying system, and the conveying of materials depends entirely on the gravity of the materials. At the inlet end of the chute, the belt cooler cannot handle it by itself, which will only result in blocking the chute, seriously affecting the production of the belt cooler. Aiming at ...

Embodiment 2

[0084] The difference between this embodiment and Embodiment 1 is that the belt cooler in this embodiment is also equipped with a material level detection device, such as Figure 9 with Figure 10 As shown, the material level at the inlet end of the chute is detected in real time by the material level detection device to ensure that the thickness of the material layer at the inlet end of the chute remains stable. Preferably, ensure that the upper surface of the material layer is slightly lower than the second bulk material on the drainage wall The height of the processing device is to improve the success rate of crushing bulk materials.

[0085] The material level detection device can be the pressure detection device 14 located in the first chute lower chamber 11-1, because the gas pressure in the first chute lower chamber 11-1 is the same as the material layer above the first chute lower chamber 11-1 (that is, the thickness of the material layer at the inlet end of the chute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com